Содержание

Кортеновая сталь: Марки, свойства, применение и технологические процессы

- Джон

Кортеновская сталь, известная своей естественной патиной и долговечностью, сочетает в себе функциональность, эстетическую привлекательность и экологичность, что делает ее ключевым материалом в современной архитектуре и машиностроении.

В этой статье мы углубимся в суть стали Corten, изучая ее определение, свойства, марки и области применения. Мы также предлагаем обзор ее истории и методов обработки, чтобы помочь вам узнать о ней больше.

Что такое кортеновская сталь?

Сталь Corten, или атмосферостойкая сталь, — это низколегированная сталь, которая образует защитную ржавчиноподобную патину, обеспечивающую естественную коррозионную стойкость. Названная в честь «CORrosion Resistance» и «TENSile Strength», она была зарегистрирована как торговая марка US Steel в 1930-х годах. Основные стандарты включают ASTM A242 (Corten A, для архитектурного использования), ASTM A588 (Corten B, для структурного применения) и ASTM A606.

Его ключевая особенность — стабильная патина из легирующих элементов, таких как медь и хром, останавливающая дальнейшее ржавление. Прочный и визуально яркий, он широко применяется в фасадах, мостах, скульптурах и промышленных проектах.

Текстура стали Кортен

Кортеновская сталь разрабатывает грубая, органическая текстура поскольку со временем образуется ржаво-подобная патина. Поверхность сначала гладкая, но затем становится грубой и матовой по мере стабилизации защитного оксидного слоя, создавая отчетливый промышленный вид, который также предотвращает дальнейшую коррозию.

Текстура меняется в зависимости от условий окружающей среды. В циклах «влажно-сухой» патина тонкая и однородная, тогда как влажные или загрязненные области создают грубые, неровные поверхности.

Кроме того, такая обработка поверхности, как пескоструйная обработка, позволяет создать более равномерную текстуру, в то время как на необработанных поверхностях образуются естественные узоры.

Является ли кортеновская сталь дорогой?

Сталь Corten дороже мягкой стали из-за ее погодоустойчивости и долговечности. Однако ее низкие эксплуатационные расходы и длительный срок службы часто компенсируют более высокую первоначальную стоимость, особенно при использовании на открытом воздухе.

Цена также зависит от толщины, марки и поставщика: более тонкие листы, такие как ASTM A606, часто более доступны, чем конструкционные марки, такие как ASTM A588.

История Кортеновской стали

- 1930-е годы

Кортеновская сталь была разработана компанией US Steel как высокопрочный, устойчивый к коррозии материал для промышленного использования, первоначально имевший торговую марку «Corten», чтобы подчеркнуть ее коррозионная стойкость и предел прочности.

- 1940-1950-е годы

Первоначально использовался в железнодорожных вагонах и угольных хопперах из-за своей долговечности и меньших затрат на техническое обслуживание по сравнению с окрашенной сталью.

- 1960-е

Получил признание в архитектуре благодаря таким новаторским проектам, как штаб-квартира John Deere архитектора Ээро Сааринена, демонстрирующим его уникальные патину и структурные возможности.

- 1970-е

Широко применяется для строительства мостов и объектов общественной инфраструктуры, особенно в США, благодаря своей способности выдерживать атмосферные воздействия без защитного покрытия.

- 1980-е-1990-е годы

Вышел на мировые рынки, особенно в Европе и Азии, став популярным в современных архитектурных проектах благодаря своей сырой, индустриальной эстетике.

- 2000-е годы-настоящее время

Кортеновская сталь по-прежнему остается фаворитом в сфере устойчивого дизайна, ее используют при изготовлении фасадов, скульптур и ландшафтного дизайна. Она ценится за свой цвет, который со временем меняется, и за низкое воздействие на окружающую среду.

Какова марка стали Corten?

В таблице ниже приведены соответствующие марки стали Corten по стандартам ASTM, EN и GB/T, а также указанные для них категории продукции.

| Стандарт | Оценка | Категория продукта |

| ASTM A242 | Кортен А | Декоративные/неструктурные |

| ASTM A588 | Кортен Б | Конструкционные/несущие |

| ASTM А606 | А606 | Легкий архитектурный |

| EN 10025-5 | S355J0WP | Декоративные/Структурные |

| S355J2W | ||

| ГБ/Т 4171 | Q235NH | Гибкий Декоративный/Промышленный |

| Q355GNH | ||

| Q450NQR1 |

Свойства стали Corten

Химический состав кортеновской стали

| Элемент | С | Мн | Си | П | С | Cu | Кр | Ни |

| Кортен А | ≤ 0,12 | 0.20 – 0.50 | 0.25 – 0.75 | 0.07 – 0.15 | ≤ 0,03 | 0.25 – 0.55 | 0.50 – 1.25 | ≤ 0,65 |

| Кортен Б | ≤ 0,19 | 0.30 – 0.65 | 0.15 – 0.50 | ≤ 0,04 | ≤ 0,03 | 0.20 – 0.40 | 0.40 – 0.65 | ≤ 0,45 |

Физические свойства Из стали Кортен

| Свойство | Метрический | Империал |

| Плотность | ~7,85 г/см³ | ~0,284 фунта/дюйм³ |

| Температура плавления | ~1500°С | ~2732°F |

| Теплопроводность | ~40 Вт/м·К | ~23 БТЕ/ч·фут·°F |

| Тепловое расширение | ~12 x 10⁻⁶ /°C | ~6,7 x 10⁻⁶ /°F |

| Электропроводность | ~6-7% МАКС | ~6-7% МАКС |

| Магнитные свойства | Ферромагнитный | Ферромагнитный |

Механические свойства Из стали Кортен

| Свойство | Метрический | Империал |

| Предел прочности | 480–630 МПа | 69,6–91,4 тыс.фунтов на кв.дюйм |

| Предел текучести | ≥ 345 МПа | ≥ 50 тыс.фунтов на кв.дюйм |

| Твёрдость по Бринеллю (HB) | ~160–180 | ~160–180 |

| Твердость по Роквеллу (HRC) | ~10–15 | ~10–15 |

| Твёрдость по Виккерсу (HV) | ~170–190 | ~170–190 |

| Удлинение | ≥ 20% (толщина ≤ 3 мм) | ≥ 20% (толщина ≤ 0,12 дюйма) |

| Модуль упругости | ~200 ГПа | ~29 000 кфунтов на кв. дюйм |

Характеристики стали Corten

Превосходная устойчивость к атмосферным воздействиям

Кортеновская сталь содержит медь, которая помогает сформировать плотный защитный слой ржавчины, известный как медная патина. Этот слой значительно замедляет процесс окисления, обеспечивая прочный барьер против дальнейшей коррозии. Хром и никель дополнительно повышают устойчивость стали к ржавчине, делая ее более долговечной в суровых погодных условиях.

Corten также обладает способностью к самовосстановлению. Если защитная патина повреждена, воздействие воздуха и влаги позволяет стали естественным образом регенерировать медную патину, предотвращая дальнейшее ржавление и обеспечивая длительную защиту.

Низкие требования к техническому обслуживанию

Свойство самовосстановления позволяет ему восстанавливать защитный оксидный слой, предотвращая дальнейшую коррозию без необходимости частого обслуживания. В сочетании с его длительной прочностью эта способность идеально подходит для использования в сложных условиях, таких как мосты, фасады и промышленные сооружения.

Высокая прочность и долговечность

Сталь Corten обладает высокой прочностью и жесткой микроструктурой, что позволяет ей хорошо работать при циклических нагрузках (повторяющемся напряжении). Она может выдерживать большие нагрузки, противостоять усталости и износу окружающей среды, что делает ее идеальной для инфраструктуры, подверженной транспортным, ветровым и другим экологическим нагрузкам.

Как долго служит кортеновская сталь?

Кортеновская сталь прослужит более 50 лет в условиях наружного применения благодаря самовосстанавливающейся патине в зависимости от воздействия окружающей среды.

Отличительная эстетическая привлекательность

Его поверхность не только имеет уникальный эстетический вид, но и со временем приобретает устойчивость благодаря образованию защитного оксидного слоя. По мере того, как материал продолжает подвергаться атмосферным воздействиям, ржавчина стабилизируется и переходит в более равномерный глубокий красновато-коричневый или бронзовый тон. Этот фирменный вид часто желателен в архитектурных проектах, скульптурах и элементах ландшафтного дизайна.

Устойчивость и экологические преимущества

Сталь Corten является устойчивым выбором благодаря своему длительному сроку службы и пригодности к вторичной переработке. Процесс выветривания снижает потребность в покрытиях, а материал может быть переработан в конце срока службы. Это делает его вариантом с низким воздействием на окружающую среду для проектов зеленого строительства.

Каковы недостатки кортеновской стали?

Требования к комплексной обработке

Сталь Corten чувствительна к теплу из-за высокого содержания меди. В таких процессах, как сварка или резка, чрезмерное тепло может привести к разрушению слоя, богатого медью, что ставит под угрозу целостность защитной патины.

Поэтому крайне важно использовать правильные методы резки и выполнять надлежащую обработку кромок. Сварка требует предварительного нагрева и обработки после сварки, чтобы предотвратить такие проблемы, как растрескивание, и обеспечить равномерное ржавление. Кроме того, если присадочный материал, используемый при сварке, не соответствует скорости выветривания, в защитном медном слое могут образоваться зазоры.

Медленное образование патины

Сталь Corten требует времени для образования защитной медно-зеленой патины, а скорость ее образования зависит от факторов окружающей среды, таких как влажность, кислород и загрязняющие вещества. На ранних стадиях окисления патина может выглядеть неровной, обеспечивая ограниченную защиту.

В районах с низким уровнем загрязнения или недостаточной влажностью, если образование патины происходит значительно медленнее, чем ожидалось, может потребоваться срочное усиление конструкции или гальванизация.

Как сделать кортеновскую сталь ржавой?

Подвергайте кортеновскую сталь воздействию влаги и кислорода. Чтобы ускорить ржавление, опрыскайте ее водой или раствором соленой воды.

SteelPro Group предлагает варианты обработки поверхности изделий из кортеновской стали, помогающие вам быстро добиться желаемого эффекта ржавчины для ваших проектов.

Не подходит для определенных условий

Хотя кортеновская сталь отлично подходит для многих наружных применений, ее не рекомендуется использовать в следующих условиях:

- Избыточная и постоянная влажность

Сталь Corten изначально не является устойчивой к ржавчине. Постоянная влажность может помешать образованию защитной патины, что приведет к постоянной коррозии. Во влажном субтропическом климате сталь Corten может вызвать деградацию поверхности и ржавление.

- Среды с высоким содержанием соли

Соль, например, из морской воды или антиобледенительные соли, может проникать в патину, вызывая точечную коррозию и ускоренную коррозию. Морская среда или области с частым воздействием соли лучше подходят для нержавеющей стали или других коррозионно-стойких материалов.

Высокая начальная стоимость

Сталь Corten, как правило, дороже стандартной углеродистой стали из-за легирующих элементов (медь, хром, никель) и специализированного производственного процесса. Эта более высокая первоначальная стоимость может быть недостатком для проектов с ограниченным бюджетом.

Окрашивание и воздействие на окружающую среду

На ранних стадиях воздействия кортеновская сталь может проявлять кровотечение, вызывая пятна на окружающих поверхностях, таких как бетон или дерево, с ржавыми полосами. Кроме того, стоки со кортеновской стали могут вызывать окрашивание близлежащих поверхностей, особенно в районах с большим количеством осадков.

Для чего используется кортеновская сталь?

По сути, кортеновская сталь используется в проектах, где сочетание долговечности, отличительной визуальной привлекательности и низких эксплуатационных расходов является существенным. Она отлично подходит для архитектурных, структурных и художественных применений.

| Промышленность | Конкретные приложения |

| Архитектура | Фасады, облицовка, навесы, теневые конструкции и декоративные ворота. |

| Инфраструктура | Мосты, автомагистрали и конструктивные элементы подвергаются воздействию окружающей среды. |

| Искусство и скульптура | Уличные скульптуры и ландшафтное искусство. |

| Ландшафтный дизайн и городской дизайн | Подпорные стенки, элементы сада и ограждения. |

| Общественные и коммерческие помещения | Перила, вывески и элементы экстерьера в общественных местах. |

Процесс производства стали Corten

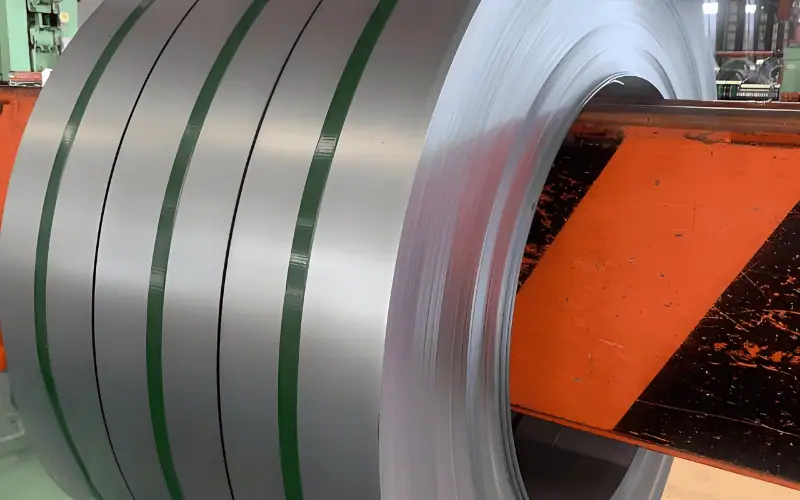

Литье и прокатка

Кортеновская сталь производится на крупных сталелитейных заводах. Сплав отливается в заготовки, которые затем подвергаются горячей прокатке в плиты, листы или рулоны в зависимости от требуемой формы.

Сварка и изготовление

Кортеновская сталь режется, сваривается и изготавливается с использованием технологий, совместимых с атмосферостойкой сталью, для сохранения ее коррозионной стойкости.

- Предварительный нагрев и послесварочная обработка необходимы для минимизации риска растрескивания стали Corten. Кроме того, использование правильного присадочного материала гарантирует, что сварные соединения сохранят состав сплава и коррозионную стойкость.

- Для резки используются такие методы, как кислородно-ацетиленовая резка, плазменная резка и лазерная резка, с последующей обработкой кромок для обеспечения гладкости поверхностей, способствующей равномерному образованию защитной патины.

Формирование патины

Воздействие влаги и кислорода вызывает образование защитного красновато-коричневого оксидного слоя, который предотвращает дальнейшую коррозию.

Для ускорения процесса ржавления можно использовать такие виды обработки поверхности, как кислотные промывки, распыление соленой воды или камеры влажности. Эти методы могут помочь достичь полной патины за более короткий период.

Обработка поверхности и осмотр

После формирования патины проводится окончательная проверка, и могут быть нанесены дополнительные защитные покрытия для повышения долговечности в суровых условиях.

Доставка и установка

Сталь доставляется, устанавливается и продолжает покрываться патиной, обеспечивая долговечный и визуально уникальный внешний вид.

Нужна кортеновская сталь для вашего следующего проекта?

SteelPro Group предлагает продукцию из кортеновской стали, такую как ASTM A242, ASTM A588, и ASTM A606. Наш ассортимент включает в себя листы, рулоны, уголки, балки и многое другое из атмосферостойкой стали. Мы также можем предложить индивидуальные услуги, такие как:

- Ускоренная патинированная обработка или предварительно ржавая кортеновская сталь

- Индивидуальная резка и размер

- Доставка JIT (точно вовремя)

- Доставка по всему миру

Как опытный поставщик стали Corten, SteelPro Group гарантирует, что получаемая вами продукция имеет стабильное качество и минимальные допуски. Если у вас есть какие-либо требования или вопросы, не стесняйтесь обращаться к нам за предложением или для обсуждения ваших решений!