13CrMo4-5 | Легированная сталь для сосудов под давлением

13CrMo4-5 | Легированная сталь для сосудов под давлением

13CrMo4-5 — это хромомолибденовая легированная сталь для высокотемпературных сосудов под давлением, соответствующая стандарту EN 10028-2. Название указывает приблизительно на хром 13% (13), где «Cr» обозначает хром, «Mo» — молибден, а «4-5» обозначает содержание молибдена 0,4-0,5%. Эта сталь обладает превосходной жаропрочностью, хорошей свариваемостью и сопротивлением ползучести. Распространенные области применения включают электростанции и нефтехимические заводы. Аналогичные марки — USA A387Gr.12, GB 12CrMo и JIS SFVAF12.

Описание

Что такое 13CrMo4-5?

13CrMo4-5 — это сталь, состоящая приблизительно из 13% хрома и 0,4-0,5% молибдена, образующая твердую легированную сталь. Она обладает превосходной жаропрочностью, хорошей свариваемостью и сопротивлением ползучести. Эта сталь в основном используется в условиях высокого давления на электростанциях и нефтехимических предприятиях. Она относится к категории термообработанной легированной стали и обычно обрабатывается методом горячей прокатки, что улучшает ее механические свойства.Почему стоит выбрать легированную сталь 13CrMo4-5 для сосудов высокого давления?

Спецификация продукта

| Категория | Подробности |

| Стандарт качества | EN 10028-2 |

| Сертификаты | ISO 9001, CE, EN 10216-2, ISO 14001, ISO 15156, HIC, IGC, IMPACT. |

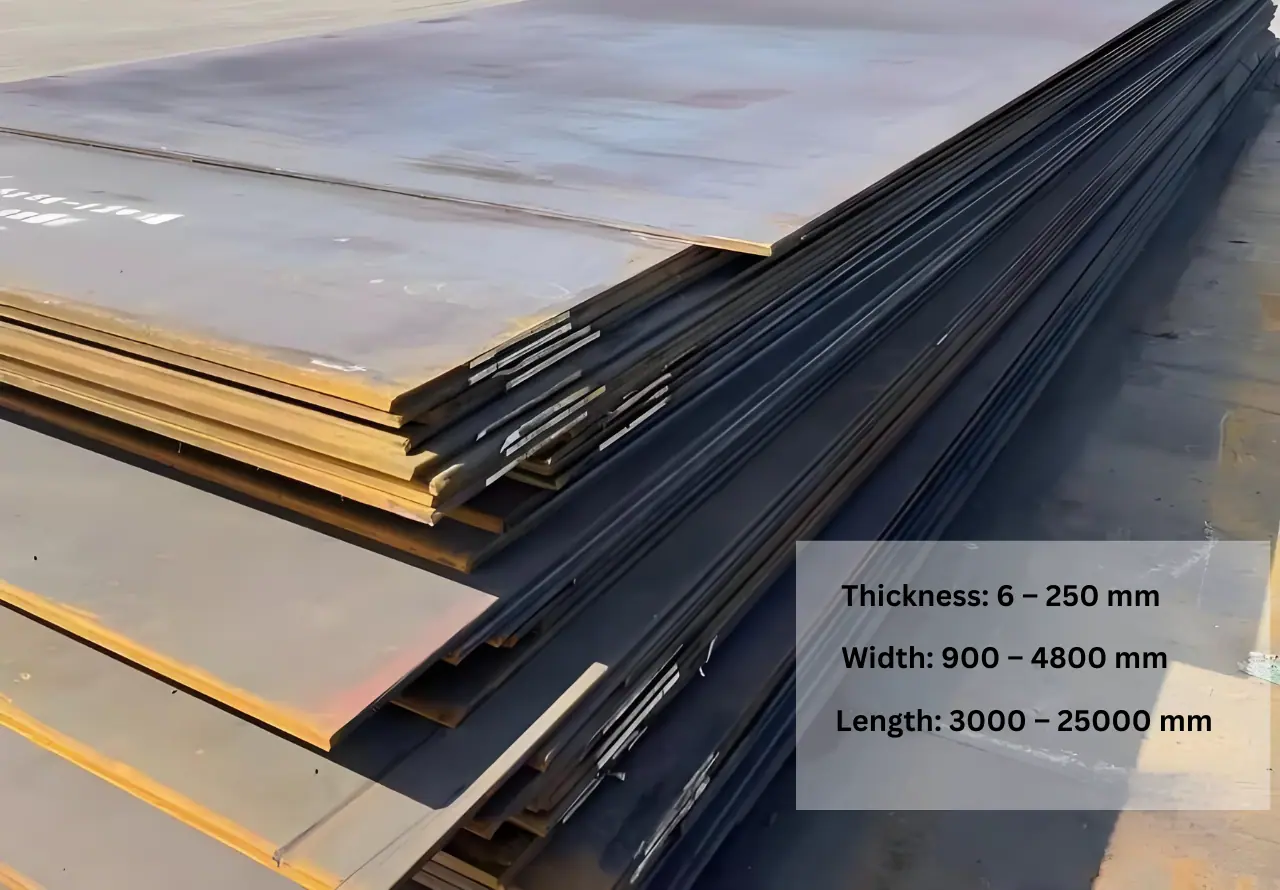

| Толщина | 6-150мм |

| Ширина | 900-4800мм |

| Длина | 3000-25000мм |

| Масса | Зависит от длины и ширины |

| Наружный диаметр (НД) | Трубы: 2 мм – 510 мм, Прутки: 10 мм – 300 мм |

| Внутренний диаметр (ВД) | Трубы: 12 мм – 500 мм |

| Допуски | Толщина: ±0,5 мм, Ширина: ±5 мм, Длина: ±10 мм |

| Технологии | Горячая прокатка |

| Служба обработки | Гибка, сварка, размотка, резка, штамповка |

| Формы | Стальная пластина для сосудов под давлением, стальной лист для сосудов под давлением, трубы, профили |

| MOQ (минимальный объем заказа) | 5 тонн (по фактическому тоннажу) |

| Время выполнения | Обычно 7-20 дней |

| Условия цены и оплаты | На основе требований заказчика, T/T, L/C |

| Порты | Циндао, Ляньюньган, Далянь |

| Страны экспорта | Юго-Восточная Азия, Центральная Азия, Европа, Россия, Южная Америка, Ближний Восток и т. д. |

| Способ доставки | Предлагает морские, воздушные и индивидуальные перевозки |

Химический состав

| Элемент | Содержание (%) |

|---|---|

| Углерод, С | 0.08 – 0.18 |

| Кремний, Si | макс 0,35 |

| Марганец, Mn | 0.4 – 1.0 |

| Фосфор, P | макс 0,025 |

| Сера, S | макс 0,01 |

| Хром, Cr | 0.7 – 1.15 |

| Молибден, Mo | 0.4 – 0.6 |

| Азот, N | макс 0,012 |

| Медь, Cu | макс 0,3 |

Механические свойства

| Свойство | Метрический | Империал |

|---|---|---|

| Предел прочности | 440 – 590 МПа | 63,8 – 85,6 тыс.фунтов на кв.дюйм |

| Предел текучести | ≥ 290 МПа | ≥ 42,1 тыс.фунтов на кв. дюйм |

| Твёрдость по Бринеллю (HB) | 135 – 180 | 135 – 180 |

| Твердость по Роквеллу (HRB) | 70 – 85 | 70 – 85 |

| Твёрдость по Виккерсу (HV) | 140 – 190 | 140 – 190 |

| Удлинение | 19 – 25% | 19 – 25% |

| Модуль упругости | 190 – 210 ГПа | 27,6 – 30,5 Мпси |

Данные после нормализующей обработки

| Свойство | Метрический | Империал |

|---|---|---|

| Предел прочности | 480 – 620 МПа | 69,6 – 89,9 тыс.фунтов на кв.дюйм |

| Предел текучести | ≥ 320 МПа | ≥ 46,4 тыс.фунтов на кв. дюйм |

| Твёрдость по Бринеллю (HB) | 150 – 200 | 150 – 200 |

| Твердость по Роквеллу (HRB) | 75 – 90 | 75 – 90 |

| Твёрдость по Виккерсу (HV) | 155 – 205 | 155 – 205 |

| Удлинение | 18 – 23% | 18 – 23% |

| Модуль упругости | 190 – 210 ГПа | 27,6 – 30,5 Мпси |

Отрасли и приложения

| Отрасли промышленности | Продукция |

|---|---|

| Генерация электроэнергии | Котлы, паровые турбины, теплообменники, пароперегреватели, напорные трубы |

| Нефтехимическая | Реакторы, Дистилляционные колонны, Теплообменники, Технологические сосуды, Резервуары для хранения |

| Нефть и газ | Оборудование для НПЗ, Сосуды под давлением, Трубопроводы, Факельные установки, Морские платформы |

| Химическая обработка | Химические реакторы, Сосуды под давлением, Теплообменники, Автоклавы, Резервуары для хранения |

| Энергетический сектор | Ядерные реакторы, Корпуса турбин, Теплоутилизационные парогенераторы, Напорные трубы, Теплообменники |

| Судостроение | Котлы, напорные баки, теплообменники, трубопроводные системы, паровые системы |

| Промышленное оборудование | Цилиндры высокого давления, Паропроводы, Конструкционные элементы, Теплообменники, Котлы |

| Оборудование для термической обработки | Детали печей, Теплообменники, Печи, Сосуды под давлением, Паропроводы |

| Металлургическая Переработка | Плавильные емкости, Рафинировочные печи, Теплообменники, Котлы, Напорные трубопроводы |

Упаковка

Когда дело доходит до упаковки сосудов высокого давления из легированной стали 13CrMo4-5, SteelPRO Group обеспечивает самые высокие стандарты для защиты продукта и удовлетворения потребностей клиентов. Вот четыре основных преимущества:

- Индивидуальные упаковочные решения: Мы предлагаем индивидуальные методы упаковки, такие как деревянные ящики, стальные ленты или водонепроницаемая обертка, в зависимости от требований заказчика и способа транспортировки.

- Защита от коррозии: Вся сталь 13CrMo4-5 обработана антикоррозийным покрытием или упакована во влагостойкие материалы для предотвращения окисления во время транспортировки.

- Надежное крепление: Каждая партия надежно закрепляется прочной стальной лентой, чтобы избежать любых перемещений или повреждений во время транспортировки, гарантируя безопасную доставку продукции.

- Соответствие международным стандартам: Наша упаковка соответствует мировым стандартам транспортировки стальной продукции, что сводит к минимуму риск повреждения и обеспечивает беспрепятственное прохождение таможенной очистки.

Эти преимущества демонстрируют нашу приверженность поставке клиентам высококачественной и защищенной стальной продукции.

Обработка

Варианты продукции для термообработки 13CrMo4-5

Ниже представлены различные формы легированной стали 13CrMo4-5 для сосудов под давлением, которые мы поставляем после термической обработки:

- Нормализованная сталь 13CrMo4-5: Поставляется в нормализованном состоянии, обработанном при температуре 900-950°С для улучшения механических свойств, обеспечения повышенной прочности и вязкости.

- Отожженная сталь 13CrMo4-5: Сталь смягчается отжигом при температуре около 650–700 °C, подходит для применений, требующих хорошей обрабатываемости и повышенной пластичности.

- Закаленная и отпущенная сталь 13CrMo4-5: Термическая обработка с закалкой и последующим отпуском при температуре 600-700°С обеспечивает повышенную твердость и отличную стойкость к высоким температурам.

- Сталь 13CrMo4-5 со снятым напряжением: Прошел термическую обработку для снятия внутренних напряжений, идеально подходит для применений со строгими требованиями к размерной стабильности.

- Горячекатаная сталь 13CrMo4-5: Доступно в прокатанном состоянии, что является экономически эффективным решением в случаях, когда не требуется высокая точность.

Мы можем адаптировать процесс термообработки под ваши конкретные потребности и требования проекта.

13CrMo4-5 Поверхностная обработка

Ниже приведены виды обработки поверхности, которые мы можем предложить для легированной стали 13CrMo4-5 для сосудов высокого давления:

- Дробеструйная обработка: Удаляет поверхностные загрязнения, окалину и ржавчину, обеспечивая чистую и гладкую поверхность, готовую к дальнейшей обработке или нанесению покрытия.

- Маринование: Использует химическую обработку для удаления окисления, прокатной окалины и других загрязнений, в результате чего поверхность становится гладкой и однородной.

- Фосфатирование: Наносит защитное фосфатное покрытие, повышающее коррозионную стойкость и улучшающее адгезию краски.

- Гальванизация: Покрывает сталь слоем цинка, обеспечивая надежную защиту от коррозии, особенно на открытом воздухе или во влажной среде.

- Антикоррозийное покрытие: Добавляет слой коррозионно-стойкого материала, продлевая срок службы стали в суровых условиях.

- Масляное покрытие: Создает временный слой защиты от ржавчины, идеально подходящий для защиты стали во время хранения или транспортировки.

- Рисование: Добавляет слой защитной или декоративной краски, улучшая внешний вид и обеспечивая дополнительный барьер от коррозии.

Поставщик стали для сосудов высокого давления 13CrMo4-5

Как доверенный Поставщик стали для сосудов под давлением из сплава 13CrMo4-5, мы предлагаем несколько ключевых преимуществ:

- Конкурентоспособные цены и своевременная доставка: Мы предлагаем конкурентоспособные цены и гарантируем своевременную доставку, соответствующую срокам реализации вашего проекта.

- Полный ассортимент продукции: Мы предлагаем полный ассортимент изделий из стали 13CrMo4-5 различных размеров и форм, адаптированных к вашим конкретным потребностям.

- Строгий контроль качества и сертификация: Каждая партия 13CrMo4-5 проходит строгие испытания с получением сертификатов, таких как EN 10204 3.1/3.2, что гарантирует соответствие международным стандартам.

- Индивидуальные решения: Мы предлагаем полностью настраиваемые опции, включая специальные виды термообработки и отделки поверхности, соответствующие уникальным требованиям вашего проекта.

- Надежная упаковка и эффективная логистика: Наша продукция надежно упакована, чтобы предотвратить повреждения во время транспортировки, а наша эффективная система логистики обеспечивает быстрое и прозрачное обновление информации о доставке.

Мы стремимся поставлять высококачественную сталь 13CrMo4-5 и оказывать профессиональную поддержку на протяжении всего процесса выполнения вашего заказа.

Наши услуги

SteelPRO Group – производитель и поставщик решений для специальной стали, предлагающий многоотраслевые прикладные решения и индивидуальные услуги, качество 100% бесплатно, сопровождающий клиентов в их росте!

Наш контроль качества

- Округлость

- Терпимость

- Микроструктура

- Неразрушающий контроль

- Разрушающий контроль

- Управление процессами

Обработка интеграции услуг

- Сварка

- Изготовление Металла

- Обработка на станках с ЧПУ

- Токарный станок

- Формирование

Можете ли вы обеспечить прослеживаемость партии 13CrMo4-5?

Да, мы предлагаем полную прослеживаемость партий 13CrMo4-5, гарантируя прозрачность от поиска сырья до поставки готовой продукции.

Каков срок годности 13CrMo4-5 при хранении?

При надлежащих условиях хранения, таких как сухая и контролируемая среда, 13CrMo4-5 может храниться в течение нескольких лет без ухудшения качества.

Существуют ли ограничения по размеру для заказов 13CrMo4-5?

Мы поставляем 13CrMo4-5 в широком диапазоне размеров и можем выполнять как небольшие, так и крупные индивидуальные заказы в соответствии с потребностями вашего проекта.

Как вы обрабатываете срочные заказы?

Мы уделяем первостепенное внимание производству и ускоряем доставку через надежных логистических партнеров для срочных заказов, чтобы гарантировать своевременную доставку.

Какова ваша политика в отношении устранения дефектов продукции?

В случае обнаружения дефектов мы следуем четкой процедуре разрешения, включая замену или компенсацию, подкрепленной нашими гарантиями качества.

Предлагаете ли вы техническую поддержку после продажи?

Да, мы предоставляем комплексную техническую поддержку после покупки, включая руководство по обращению с материалами, изготовлению и применению.

КОНТАКТ

КОНТАКТ

Сертификаты

Другие продукты

-

-

Группа компаний SteelPRO предлагает листы из высокопрочной конструкционной стали FH550 для судостроения....

-

Группа компаний SteelPRO предлагает на складе листовую судостроительную сталь высокой прочности DH550....

-

SteelPro Group предлагает высокопрочную сталь FH36 для судостроения. Она имеет...