13CrMo4-5 | Alloy Pressure Vessel Steel

13CrMo4-5 | Alloy Pressure Vessel Steel

13CrMo4-5 is a chromium-molybdenum alloy steel for high-temperature pressure vessels, conforming to the EN 10028-2 standard. The name indicates approximately 13% chromium (13), with “Cr” for chromium, “Mo” for molybdenum, and “4-5” representing 0.4-0.5% molybdenum content. This steel offers excellent high-temperature strength, good weldability, and creep resistance. Common applications include power and petrochemical plants. Similar grades are USA A387Gr.12, GB 12CrMo, and JIS SFVAF12.

Description

What is 13CrMo4-5?

13CrMo4-5 is a steel composed of approximately 13% chromium and 0.4-0.5% molybdenum, forming a solid alloy steel. It possesses excellent high-temperature strength, good weldability, and resistance to creep. This steel is primarily used in high-pressure applications in power plants and petrochemical facilities. It is categorized as heat-treated alloy steel and is typically processed through hot rolling, which enhances its mechanical properties.Why Choose 13CrMo4-5 Alloy Pressure Vessel Steel?

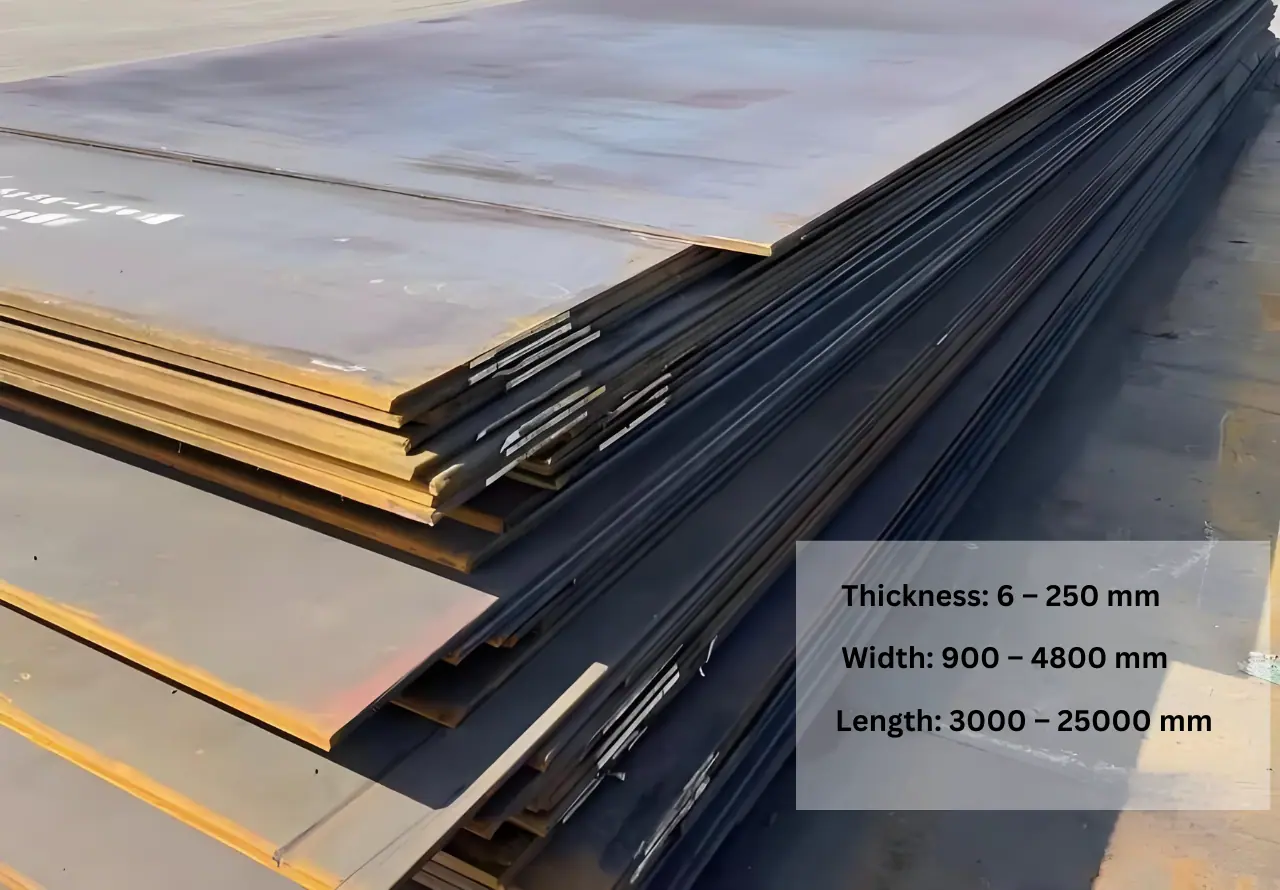

Product Specification

| Category | Details |

| Quality Standard | EN 10028-2 |

| Certifications | ISO 9001, CE, EN 10216-2, ISO 14001, ISO 15156, HIC、IGC、IMPACT |

| Thickness | 6-150mm |

| Width | 900-4800mm |

| Length | 3000-25000mm |

| Weight | Depends on length and width |

| Outer diameter (OD) | Pipes:2 mm – 510 mm, Bars: 10 mm to 300 mm |

| Inner diameter (ID) | Pipes: 12 mm – 500 mm |

| Tolerances | Thickness: ±0.5mm, Width: ±5mm, Length: ±10mm |

| Technology | Hot Rolling |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Shapes | Pressure Vessel Steel Plate, Pressure Vessel Steel Sheet, Pipes, Profiles |

| MOQ (Minimum Order Quantity) | 5 tons (according to the actual tonnage) |

| Lead Time | Typically 7-20 days |

| Price Terms & Payment | Based on customer requirements, T/T, L/C |

| Ports | Qingdao, Lianyungang, Dalian |

| Export Countries | Southeast Asia, Central Asia, Europe, Russia, South America, Middle East, etc. |

| Shipping Method | Offers Sea, Air and Customized Shipping |

Chemical Compositions

| Element | Content (%) |

|---|---|

| Carbon, C | 0.08 – 0.18 |

| Silicon, Si | max 0.35 |

| Manganese, Mn | 0.4 – 1.0 |

| Phosphorus, P | max 0.025 |

| Sulfur, S | max 0.01 |

| Chromium, Cr | 0.7 – 1.15 |

| Molybdenum, Mo | 0.4 – 0.6 |

| Nitrogen, N | max 0.012 |

| Copper, Cu | max 0.3 |

Mechanical Properties

| Property | Metric | Imperial |

|---|---|---|

| Tensile Strength | 440 – 590 MPa | 63.8 – 85.6 ksi |

| Yield Strength | ≥ 290 MPa | ≥ 42.1 ksi |

| Brinell Hardness (HB) | 135 – 180 | 135 – 180 |

| Rockwell Hardness (HRB) | 70 – 85 | 70 – 85 |

| Vickers Hardness (HV) | 140 – 190 | 140 – 190 |

| Elongation | 19 – 25% | 19 – 25% |

| Elastic Modulus | 190 – 210 GPa | 27.6 – 30.5 Mpsi |

Data After Normalizing Processing

| Property | Metric | Imperial |

|---|---|---|

| Tensile Strength | 480 – 620 MPa | 69.6 – 89.9 ksi |

| Yield Strength | ≥ 320 MPa | ≥ 46.4 ksi |

| Brinell Hardness (HB) | 150 – 200 | 150 – 200 |

| Rockwell Hardness (HRB) | 75 – 90 | 75 – 90 |

| Vickers Hardness (HV) | 155 – 205 | 155 – 205 |

| Elongation | 18 – 23% | 18 – 23% |

| Elastic Modulus | 190 – 210 GPa | 27.6 – 30.5 Mpsi |

Industries & Applications

| Industries | Products |

|---|---|

| Power Generation | Boilers, Steam turbines, Heat exchangers, Superheaters, Pressure pipes |

| Petrochemical | Reactors, Distillation columns, Heat exchangers, Process vessels, Storage tanks |

| Oil and Gas | Refinery equipment, Pressure vessels, Pipelines, Flare stacks, Offshore platforms |

| Chemical Processing | Chemical reactors, Pressure vessels, Heat exchangers, Autoclaves, Storage tanks |

| Energy Sector | Nuclear reactors, Turbine casings, Heat recovery steam generators, Pressure pipes, Heat exchangers |

| Shipbuilding | Boilers, Pressure tanks, Heat exchangers, Piping systems, Steam systems |

| Industrial Machinery | High-pressure cylinders, Steam piping, Structural components, Heat exchangers, Boilers |

| Heat Treatment Equipment | Furnace parts, Heat exchangers, Kilns, Pressure vessels, Steam piping |

| Metallurgical Processing | Smelting vessels, Refining furnaces, Heat exchangers, Boilers, Pressure piping |

Packing

When it comes to packing 13CrMo4-5 Alloy Pressure Vessel Steel, SteelPRO Group ensures the highest standards to protect the product and meet customer needs. Here are four key advantages:

- Custom Packaging Solutions: We offer tailored packaging methods such as wooden crates, steel straps, or waterproof wrapping, depending on customer requirements and transportation mode.

- Corrosion Protection: All 13CrMo4-5 steel is treated with anti-corrosion coating or wrapped in moisture-resistant materials to prevent oxidation during transit.

- Secure Fastening: Each shipment is tightly secured using durable steel strapping to avoid any movement or damage during transportation, ensuring the product arrives safely.

- Compliance with International Standards: Our packaging complies with global standards for shipping steel products, minimizing the risk of damage and ensuring smooth customs clearance.

These advantages showcase our commitment to delivering customers high-quality, protected steel products.

Machining

13CrMo4-5 Heat Treatment Product Options

Here are the different forms of 13CrMo4-5 Alloy Pressure Vessel Steel we provide after heat treatment:

- Normalized 13CrMo4-5 Steel: Delivered in normalized condition, treated at 900-950°C to improve mechanical properties, ensuring enhanced strength and toughness.

- Annealed 13CrMo4-5 Steel: Softened by annealing at around 650-700°C, suitable for applications requiring good machinability and improved ductility.

- Quenched and Tempered 13CrMo4-5 Steel: Heat treated with quenching followed by tempering at 600-700°C, providing increased hardness and excellent high-temperature resistance.

- Stress Relieved 13CrMo4-5 Steel: Heat treated to relieve internal stresses, ideal for applications with strict dimensional stability requirements.

- Hot Rolled 13CrMo4-5 Steel: Available in as-rolled condition, offering a cost-effective solution where high precision is not required.

We can customize the heat treatment process based on your specific needs and project requirements.

13CrMo4-5 Surface Finish

Here are the surface treatments we can provide for 13CrMo4-5 Alloy Pressure Vessel Steel:

- Shot Blasting: Removes surface impurities, scales, and rust, providing a clean and smooth surface ready for further processing or coating.

- Pickling: Uses chemical treatment to remove oxidation, mill scale, and other contaminants, resulting in a smooth and uniform surface.

- Phosphating: Applies a protective phosphate coating that enhances corrosion resistance and improves paint adhesion.

- Galvanizing: Coats the steel with a layer of zinc, offering strong protection against corrosion, especially in outdoor or humid environments.

- Anti-corrosion Coating: Adds a layer of corrosion-resistant material, extending the life of the steel in harsh environments.

- Oil Coating: Provides a temporary rust prevention layer, ideal for protecting the steel during storage or transportation.

- Painting: Adds a layer of protective or decorative paint, enhancing appearance and providing an extra barrier against corrosion.

13CrMo4-5 Pressure Vessel Steel Supplier

As a trusted 13CrMo4-5 Alloy Pressure Vessel Steel Supplier, we offer several key advantages:

- Competitive Pricing and On-time Delivery: We provide competitive pricing while ensuring timely delivery to meet your project deadlines.

- Complete Product Range: We offer a full range of 13CrMo4-5 steel products in various sizes and forms, tailored to your specific application needs.

- Strict Quality Assurance and Certification: Every batch of 13CrMo4-5 undergoes rigorous testing with certifications like EN 10204 3.1/3.2, ensuring compliance with international standards.

- Custom Solutions: We provide fully customizable options, including specific heat treatments and surface finishes, to match your unique project requirements.

- Secure Packaging and Efficient Logistics: Our products are safely packaged to prevent damage during transit, and our efficient logistics system ensures fast and transparent shipping updates.

We are dedicated to delivering high-quality 13CrMo4-5 steel with professional support throughout your order process.

Our Service

SteelPRO Group – manufacturer and solution provider for special steel, offering multi-industry application solutions and customised services, 100% quality free, accompanying customers in their growth!

Our Quality Control

- Roundness

- Tolerance

- Microstructure

- Non-Destructive Testing

- Destructive Testing

- Process Control

Service Integration Processing

- Welding

- Metal Fabrication

- CNC Machining

- Lathe

- Forming

Can You Provide Batch Traceability For 13CrMo4-5?

Yes, we offer full batch traceability for 13CrMo4-5, ensuring transparency from raw material sourcing through final delivery.

What Is The Shelf Life Of 13CrMo4-5 In Storage?

Under proper storage conditions, such as a dry and controlled environment, 13CrMo4-5 can be stored for several years without degradation in quality.

Are There Any Size Limitations For 13CrMo4-5 Orders?

We supply 13CrMo4-5 in a wide range of sizes, and we can accommodate both small and large custom orders according to your project needs.

How Do You Handle Urgent Orders?

We prioritize production and expedite shipping through reliable logistics partners for urgent orders to ensure timely delivery.

What Is Your Policy On Handling Product Defects?

In case of any defects, we follow a clear resolution process, including replacement or compensation, backed by our quality assurance guarantees.

Do You Offer Technical Support Post-Sale?

Yes, we provide comprehensive technical support after purchase, including material handling, fabrication, and application guidance.

CONTACT

CONTACT

Certifications

Other Products

-

-

SteelPRO Group offers FH550 high-strength structural steel plates for shipbuilding....

-

SteelPRO Group offers DH550 high-strength shipbuilding steel plates in stock....

-

SteelPro Group offers FH36 high-strength steel for shipbuilding. It has...