内容

亜鉛メッキコーティング:厚さ、要因、影響

- ジョン

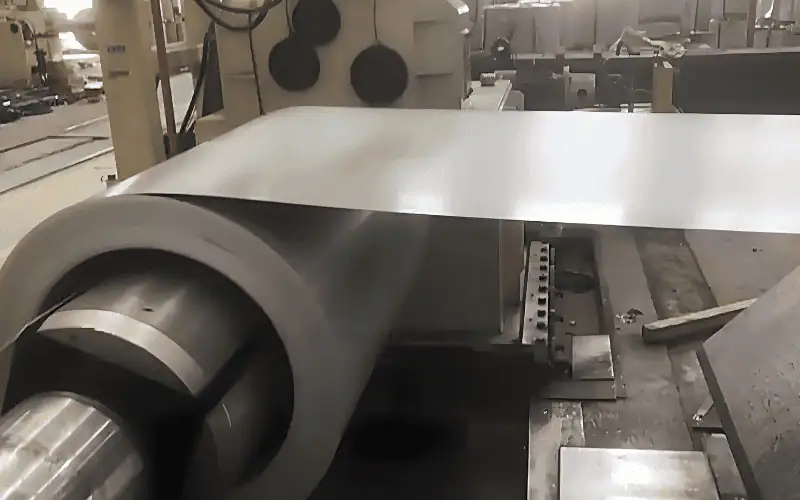

Galvanization is the process of bonding a layer of zinc to steel. A galvanized coating is a protective zinc layer applied to steel to prevent corrosion. The thickness of this zinc layer varies based on factors such as the type of steel, the galvanizing method, and its intended application.

This article will guide you through the different thickness ranges of galvanized coatings, explore the factors affecting thickness and its benefits, and outline methods for measuring it. Additionally, it will introduce standard classifications of galvanized steel such as G30, G40, G60, and G90, each with specific zinc layer thicknesses.

How Thick Is Galvanized Coating

The thickness of galvanized coatings varies based on the galvanizing process, steel type, and applicable standards. Generally, the coating thickness ranges from 5 to over 100 micrometers (µm).

Here is the table for key standards and thickness ranges:

| スタンダード | Thickness Range (µm) |

| ASTM A123/A123M | 45–100+ |

| ASTM A653/A653M | 5–42 |

| ASTM B633 | 5–25 |

| ISO 1461 | 45–85+ |

| ISO 2081 | 5–25 |

| GB/T 2518-2019 | 20–60 |

| GB/T 15675-2020 | 2.5–20 |

In the ASTM A653/A653M standard, galvanized steel is categorized based on coating weight. It is represented by designations such as G30, G40, G60, and G90. Here are their typical coating thicknesses:

| Designation | 亜鉛メッキ重量 |

| G30 | 0.30 oz/ft² |

| G40 | 0.40 oz/ft² |

| G60 | 0.60 oz/ft² |

| G90 | 0.90 oz/ft² |

Factors Affecting Zinc Coating Thickness

The primary factor influencing the thickness of a zinc coating is the galvanizing method used in production. Each method creates a different layer thickness due to its unique process characteristics. The table below shows how various galvanizing techniques affect the resulting zinc layer thickness.

| 亜鉛メッキ | Thickness Range (µm) |

| 溶融亜鉛めっき | 45–100+ |

| Continuous Hot-Dip Galvanizing | 5–42 |

| 電気亜鉛メッキ | 2.5–25 |

| 機械めっき | 12–25 |

| Metalizing | 50–150+ |

| シェラダイジング | 10–30 |

Among these processes, the most widely used methods are hot-dip galvanizing and electro-galvanizing. In the following sections, we’ll explore the key factors that impact zinc coating thickness in both hot-dip and electro-galvanized steel.

溶融亜鉛めっき

- Steel Composition

The silicon and phosphorus in steel influence zinc coating thickness. Higher levels of these elements make steel more reactive to molten zinc, leading to a thicker zinc layer.

Silicon is especially impactful. This is known as the “Sandelin effect,” where silicon levels between 0.03% and 0.12% produce accelerated coating growth. Steel with low silicon and phosphorus content tends to form a more controlled and even zinc layer.

- Steel Thickness and Geometry

In hot-dip galvanizing, steel thickness and shape significantly influence zinc coating thickness. Thicker steel sections hold heat longer, allowing more zinc to bond and form a durable coating.

Steel geometry also affects coating distribution. Corners and edges often have thicker layers as they retain more heat, while flat areas generally produce a more even coating.

- Process Controls for Coating Thickness

没入時間: Adjusting the duration that steel stays in the molten zinc bath.

Withdrawal Speed: Controlling the speed at which steel is removed from the zinc bath; slower withdrawal often leads to thicker coatings.

Air or Centrifugal Wiping: Using air knives or centrifuging to remove excess zinc, ensuring a more uniform and controlled layer.

Bath Temperature: Regulating the zinc bath temperature; higher temperatures can increase reactivity, affecting thickness.

電気亜鉛メッキ

Electro-galvanizing generally offers more control over coating thickness compared to hot-dip galvanizing. The zinc coating thickness is typically controlled by the following factors.

- Current Density

Higher current density speeds up zinc ion deposition, creating a thicker coating in less time. However, it can lead to uneven or rough coatings. Slows in the deposition rate can lead to a thinner, more controlled layer.

- Plating Time

Longer plating time allows more zinc to deposit, resulting in a thicker layer. Shorter times produce thinner coatings. Plating time is a straightforward way to control the final thickness based on application needs.

Impact of Zinc Coating Thickness on Steel Performance

耐食性

A thicker coating provides a stronger barrier against moisture and contaminants, reducing the likelihood of rust formation on the steel surface. The additional zinc layer delays the exposure of the underlying steel to corrosive agents.

耐久性と寿命

The thicker the zinc coating, the greater the durability and lifespan of the galvanized steel. Thicker coatings offer prolonged protection, as they take longer to erode in corrosive environments.

For instance, G30 galvanized steel, with a thinner coating, may provide around 5–10 years of protection in moderate environments, while G90 coatings can extend this protection to 20 years or more under similar conditions.

コスト

The thicker the zinc coating, the higher the cost of galvanized steel. Thicker coatings require more zinc, which increases material expenses. Additionally, achieving a thicker layer may involve longer processing times, which can raise production costs.

表面の外観

The thickness of the zinc coating affects the surface appearance of galvanized steel. Thicker coatings often create a rougher, more textured surface, while thinner coatings tend to produce a smoother finish.

This variation in texture influences how well additional treatments, like painting or powder coating, adhere to the surface. Thinner coatings generally allow for a more uniform, aesthetically pleasing finish.

How to Check Galvanized Coating Thickness?

Non-Destructive Methods

- Magnetic Thickness Gauges

This is one of the most popular non-destructive methods. It uses a magnetic probe to measure the thickness of the zinc coating over steel. It’s portable, accurate, and ideal for field inspections.

- Eddy Current Testing

This employs an electromagnetic field to measure thin coatings accurately, often used for electro-galvanized coatings.

- X-Ray Fluorescence (XRF)

It utilizes X-rays to measure both the composition and thickness of the zinc layer. While highly precise, it’s typically used in controlled environments due to the cost.

Destructive Methods

- Microscopic Cross-Sectioning

This involves cutting a sample to measure the zinc layer under a microscope. This provides accurate results but destroys the sample, so it’s used for detailed analysis.

- Weighing Before and After Galvanizing

This measures the weight difference before and after galvanizing to calculate thickness. Though precise, this method is also destructive and mainly used in production settings.

Quality Steel Solution

For reliable, standard-compliant galvanized steel, スチールプログループ delivers high-quality solutions built to meet the demands of your project. Our products are crafted with precision, ensuring exceptional corrosion resistance, durability, and performance. ここをクリック to receive an exclusive discount offer!