A841 | Легированная сталь для сосудов под давлением

A841 | Легированная сталь для сосудов под давлением

A841 — это сосуд под давлением из легированной стали и котлы, известные своей высокой прочностью и жесткостью. «A» обозначает железный материал, а «841» относится к стандарту ASTM для термомеханически обработанных пластин. Ее также называют сталью TMCP, она обладает превосходной свариваемостью, ударной вязкостью и стойкостью к разрушению. Используется в оборудовании и резервуарах высокого давления. Похожие марки включают P500Q, P690Q.

Описание

Что такое A841?

A841 — это стальной сплав с 1,25% хрома и 0,5% молибдена, предназначенный для сосудов под давлением. Он подвергается термомеханической обработке (TMCP) для повышения ударной вязкости и прочности. A841 обеспечивает отличную свариваемость, ударопрочность и вязкость разрушения, идеально подходит для использования под высоким давлением в нефтяной, газовой, химической и энергетической промышленности. Он выпускается в семи классах: A, B, C, D, E, F, G, с классификациями, такими как класс 1 и класс 2, основанными на прочности на растяжение и термической обработке, а также другими классификациями.Почему стоит выбрать легированную сталь A841 для сосудов высокого давления?

Для сред с высоким давлением, Сталь для сосудов под давлением A841 — лучший выбор. Мы рекомендуем A841 за его прочность, свариваемость и ударопрочность. Его термомеханическая обработка обеспечивает превосходную производительность в сложных условиях, идеально подходит для таких отраслей, как нефть, газ и энергетика. Выбор A841 означает долгосрочную безопасность и надежность. A841 выделяется среди других сталей, предлагая постоянную производительность под нагрузкой и меньше проблем со сваркой. Его превосходная вязкость разрушения и адаптивность делают его идеальным для критически важных применений. Если вам нужны альтернативы, мы также предлагаем А387 и А516, которые обеспечивают аналогичные возможности высокого давления, подходящие для вашего проекта.Спецификация продукта

| Категория | Подробности |

| Стандарт качества | ASTM A841/A841M |

| Сертификаты | ISO 9001, CE, БПВХ, EN 10028, ISO 14001, ISO 15156. |

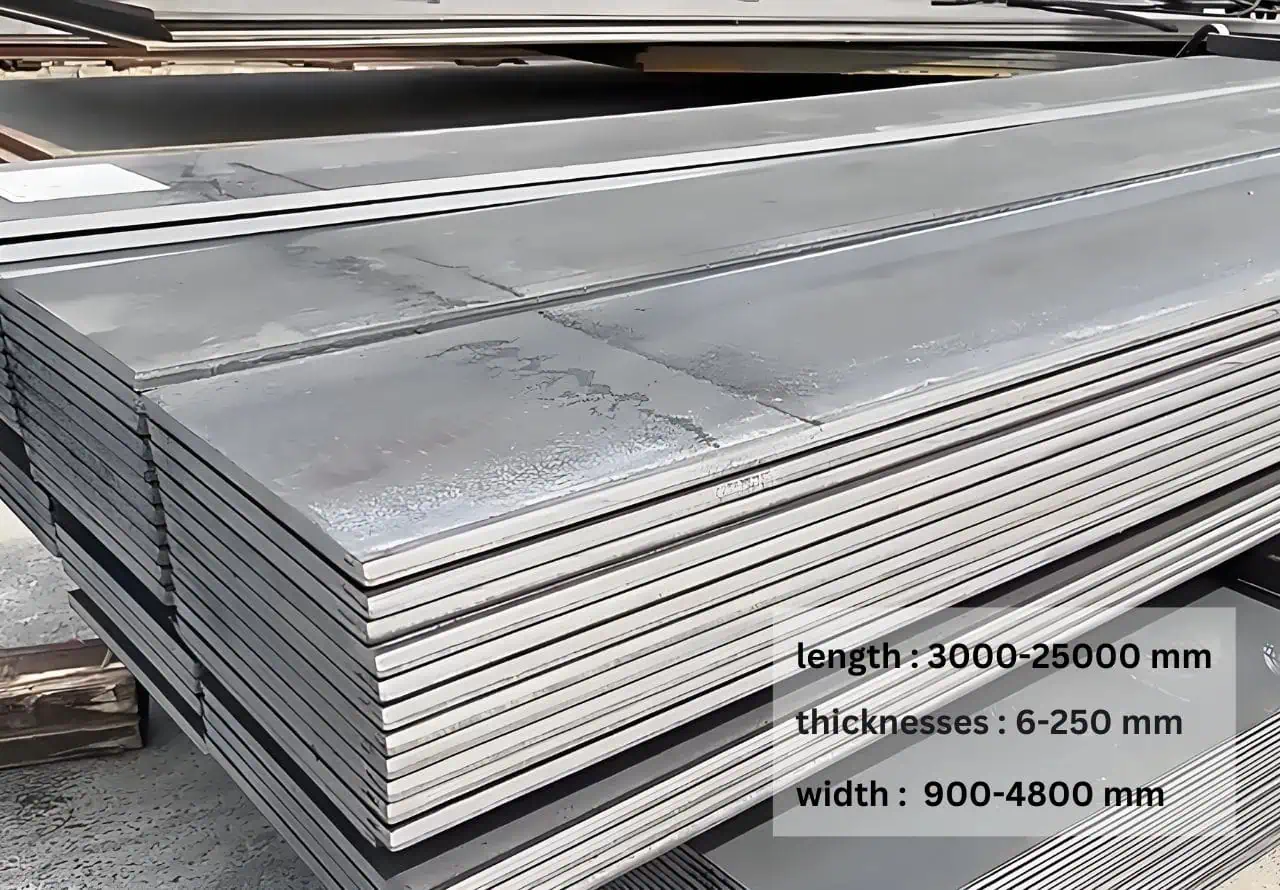

| Толщина | 8-100мм |

| Ширина | 900-4800мм |

| Длина | 3000-25000мм |

| Масса | Зависит от длины и ширины |

| Наружный диаметр (НД) | Трубы: от 20 мм до 610 мм, Прутки: от 10 мм до 400 мм |

| Внутренний диаметр (ВД) | Трубы: от 15 мм до 600 мм |

| Допуски | Толщина: от ±0,3 мм до ±1,2 мм, ширина: от ±3 мм до ±10 мм, длина: от ±5 мм до ±15 мм |

| Технологии | Горячая прокатка, ТМКП |

| Служба обработки | Гибка, сварка, размотка, резка, штамповка |

| Формы | Стальная пластина для сосудов под давлением, стальной лист для сосудов под давлением, трубы, профили |

| MOQ (минимальный объем заказа) | 5 тонн (по фактическому тоннажу) |

| Время выполнения | Обычно 7-20 дней |

| Условия цены и оплаты | На основе требований заказчика, T/T, L/C |

| Порты | Циндао, Ляньюньган, Далянь |

| Страны экспорта | Юго-Восточная Азия, Центральная Азия, Европа, Россия, Южная Америка, Ближний Восток и т. д. |

| Способ доставки | Предлагает морские, воздушные и индивидуальные перевозки |

Химический состав

| Элемент | Класс А (Класс 1) | Класс B (класс 1) | Класс C (Класс 1) | Класс D (класс 3) | Класс E (Класс 4) | Класс F (класс 6) | Класс G (10 класс) |

|---|---|---|---|---|---|---|---|

| Углерод, С | 0,2 макс. | 0,15 макс. | 0,1 макс. | 0,09 макс. | 0,07 макс. | 0,1 макс. | 0,13 макс. |

| Кремний, Si | 0.15 – 0.5 | 0.15 – 0.5 | 0.15 – 0.5 | 0.05 – 0.25 | 0.05 – 0.3 | 0.1 – 0.45 | 0.04 – 0.15 |

| Марганец, Mn | 0.7 – 1.35 | 0.7 – 1.35 | 0.7 – 1.6 | 1 – 2 | 0.7 – 1.6 | 1.1 – 1.7 | 0.6 – 1.2 |

| Фосфор, P | 0,03 макс. | 0,03 макс. | 0,03 макс. | 0,01 макс. | 0,015 макс. | 0,02 макс. | 0,015 макс. |

| Сера, S | 0,03 макс. | 0,025 макс. | 0,015 макс. | 0,005 макс. | 0,005 макс. | 0,008 макс. | 0,015 макс. |

| Хром, Cr | 0,25 макс. | 0,25 макс. | 0,25 макс. | 0,3 макс. | 0,3 макс. | 0,3 макс. | 1 макс. |

| Никель, Ni | 0,25 макс. | 0,6 макс. | 0,25 макс. | 1 – 5 | 0,6 макс. | 0,85 макс. | 6 – 7.5 |

| Медь, Cu | 0,35 макс. | 0,35 макс. | 0,35 макс. | 0,5 макс. | 0,35 макс. | 0,4 макс. | 0,35 макс. |

| Молибден, Mo | 0,08 макс. | 0,3 макс. | 0,08 макс. | 0,4 макс. | 0,3 макс. | 0,5 макс. | 0,3 макс. |

| Ванадий, V | 0,06 макс. | 0,06 макс. | 0,06 макс. | 0,02 макс. | 0,06 макс. | 0,09 макс. | 0,02 макс. |

| Ниобий, Nb | 0,03 макс. | 0,03 макс. | 0,06 макс. | 0,05 макс. | 0,08 макс. | 0,1 макс. | 0,05 макс. |

| Титан, Ti | – | – | 0,02 макс. | 0,03 макс. | – | – | 0,02 макс. |

| Бор, Б | – | – | – | 0.0005 – 0.002 | 0,0007 макс. | 0,0007 макс. | 0.0005 – 0.002 |

| Алюминий, Al | Al≥0,02 или Als≥0,015 | Al≥0,02 или Als≥0,015 | Al≥0,02 или Als≥0,015 | 0,02 мин. | Al≥0,02 или Als≥0,015 | Al≥0,02 или Als≥0,015 | 0,008 мин. |

Механические свойства

| Свойство | Класс А (Класс 1) | Класс B (класс 1) | Класс C (Класс 1) | Класс D (класс 3) | Класс E (Класс 4) | Класс F (класс 6) | Класс G (10 класс) |

|---|---|---|---|---|---|---|---|

| Предел прочности | 585 – 760 МПа | 85–110 фунтов на квадратный дюйм | 585 – 760 МПа | 85–110 фунтов на квадратный дюйм | 620 – 790 МПа | 90–115 фунтов на квадратный дюйм | 690 – 830 МПа | 100–120 фунтов на квадратный дюйм | 620 – 790 МПа | 90–115 фунтов на квадратный дюйм | 620 – 760 МПа | 90–110 фунтов на квадратный дюйм | 690 – 930 МПа | 100–135 фунтов на квадратный дюйм |

| Предел текучести | 485 МПа | 70 тыс.фунтов на кв.дюйм | 485 МПа | 70 тыс.фунтов на кв.дюйм | 515 МПа | 75 тыс.фунтов на кв.дюйм | 585 МПа | 85 тыс.фунтов на кв.дюйм | 515 МПа | 75 тыс.фунтов на кв.дюйм | 515 МПа | 75 тыс.фунтов на кв.дюйм | 620 МПа | 90 тыс.фунтов на кв.дюйм |

| Твёрдость по Бринеллю (HB) | 170 – 220 НВ | 170 – 220 НВ | 180 – 230 НВ | 200 – 250 НВ | 180 – 230 НВ | 180 – 230 НВ | 200 – 260 НВ |

| Твердость по Роквеллу (HRC) | 82 – 90 HRB | 82 – 90 HRB | 83 – 92 HRБ | 87 – 95 HRБ | 83 – 92 HRБ | 83 – 92 HRБ | 87 – 96 HRБ |

| Твёрдость по Виккерсу (HV) | 170 – 220 В | 170 – 220 В | 180 – 230 В | 200 – 250 ВН | 180 – 230 В | 180 – 230 В | 200 – 260 ВН |

| Удлинение (% в 50 мм) | 18% | 18% | 16% | 15% | 16% | 16% | 14% |

| Модуль упругости | 200 ГПа | 29 000 кфунтов на кв. дюйм | 200 ГПа | 29 000 кфунтов на кв. дюйм | 200 ГПа | 29 000 кфунтов на кв. дюйм | 200 ГПа | 29 000 кфунтов на кв. дюйм | 200 ГПа | 29 000 кфунтов на кв. дюйм | 200 ГПа | 29 000 кфунтов на кв. дюйм | 200 ГПа | 29 000 кфунтов на кв. дюйм |

Данные после нормализующей обработки

| Свойство | Класс А (Класс 1) | Класс B (класс 1) | Класс C (Класс 1) | Класс D (класс 3) | Класс E (Класс 4) | Класс F (класс 6) | Класс G (10 класс) |

|---|---|---|---|---|---|---|---|

| Предел прочности | 690 – 830 МПа | 100–120 фунтов на квадратный дюйм | 690 – 830 МПа | 100–120 фунтов на квадратный дюйм | 760 – 900 МПа | 110–130 фунтов на квадратный дюйм | 830 – 930 МПа | 120–135 фунтов на квадратный дюйм | 760 – 900 МПа | 110–130 фунтов на квадратный дюйм | 690 – 860 МПа | 100–125 фунтов на квадратный дюйм | 830 – 960 МПа | 120–140 фунтов на квадратный дюйм |

| Предел текучести | 585 МПа | 85 тыс.фунтов на кв.дюйм | 585 МПа | 85 тыс.фунтов на кв.дюйм | 620 МПа | 90 тыс.фунтов на кв.дюйм | 690 МПа | 100 тыс.фунтов на кв.дюйм | 620 МПа | 90 тыс.фунтов на кв.дюйм | 620 МПа | 90 тыс.фунтов на кв.дюйм | 690 МПа | 100 тыс.фунтов на кв.дюйм |

| Твёрдость по Бринеллю (HB) | 200 – 250 НВ | 200 – 250 НВ | 210 – 270 НВ | 230 – 280 НВ | 210 – 270 НВ | 200 – 260 НВ | 230 – 300 НВ |

| Твердость по Роквеллу (HRC) | 87 – 95 HRБ | 87 – 95 HRБ | 88 – 96 HRБ | 90 – 98 HRБ | 88 – 96 HRБ | 87 – 96 HRБ | 90 – 99 HRБ |

| Твёрдость по Виккерсу (HV) | 200 – 250 ВН | 200 – 250 ВН | 210 – 270 В | 230 – 280 В | 210 – 270 В | 200 – 260 ВН | 230 – 300 В |

| Удлинение (% в 50 мм) | 15% | 15% | 14% | 13% | 14% | 14% | 12% |

| Модуль упругости | 200 ГПа | 29 000 кфунтов на кв. дюйм | 200 ГПа | 29 000 кфунтов на кв. дюйм | 200 ГПа | 29 000 кфунтов на кв. дюйм | 200 ГПа | 29 000 кфунтов на кв. дюйм | 200 ГПа | 29 000 кфунтов на кв. дюйм | 200 ГПа | 29 000 кфунтов на кв. дюйм | 200 ГПа | 29 000 кфунтов на кв. дюйм |

Отрасли и приложения

| Отрасли промышленности | Продукция |

|---|---|

| Сосуды под давлением | Химические реакторы, Газовые резервуары, Котельные барабаны, Теплообменники, Резервуары для хранения сжиженного нефтяного газа |

| Судостроение | Корпусные конструкции, Переборки, Палубные конструкции, Морские платформы, Корпуса подводных лодок |

| Нефть и газ | Резервуары для хранения, Нефтяные платформы, Трубопроводные системы, Буровое оборудование, Напорные клапаны |

| Атомные электростанции | Корпуса реакторов, Защитные сосуды, Парогенераторы, Контейнеры для ядерных отходов, Теплообменники |

| Нефтехимическая промышленность | Технологические сосуды, дистилляционные башни, теплообменники, резервуары для хранения химикатов, газоочистители |

| Строительство | Конструкционные балки, Стальные мосты, Сверхпрочные колонны, Фундаментные опоры, Сооружения для ветроэнергетики в открытом море |

| Горнодобывающее оборудование | Стрелы экскаваторов, Кузова карьерных самосвалов, Дробилки, Лопаты, Погрузчики |

| Аэрокосмическая промышленность | Фюзеляж самолета, Конструкционные детали космического корабля, Баки ракеты-носителя, Напорные баки, Компоненты двигателя |

| Военный | Бронетехника, Ракетные шахты, Прочные корпуса подводных лодок, Башни танков, Контейнеры для хранения боеприпасов |

Упаковка

Вот четыре основных преимущества SteelPRO Group при упаковке стали марки А841:

- Индивидуальная упаковка: Мы изготавливаем упаковку под заказ для A841, гарантируя надлежащую посадку и защиту для изделий разных размеров и толщины.

- Защита от коррозии: Мы используем влагостойкие покрытия и ингибиторы коррозии для защиты стали марки A841 от повреждений.

- Усиленная обвязка: Надежные методы крепления обеспечивают устойчивость A841 во время транспортировки, предотвращая перемещение и повреждение.

- Соответствие стандартам: Мы соблюдаем международные стандарты упаковки, обеспечивая безопасную и соответствующую требованиям транспортировку стали марки A841.

Группа компаний SteelPRO обеспечивает надежную и качественную упаковку для стали марки А841.

Обработка

Варианты термообработки A841

Мы предлагаем следующие термообработанные легированные стали марки А841 для сосудов под давлением:

- Закаленная и отпущенная сталь A841: Обрабатывается при температуре 900–1150 °C, обеспечивая высокую прочность и ударную вязкость для сложных условий эксплуатации.

- Нормализованная сталь А841: Обработан при температуре 870-950°C, обеспечивает повышенную пластичность и хорошую свариваемость.

- Сталь ТМКП А841: Улучшенная прочность и свариваемость за счет термомеханической обработки.

- Сталь A841 со снятым напряжением: Нагревается при температуре 540-600°C для снижения остаточных напряжений после сварки или формовки.

- Пользовательские параметры: Мы также поставляем сталь марки A841 в прокатном виде или по индивидуальному заказу в соответствии с вашими потребностями.

Наша сталь A841 обеспечивает оптимальные механические свойства для различных областей применения.

A841 Отделка поверхности

Мы предлагаем следующие виды обработки поверхности стали А841:

- Дробеструйная обработка: Удаляет ржавчину, окалину и загрязнения, обеспечивая чистую поверхность для дальнейшей обработки.

- Маринование: Удаляет оксиды и загрязнения, повышая коррозионную стойкость и подготавливая поверхность к нанесению покрытия.

- Цинкование: Наносит защитное цинковое покрытие, предотвращающее коррозию и продлевающее срок службы стали.

- Рисование: Добавляет защитный слой для предотвращения коррозии и улучшения эстетического вида, доступен в различных вариантах покрытия.

- Антикоррозийное покрытие: Создает специальный слой, защищающий от суровых условий окружающей среды и воздействия химических веществ.

По запросу могут быть выполнены индивидуальные требования к обработке поверхности.

Поставщик стали для сосудов высокого давления A841

Являясь надежным поставщиком легированной стали марки A841 для сосудов высокого давления, мы предоставляем ведущие в отрасли услуги и экспертные знания по многим аспектам:

Конкурентоспособные цены: Мы предлагаем высококонкурентные цены без ущерба качеству, гарантируя ценность ваших инвестиций.

Своевременная доставка: Наше эффективное производство и логистика гарантируют быстрые сроки выполнения заказов, позволяя вашим проектам соблюдать график.

Полный ассортимент продукции: Мы поставляем полный ассортимент марок A841 для удовлетворения различных потребностей в области применения, с различной толщиной и размерами.

Строгий контроль качества и сертификация: Каждая партия стали марки A841 проходит строгие испытания качества, и мы предоставляем сертификаты в соответствии с международными стандартами, такими как EN 10204 3.1/3.2.

Индивидуальные решения: Мы поставляем индивидуальные решения, основанные на требованиях вашего проекта, включая индивидуальные размеры, формы и обработку поверхности.

Безопасная упаковка и эффективная логистика: Мы обеспечиваем надежную, неповрежденную упаковку для всех изделий из стали марки A841 и обеспечиваем надежную, прозрачную логистику, гарантируя бесперебойную доставку.

С нами вы получите профессиональное комплексное решение для всех ваших потребностей в сосудах под давлением из легированной стали марки A841.

Наши услуги

SteelPRO Group – производитель и поставщик решений для специальной стали, предлагающий многоотраслевые прикладные решения и индивидуальные услуги, качество 100% бесплатно, сопровождающий клиентов в их росте!

Наш контроль качества

- Округлость

- Терпимость

- Микроструктура

- Неразрушающий контроль

- Разрушающий контроль

- Управление процессами

Обработка интеграции услуг

- Сварка

- Изготовление Металла

- Обработка на станках с ЧПУ

- Токарный станок

- Формирование

В чем разница между классом 1 и классом 2 для стали A841?

Классы 1 и 2 различаются в основном по термической обработке и механическим свойствам, при этом класс 2 обеспечивает более высокую прочность для более сложных условий применения.

Можно ли использовать сплав A841 в условиях высокого давления?

Да, A841 предназначен для сред с высоким давлением, обычно используется в сосудах под давлением и резервуарах для хранения.

Обеспечивает ли сталь A841 хорошую свариваемость?

Да, сталь А841 обладает хорошей свариваемостью, особенно после термической обработки, такой как нормализация или отпуск.

Предоставляете ли вы поддержку с техническими спецификациями и чертежами?

Да, мы оказываем полную поддержку по техническим спецификациям, включая индивидуальные решения на основе чертежей и потребностей вашего проекта.

Можете ли вы выполнить срочные запросы?

Да, мы тесно сотрудничаем с клиентами для обработки срочных запросов и ускорения выполнения заказов при необходимости, в зависимости от наличия товара на складе и требований к обработке.

Какие испытания проводятся перед отправкой?

Мы проводим тщательные испытания, включая проверку механических и химических свойств, чтобы гарантировать соответствие всей продукции отраслевым стандартам перед отправкой.

КОНТАКТ

КОНТАКТ

Сертификаты

Другие продукты

-

-

Группа компаний SteelPRO предлагает листы из высокопрочной конструкционной стали FH550 для судостроения....

-

Группа компаний SteelPRO предлагает на складе листовую судостроительную сталь высокой прочности DH550....

-

SteelPro Group предлагает высокопрочную сталь FH36 для судостроения. Она имеет...