A242 | Стойкая к атмосферным воздействиям сталь

A242 | Стойкая к атмосферным воздействиям сталь

A242 Weathering Steel — это высокопрочная низколегированная сталь, предназначенная для сопротивления атмосферной коррозии. «A242» относится к ее стандарту ASTM. Она образует защитный слой ржавчины при воздействии стихии, что снижает необходимость в покраске. A242 обеспечивает долговечность, прочность, свариваемость и используется в мостах, зданиях и наружных конструкциях. Эквивалентные марки включают E36WA4, S355J2WP и A588.

Описание

Что такое A242?

А242 — низколегированная сталь, содержащая 0,25–0,551ТП3Т меди и 0,20–0,501ТП3Т хрома. Он поставляется в виде цельных пластин или секций и устойчив к коррозии. При контакте с воздухом образует защитный слой оксида железа, что снижает необходимость в покраске. Его обрабатывают методом горячей прокатки и используют в наружных конструкциях, таких как мосты и здания.Почему стоит выбрать погодоустойчивую сталь A242?

Спецификация продукта

| Категория | Подробности |

| Стандарт качества | ASTM A242/A242M |

| Сертификаты | ASTM G101, ISO 9001, EN 10025 S355J2WP, BV, SGS |

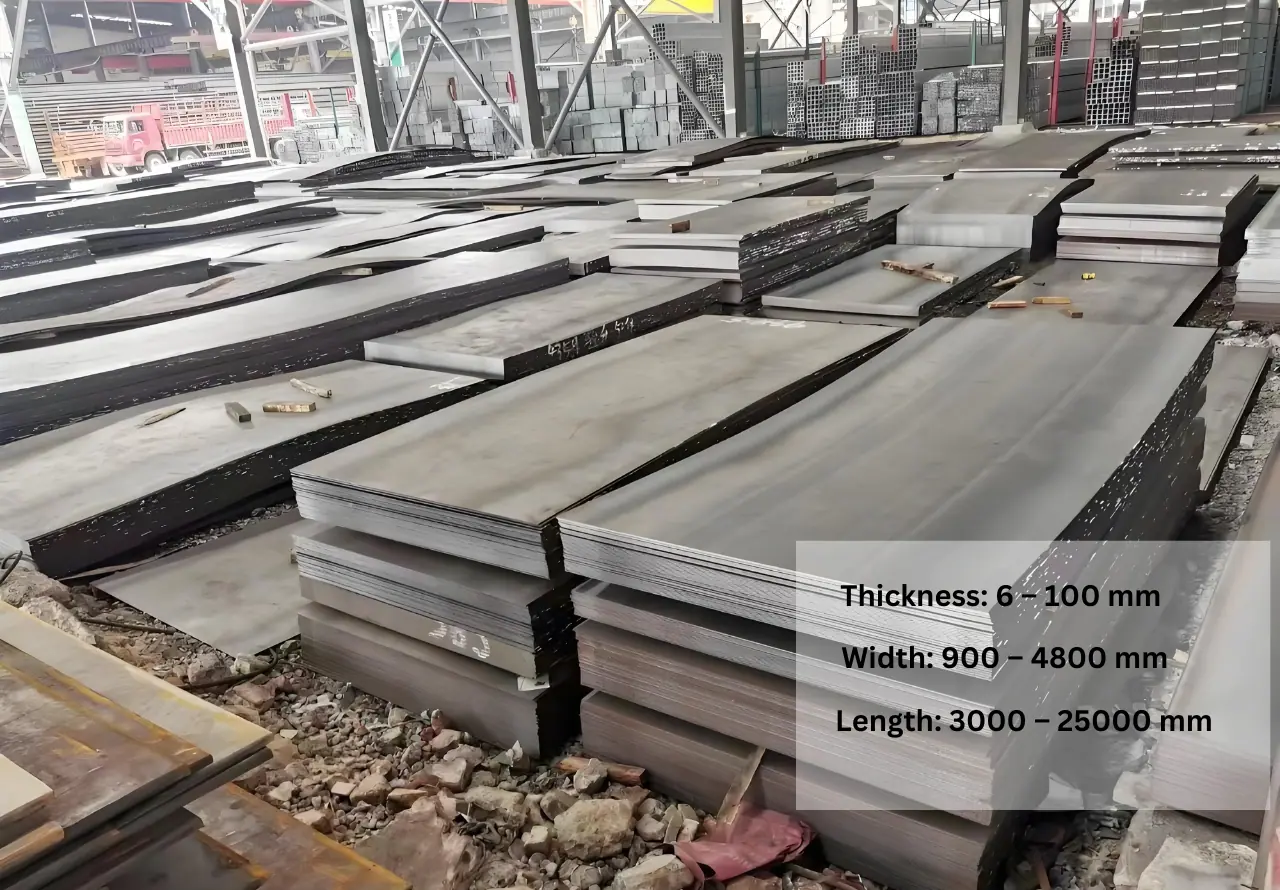

| Толщина | 6-100мм |

| Ширина | 900-4800мм |

| Длина | 3000-25000мм |

| Масса | Зависит от длины и ширины |

| Наружный диаметр (НД) | Трубы: от 60 мм до 100 мм, прутки: от 10 мм до 150 мм |

| Внутренний диаметр (ВД) | Трубы: от 5 мм до 15 мм |

| Допуски | Толщина: от ±0,25 мм до ±1,0 мм, Ширина: от ±2 мм до ±4 мм, Длина: от ±5 мм до ±10 мм |

| Технологии | Горячая прокатка |

| Служба обработки | Сварка, штамповка, резка, гибка, размотка |

| Формы | Стальная пластина для атмосферных воздействий, Стальной лист для атмосферных воздействий, Трубы, Профили |

| MOQ (минимальный объем заказа) | 5 тонн (по фактическому тоннажу) |

| Время выполнения | Обычно 7-20 дней (чем больше заказанный тоннаж, тем дольше срок поставки) |

| Условия цены и оплаты | На основе требований заказчика, T/T, L/C |

| Порты | Циндао, Ляньюньган, Далянь |

| Страны экспорта | Юго-Восточная Азия, Центральная Азия, Европа, Россия, Южная Америка, Ближний Восток и т. д. |

| Способ доставки | Предлагает морские, воздушные и индивидуальные перевозки |

Химический состав

| Элемент | Содержимое A242 Тип 1 (%) | Содержимое A242 Тип 2 (%) |

|---|---|---|

| Углерод, С | ≤ 0,15 | ≤ 0,15 |

| Хром, Cr | 0.40 – 0.65 | 0.40 – 0.70 |

| Медь, Cu | 0.20 – 0.40 | 0.30 – 0.50 |

| Марганец, Mn | 0.20 – 0.50 | 0.20 – 0.60 |

| Никель, Ni | ≤ 0,20 | ≤ 0,20 |

| Фосфор, P | 0.07 – 0.15 | 0.08 – 0.15 |

| Кремний, Si | 0.15 – 0.30 | 0.15 – 0.30 |

| Сера, S | ≤ 0,05 | ≤ 0,05 |

Механические свойства

| Свойство | Тип 1 (≤ 16 мм) | Тип 1 (> 16 мм) | Тип 2 (≤ 16 мм) | Тип 2 (> 16 мм) |

|---|---|---|---|---|

| Предел прочности | 480 МПа (70 тыс.фунтов/кв.дюйм) | 460 МПа (67 тыс.фунтов/кв.дюйм) | 480 МПа (70 тыс.фунтов/кв.дюйм) | 460 МПа (67 тыс.фунтов/кв.дюйм) |

| Предел текучести | 345 МПа (50 тыс.фунтов/кв.дюйм) | 315 МПа (46 тыс.фунтов/кв.дюйм) | 345 МПа (50 тыс.фунтов/кв.дюйм) | 315 МПа (46 тыс.фунтов/кв.дюйм) |

| Удлинение (2 дюйма / 50 мм) | 21% | 18% | 21% | 18% |

| Твердость по Бринеллю | 170-190 НВ | 170-190 НВ | 170-190 НВ | 170-190 НВ |

| Твердость по Роквеллу | 84-92 HRБ | 84-92 HRБ | 84-92 HRБ | 84-92 HRБ |

| Твердость по Виккерсу | 175-200 ВН | 175-200 ВН | 175-200 ВН | 175-200 ВН |

| Модуль упругости | 190-210 ГПа | 190-210 ГПа | 190-210 ГПа | 190-210 ГПа |

Данные после нормализующей обработки

| Свойство | Тип 1 (≤ 16 мм) (нормализованный) | Тип 1 (> 16 мм) (нормализованный) | Тип 2 (≤ 16 мм) (нормализованный) | Тип 2 (> 16 мм) (нормализованный) |

|---|---|---|---|---|

| Предел прочности | 500 МПа (72 тыс.фунтов на кв. дюйм) | 480 МПа (70 тыс.фунтов/кв.дюйм) | 500 МПа (72 тыс.фунтов на кв. дюйм) | 480 МПа (70 тыс.фунтов/кв.дюйм) |

| Предел текучести | 365 МПа (53 тыс.фунтов/кв.дюйм) | 335 МПа (49 тыс.фунтов/кв.дюйм) | 365 МПа (53 тыс.фунтов/кв.дюйм) | 335 МПа (49 тыс.фунтов/кв.дюйм) |

| Удлинение (2 дюйма / 50 мм) | 20% | 18% | 20% | 18% |

| Твердость по Бринеллю | 185-200 НВ | 185-200 НВ | 185-200 НВ | 185-200 НВ |

| Твердость по Роквеллу | 88-95 HRБ | 88-95 HRБ | 88-95 HRБ | 88-95 HRБ |

| Твердость по Виккерсу | 190-210 ВН | 190-210 ВН | 190-210 ВН | 190-210 ВН |

| Модуль упругости | 200 ГПа | 200 ГПа | 200 ГПа | 200 ГПа |

Отрасли и приложения

| Отрасли промышленности | Продукция |

|---|---|

| Мосты и инфраструктура | Мостовой настил, опорные балки, ограждения, фермы, пешеходные дорожки |

| Фасады зданий | Наружные стеновые панели, облицовка, оконные рамы, кровля, декоративные фасады |

| Железная дорога и транспорт | Железнодорожные вагоны, борта контейнеров, транспортные рамы, корпуса сцепок, настилы платформ |

| Энергия и мощность | Опоры линий электропередач, конструкции ветровых турбин, корпуса трансформаторов, градирни, корпуса оборудования |

| Морские и прибрежные | Доковые конструкции, морские сваи, береговые заграждения, портовые краны, переборки |

| Сельскохозяйственное оборудование | Зерновые бункеры, резервуары для хранения, каркасы оборудования, ограждения, панели оборудования |

| Промышленное оборудование | Конвейерные рамы, технологические емкости, защитные кожухи, вентиляционные системы, погрузочные платформы |

| Скульптуры и искусство | Памятники, скульптуры на открытом воздухе, художественные инсталляции, большие статуи, архитектурные сооружения |

| Безопасность на шоссе | Ограждения, разделительные барьеры, дорожные знаки, сигнальные столбы, защитные ограждения |

Упаковка

SteelPRO Group гарантирует, что атмосферостойкая сталь A242 будет профессионально упакована для безопасной транспортировки и обработки. Наш метод решает основные проблемы при упаковке стали A242:

- Защитное покрытие: Для предотвращения коррозии во время транспортировки наносится атмосферостойкий слой, особенно при морских перевозках, где контроль влажности имеет решающее значение.

- Надежная обвязка и крепление: Для фиксации материалов мы используем прочные стальные или полиэстеровые ленты, что снижает риск смещения или повреждения даже при дальних перевозках.

- Контроль влажности и упаковка: Каждая партия упакована во влагостойкую упаковку, защищающую сталь от прямого воздействия воды, что необходимо для сохранения целостности антикоррозионного слоя.

- Индивидуальное паллетирование: Наши команды по упаковке создают индивидуальные поддоны и опоры для различных стальных профилей, от пластин до прутков, обеспечивая устойчивость и легкую разгрузку в местах назначения.

Процесс упаковки SteelPRO Group гарантирует, что наша атмосферостойкая сталь марки A242 поступает в оптимальном состоянии, готовая к немедленному использованию.

Обработка

Варианты термообработки A242

Мы поставляем атмосферостойкую сталь марки A242 в различных термообработанных формах для удовлетворения различных потребностей в области применения:

- Нормализованный A242: Доступен в виде пластин и прутков, нормализованных при температуре 900°C для повышения прочности и однородности, идеально подходит для использования в конструкциях.

- Отожженный А242: Предлагается в листах и секциях, отожженных при температуре 700–750 °C для улучшения формуемости, подходит для индивидуального применения.

- Закаленная А242: поставляется в рулонах и полосах, закаляется при температуре 200–600 °C для дополнительной устойчивости, используется в ударопрочных деталях.

- Горячекатаный А242: Доступен в виде пластин, прутков и труб в необработанном виде, подходит для общих применений в условиях атмосферных воздействий.

- Варианты поверхности: обработанные и предварительно ржавые поверхности отвечают эстетическим запросам, широко используются в архитектурном дизайне.

A242 Отделка поверхности

Для оптимизации производительности мы предлагаем ряд вариантов отделки поверхности, специально разработанных для применения в атмосферостойкой стали марки A242:

- Дробеструйная обработка: Обеспечивает чистую, шероховатую поверхность для улучшения адгезии покрытий или краски.

- Маринование: Удаляет окалину и загрязнения, образуя гладкую, однородную поверхность, идеальную для дальнейшей обработки.

- Покрытие маслом: Добавляет тонкий слой защитного масла, уменьшая окисление во время хранения и транспортировки.

- Покрытие, препятствующее появлению отпечатков пальцев: Добавляет прозрачный защитный слой для уменьшения размазывания и появления поверхностных следов, обычно используется в видимых областях применения.

- Пассивация: Повышает коррозионную стойкость за счет образования защитного оксидного слоя, идеально подходит для длительного использования на открытом воздухе.

- Фосфатирование: Создает устойчивый к коррозии базовый слой, улучшающий адгезию краски, широко используемый в строительстве и автомобильных деталях.

По запросу могут быть выполнены индивидуальные требования к обработке поверхности.

Поставщик атмосферостойкой стали A242

Являясь надежным поставщиком атмосферостойкой стали марки A242, мы предлагаем комплексную поддержку по вопросам цен, ассортимента продукции, качества и логистики для удовлетворения потребностей вашего проекта:

- Конкурентные цены и ориентация на клиента: Мы предлагаем справедливые цены и гарантируем оперативную поддержку на протяжении всего проекта, помогая вам добиться экономической эффективности без ущерба для качества.

- Полный ассортимент продукции с точными опциями: Наш ассортимент атмосферостойкой стали A242 включает пластины, прутки, рулоны и листы с возможностью индивидуальной резки, гибки и формовки для точного соответствия спецификациям.

- Строгий контроль качества и сертификация: Каждая партия проходит строгие испытания, и мы обеспечиваем сертификацию в соответствии со стандартами ASTM и EN, гарантируя долговечность и соответствие отраслевым требованиям.

- Индивидуальные решения, безопасная упаковка и надежная логистика: Мы поставляем индивидуальные решения A242 с безопасной упаковкой, которая предотвращает повреждения при транспортировке, и обеспечиваем эффективную логистику, информируя вас на каждом этапе доставки.

Благодаря нашему опыту и приверженности качеству мы готовы оказать поддержку как небольшим, так и крупным проектам с использованием атмосферостойкой стали марки A242.

Наши услуги

SteelPRO Group – производитель и поставщик решений для специальной стали, предлагающий многоотраслевые прикладные решения и индивидуальные услуги, качество 100% бесплатно, сопровождающий клиентов в их росте!

Наш контроль качества

- Округлость

- Терпимость

- Микроструктура

- Неразрушающий контроль

- Разрушающий контроль

- Управление процессами

Обработка интеграции услуг

- Сварка

- Изготовление Металла

- Обработка на станках с ЧПУ

- Токарный станок

- Формирование

Какова максимальная толщина для атмосферостойкой стали A242?

Максимальная толщина для A242 может варьироваться в зависимости от поставщика и оборудования, но мы обычно предлагаем до 100 мм. Конкретные требования могут быть выполнены на заказ.

Какова цена на A242 по сравнению с другими атмосферостойкими сталями?

Благодаря своему составу и масштабам производства марка A242 имеет конкурентоспособную цену по сравнению с другими высокоэффективными атмосферостойкими сталями, что обеспечивает экономическую эффективность для крупных проектов.

Требует ли A242 особого обращения при хранении?

Да, для сохранения свойств выветривания A242 следует хранить в сухом месте. Мы рекомендуем использовать защитную упаковку, если необходимо длительное хранение.

Можно ли скорректировать заказы в процессе производства, если изменятся спецификации?

Да, мы предлагаем гибкие решения. Если корректировки незначительны, мы обычно можем включить их в середине производства; существенные изменения могут потребовать дополнительного времени на подготовку.

Какова ожидаемая долговечность в прибрежных или высоковлажных условиях?

A242 хорошо себя зарекомендовал в коррозионных средах, однако в зонах с высокой влажностью для максимального увеличения срока службы его лучше предварительно протравить или загерметизировать.

Предоставляются ли по запросу документация и производственные записи?

Да, мы предоставляем полную документацию, включая производственные записи и отчеты о проверке качества, для обеспечения прослеживаемости и соответствия.

КОНТАКТ

КОНТАКТ

Сертификаты

Другие продукты

-

-

Группа компаний SteelPRO предлагает листы из высокопрочной конструкционной стали FH550 для судостроения....

-

Группа компаний SteelPRO предлагает на складе листовую судостроительную сталь высокой прочности DH550....

-

SteelPro Group предлагает высокопрочную сталь FH36 для судостроения. Она имеет...