DC04 Galvanized Steel Coil

DC04 Galvanized Steel Coil

We are a manufacturer and supplier of DC04 galvanized steel coils, which are widely used in automobile manufacturing, home appliance housings and deep-drawn parts. We also provide standard DC04, DC01, Q195, Q235 galvanized steel sheets, DC01, Q195 galvanized steel coils, etc., and provide customized cutting, surface treatment and logistics services to ensure that your needs are met.

- Standard: EN 10130, EN 10346, ASTM A653 / A653M

- Grade: DC04, Q235, SGCD2, etc.

- Technology: Cold Rolling, Hot-dip Galvanizing, Electro-galvanizing

- Certification: ISO 9001, CE

DC04 Galvanized Steel Coil

DC04 Galvanized Steel Coil

Product Specifications

Product Specifications

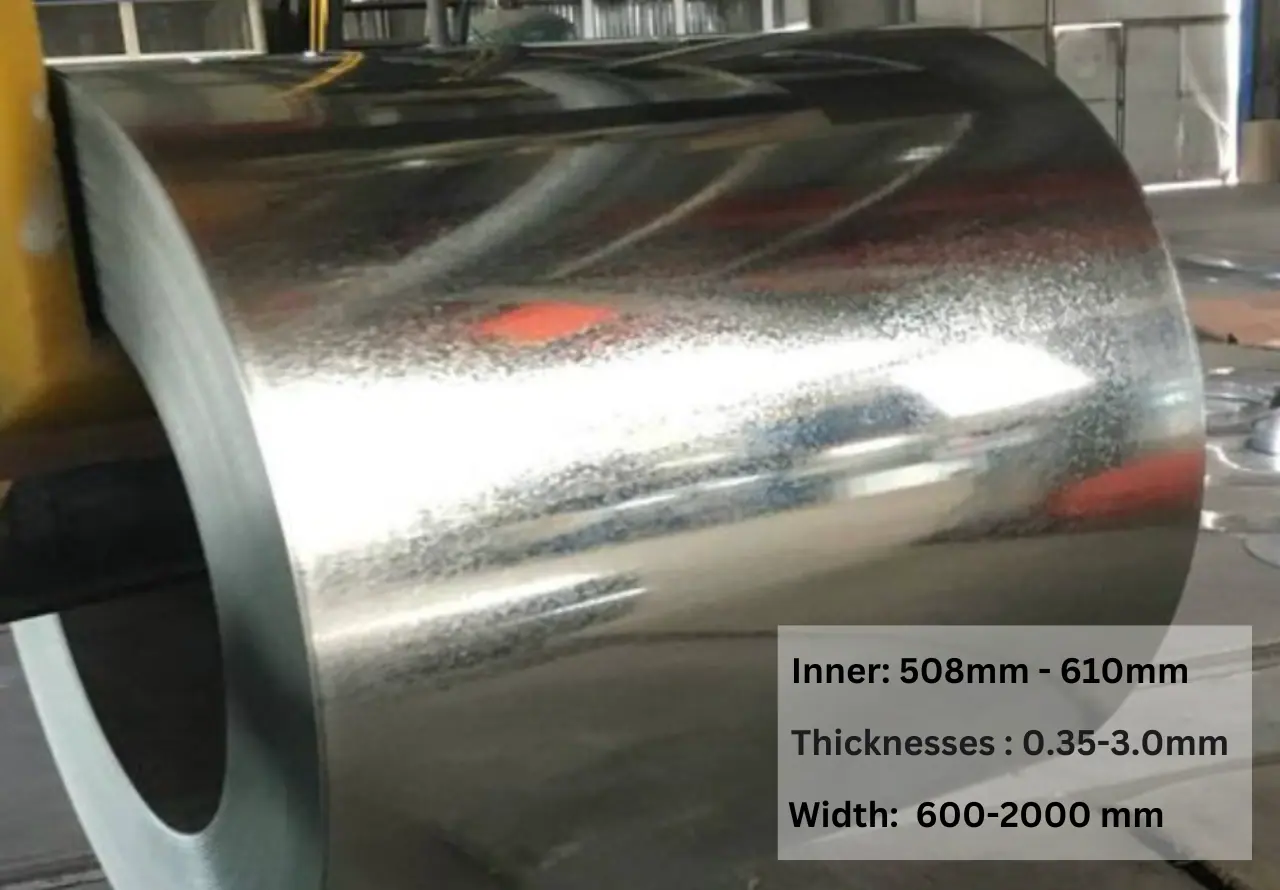

| Product Name | DC04 Galvanized Steel Coil |

| Substrate | DC04 Cold-rolled steel |

| Thickness | 0.35mm~3mm, Customized |

| Width | 600mm – 2000mm, Customized |

| Length | Customized |

| Coil Inner | 508mm – 610mm, Customized |

| Zinc Layer | 30g – 275g/m² |

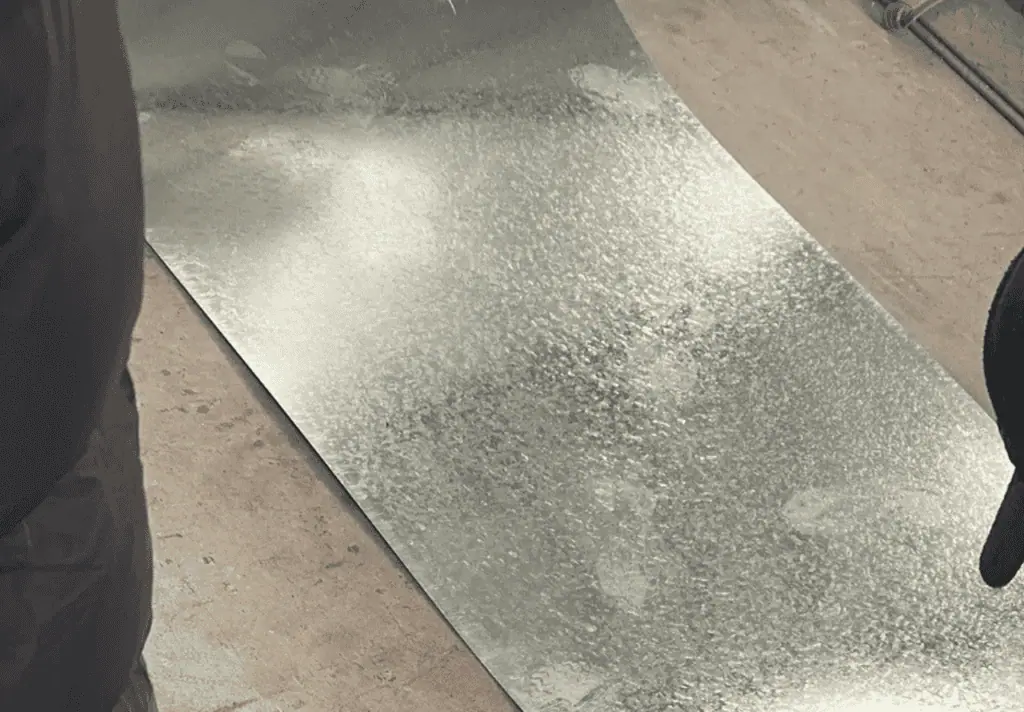

| Spangle | big, regular, mini, and zero spangles |

| Surface Treatment | anti-finger print /skin pass/oiled/ dry/chromated/Embossed/Lamination |

| Surface quality | A, B |

| Test | Zinc Coating Thickness Test, Bend, Cross-hatch, Salt Spray Test, Tensile Test, etc |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Invoicing | by actual weight |

| Delivery Time | 7-15 days |

| Payment | T/T, L/C, Credit Card |

| Port | Shanghai, Qingdao or according to your requirement |

| Packaging Details | In bundles, in bulk, customized packing |

Chemical Compositions

Chemical Compositions

| Element | Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Nitrogen (N) |

|---|---|---|---|---|---|

| Percentage (%) | ≤ 0.08 | ≤ 0.40 | ≤ 0.03 | ≤ 0.03 | ≤ 0.01 |

Mechanical properties

Mechanical properties

| Mechanical Property | Typical Value |

|---|---|

| Tensile Strength (MPa) | 270 – 350 |

| Yield Strength (MPa) | 140 – 240 |

| Elongation (%) | ≥ 38 |

| Vickers Hardness (HV) | 90 – 120 |

| Brinell Hardness (HB) | ≤ 70 |

| Rockwell Hardness (HRB) | ≤ 70 |

| Elastic Modulus (GPa) | ~210 |

Industries & Applications

Industries & Applications

- Automobile manufacturing: used for body parts and interior parts such as doors, hoods, roofs, etc., due to its good formability and corrosion resistance, it can cope with complex shapes and long-term use requirements.

- Household appliances: suitable for refrigerators, washing machines, microwave ovens and other home appliance housings, with smooth surface, easy to paint, and can resist corrosion in humid environments.

- Construction industry: used for building materials such as roofs, walls, guardrails, etc., the galvanized layer provides long-lasting rust protection and is suitable for outdoor applications.

- Electrical equipment housing: widely used in electrical equipment housings such as electrical cabinets and distribution boxes to ensure the safety and stability of the equipment during long-term operation.

- Furniture manufacturing: can be used to make metal furniture frames or decorative parts, with excellent appearance and corrosion resistance, improving the durability and beauty of furniture.

Other Infomation

Other Infomation

We have two surface qualities for you to choose from:

- Grade A, which is a high-quality surface. If you are particularly picky about the appearance of the product, you can choose it.

- Grade B is a general quality surface. If the appearance requirements are not so high, it can meet your needs.

We also provide different surface treatments. You can choose the appropriate treatment method according to your needs. If you are unable to make a decision, you can contact our experts for consultation.

- P, which is a phosphating treatment, can make the steel more corrosion-resistant and have stronger adhesion.

- PC, phosphating and chemical treatment together, the protection effect is even better.

- C, chemical treatment, or passivation, to prevent steel from rusting or corrosion.

- PCO, phosphating, chemical treatment and oiling, this durability is great.

- CO, chemical treatment, or passivation, and oiling, the anti-rust effect is great.

- PO, phosphating and oiling, double protection, let you feel more at ease.

- O, which is oiling, to prevent temporary oxidation of steel, simple and practical.

- S, coating sealing, if you want long-term protection, choose it.

- U, untreated, you can play with it, treat it however you want.

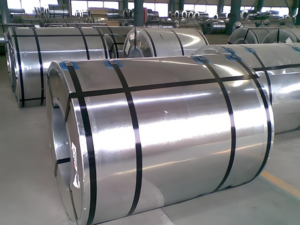

Our Inventory

Our Inventory

SteelPRO Group is a top steel supplier with an annual production capacity of more than 1 million tons, operating three independent plants and partnering with renowned manufacturers. We offer a comprehensive range of services, including production, processing, and efficient logistics. Our strengths lie in stable supply, diverse product range, high quality standards, competitive prices, fast delivery times, and excellent after-sales support.

Main products: steel coils, steel plates, rebar, carbon steel, stainless steel, galvanized steel, structural steel, and specialty steel for industries such as construction, automotive, manufacturing, and energy.

Packing

Packing

SteelPRO Group exports to the Middle East, South America, Europe, and Southeast Asia, enjoying strong international sales. We offer tailored packaging solutions for various steel types, ensuring secure, sealed, and anti-corrosion protection. Our shipping procedures include regular inspection and maintenance of transportation equipment to prevent exposure to moisture or water accumulation. Additionally, we label all shipments with detailed information following international standards, guaranteeing the safety and quality of the steel throughout the transportation process.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

Can I visit your factory?

Of course, you are welcome to visit our factory. Please contact us in advance so that we can arrange a suitable visit time for you. We will do our best to guide you and ensure that your visit experience is both fulfilling and enjoyable.

What are your prices?

You can get factory wholesale prices. Since we have our own factories and maintain close cooperation with large factories, and sell through first-line agents, we are able to ensure the stability of product quality while providing competitive prices.

What product information do I need to provide?

You need to provide the brand, width, thickness, coating and tonnage you need to purchase.

Are the products quality checked before loading?

Yes, all our products must pass three inspections throughout the manufacturing process, including production and warehouse random testing, and unqualified products will be destroyed before shipment.

Do you provide samples? Free or additional?

Yes, we can provide free samples for quality evaluation. However, the freight is usually borne by your company.

Do you accept third-party inspections?

Yes, we absolutely accept.

CONTACT

Certificates and Cooperation

Certificates and Cooperation