Conteúdo

Variações de textura de aço galvanizado, diferentes tipos

- João

O aço galvanizado possui um revestimento de zinco aplicado para protegê-lo da ferrugem. Sua textura superficial pode variar dependendo do processo de galvanização, da espessura do revestimento e da exposição a fatores ambientais.

Este artigo fornece imagens de texturas de diferentes tipos de aço galvanizado, incluindo aço galvanizado por imersão a quente, eletrogalvanizado, corroído e zincado com ferrugem branca. Essas imagens ajudarão você a identificar e comparar as diversas texturas de superfície encontradas no aço galvanizado.

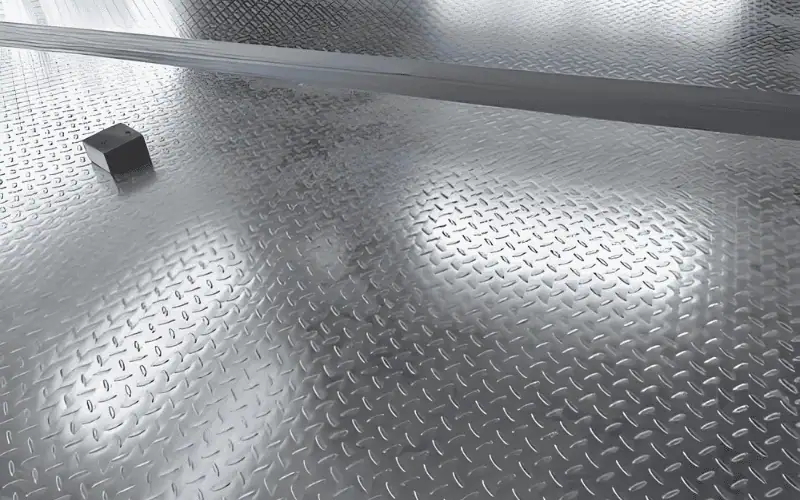

Aço galvanizado (aço galvanizado por imersão a quente)

Aço galvanizado por imersão a quente é um aço revestido por imersão em zinco fundido para criar uma camada protetora. Sua textura superficial é tipicamente áspera e salpicada, com variações dependendo da espessura do revestimento de zinco.

O aço galvanizado a quente recém-produzido normalmente apresenta uma superfície metálica brilhante com lantejoulas visíveis. A superfície também pode parecer ligeiramente áspera, dependendo da espessura do revestimento de zinco, e o acabamento geral é liso com um brilho reflexivo.

Com o tempo, a superfície do aço galvanizado a quente pode sofrer alterações na aparência. Pode perder o brilho inicial e ficar opaca devido à exposição a elementos ambientais como umidade e ar. As lantejoulas ainda podem ser visíveis, mas a superfície pode desenvolver uma aparência mais fosca ou ligeiramente desgastada pelo tempo.

Por que o aço galvanizado a quente desenvolve manchas?

O aço galvanizado por imersão a quente desenvolve flores de zinco devido ao resfriamento e à solidificação do revestimento de zinco. Quando o aço é mergulhado em zinco fundido, ocorre uma reação entre o ferro e o zinco, formando uma camada de liga. À medida que o aço esfria, o zinco puro se solidifica na superfície, formando pequenos cristais que criam o padrão conhecido como flores de zinco.

As lantejoulas aparecem como padrões brilhantes, semelhantes a estrelas, de grãos de zinco. Seu tamanho e visibilidade dependem da temperatura do zinco fundido, da velocidade de resfriamento e de quaisquer traços de metais, como chumbo ou antimônio, presentes no banho. Na produção moderna, o tamanho das lantejoulas pode ser controlado para aplicações específicas.

A razão pela qual as lantejoulas aparecem neste formato específico está ligada à estrutura cristalina do zinco. À medida que o zinco esfria e cristaliza, os átomos se organizam em formas hexagonais devido à estrutura atômica natural do zinco. Esse arranjo atômico cria as formações características, semelhantes a estrelas ou hexagonais.

Aço eletrogalvanizado

O aço eletrogalvanizado recebe uma fina camada de zinco por meio de uma técnica de galvanoplastia. Sua textura superficial é geralmente lisa e uniforme, com brilho menos pronunciado em comparação ao aço galvanizado por imersão a quente.

Aço galvanizado enferrujado branco

A ferrugem branca no aço galvanizado se forma devido a uma reação química entre o zinco e a umidade em condições de baixo oxigênio. Quando exposto à água ou alta umidade, o revestimento de zinco reage produzindo óxido de zinco. Em espaços confinados com fluxo de ar limitado, ele se transforma em hidróxido de zinco, aparecendo como uma camada branca e pulverulenta conhecida como ferrugem branca.

A ferrugem branca é macia, calcária e facilmente visível como uma camada branca ou cinza-clara na superfície do aço. Ao contrário da ferrugem vermelha no ferro, ela não se liga fortemente ao zinco, por isso pode ser removida em estágios iniciais, embora uma ferrugem branca extensa possa enfraquecer a resistência à corrosão do revestimento de zinco.

A aparência única da ferrugem branca resulta da estrutura porosa do hidróxido de zinco, que forma aglomerados macios e irregulares que criam uma aparência pulverulenta. A prevenção envolve manter o aço galvanizado em locais secos e ventilados e evitar a exposição prolongada à umidade durante o armazenamento ou transporte.

Aço galvanizado fortemente enferrujado

Aço galvanizado severamente corroído normalmente apresenta uma superfície áspera e com marcas de corrosão, com sinais visíveis de perda de zinco. A camada protetora de zinco foi amplamente degradada, expondo o aço subjacente.

A superfície pode parecer irregular, com pontos profundos de ferrugem ou áreas onde o metal oxidou. A corrosão frequentemente resulta em uma aparência de ferrugem escamosa, marrom-avermelhada e, em casos extremos, o aço pode apresentar sinais de danos estruturais, como afinamento ou furos.

Perguntas frequentes

O aço galvanizado é áspero?

O aço galvanizado a quente pode ser áspero, especialmente se o revestimento de zinco for espesso. A superfície pode apresentar um padrão salpicado ou leves irregularidades, conferindo-lhe uma aparência texturizada. O aço eletrogalvanizado geralmente é mais liso.

Por que o aço galvanizado parece irregular?

O aço galvanizado pode apresentar irregularidades devido a variações no revestimento de zinco. Isso pode ocorrer com o aço galvanizado por imersão a quente se o revestimento for irregular ou se esfriar de forma inconsistente, fazendo com que algumas áreas pareçam mais brilhantes ou foscas.

O aço galvanizado é brilhante ou opaco?

O aço recém-galvanizado (por imersão a quente) é brilhante e tem aparência metálica, com uma superfície reflexiva. Com o tempo, torna-se mais opaco devido à oxidação do zinco, mas ainda apresenta uma aparência fosca em comparação ao seu brilho original. O aço eletrogalvanizado tende a ser mais brilhante e com aparência mais uniforme.

Soluções Premium em Aço Galvanizado

Em Grupo Steel ProOferecemos produtos de aço galvanizado premium, fabricados para atender aos padrões da indústria. Nossa dedicação à entrega pontual garante que seus materiais cheguem exatamente quando você precisa. Entre em contato conosco hoje mesmo para um orçamento competitivo e descubra como podemos dar suporte ao seu próximo projeto.