SPCC Galvanized Steel Coil

SPCC Galvanized Steel Coil

SteelPRO Group is a leading SPCC steel coil manufacturer and supplier, providing high-quality SPCC galvanized steel coils, plates, PPGI, pipes and other grades and types of galvanized steel products. With advanced production technology, we also provide personalized surface treatment services and size customization services.

- Standard: GB/T 2518, JIS G 3302, ASTM A653, EN 10346, etc.

- Grades: DC01, SPCC, CS Type A, CS Type B, DX51D, etc

- Technology: Cold Rolling, Hot-dip Galvanizing

- Base material: Cold rolled sheet

- Certification: ISO 9001, CE

SPCC Galvanized Steel Coil

SPCC Galvanized Steel Coil

Product Specifications

Product Specifications

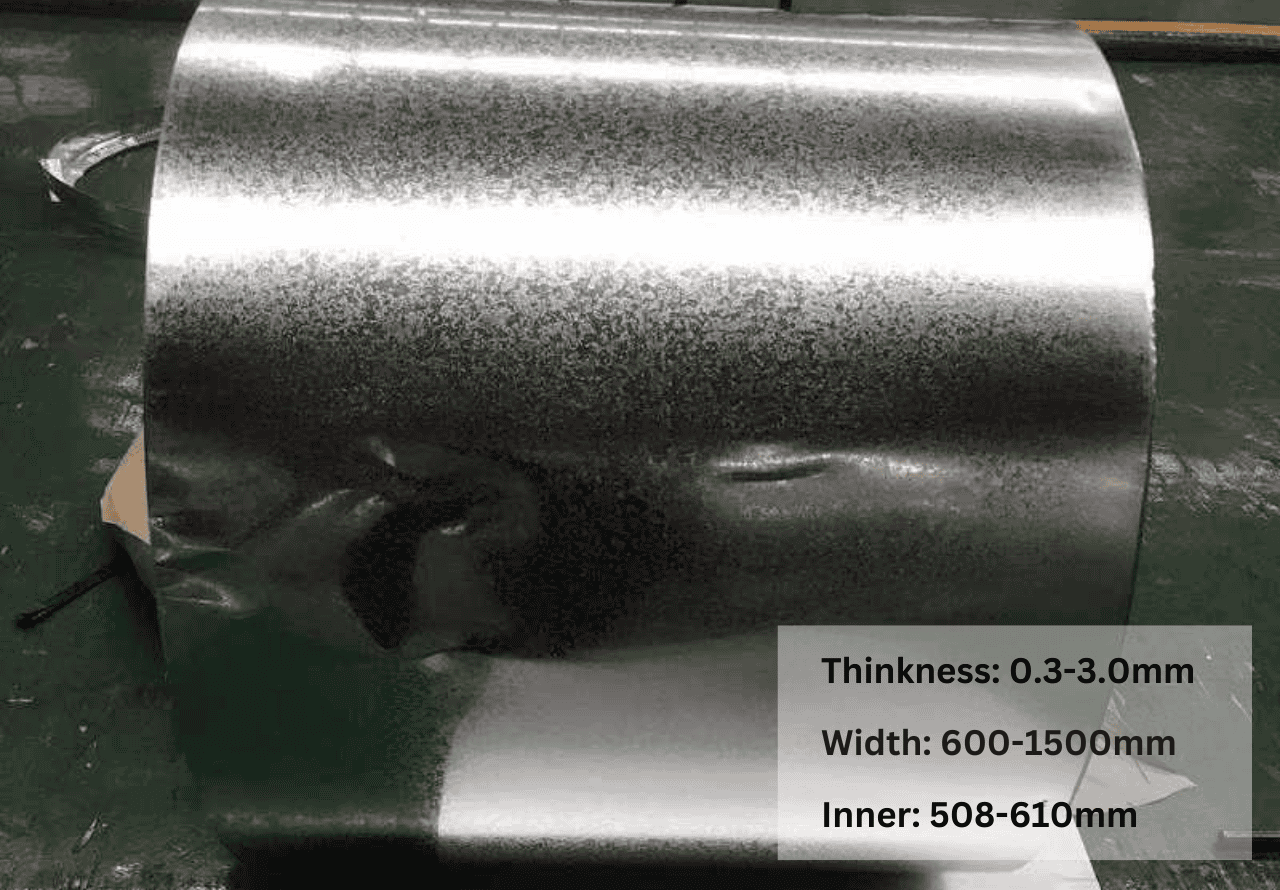

| Product Name | SPCC Galvanized Steel Coil |

| Thickness | 0.3mm~3mm, Customized |

| Width | 600mm – 1500mm, Customized |

| Length | Customized |

| Coil Inner | 508mm – 610mm, Customized |

| Zinc Layer | 30g – 275g/m² |

| Spangle | big, regular, mini, and zero spangles |

| Surface Treatment | anti-finger print /skin pass/oiled/ dry/chromated/Embossed/Lamination |

| Surface quality | A, B |

| Test | Zinc Coating Thickness Test, Bend, Cross-hatch, Salt Spray Test, Tensile Test, etc. |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Invoicing | by actual weight |

| Delivery Time | 7-15 days |

| Payment | T/T, L/C, Credit Card |

| Port | Shanghai, Qingdao or according to your requirement |

| Packaging Details | In bundles, in bulk, customized packing |

Chemical Compositions

Chemical Compositions

| Element | Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon (Si) |

|---|---|---|---|---|---|

| Composition (%) | ≤ 0.15 | ≤ 0.60 | ≤ 0.05 | ≤ 0.05 | ≤ 0.03 |

Mechanical properties

Mechanical properties

| Property | Typical Value |

|---|---|

| Tensile Strength (MPa) | 270 – 410 |

| Yield Strength (MPa) | 140 – 280 |

| Elongation (%) | ≥ 28 |

| Vickers Hardness (HV) | 80 – 120 |

| Brinell Hardness (HB) | 70 – 100 |

| Rockwell Hardness (HRB) | 55 – 75 |

| Elastic Modulus (GPa) | Approximately 210 |

Industries & Applications

Industries & Applications

- Automotive Industry: Used in manufacturing interior parts, chassis, and structural components that require corrosion resistance and moderate strength.

- Appliance Manufacturing: Ideal for home appliances such as refrigerators, washing machines, and air conditioners due to its durability and smooth surface.

- Building and Construction Materials: Applied to roofing, siding, piping, and framing materials, providing weather resistance and strength for indoor and outdoor use.

- Furniture and Cabinets: Used in metal furniture, storage cabinets, and shelving due to its formability, corrosion resistance, and smooth surface.

- Electrical and Electronic Enclosures: Suitable for manufacturing enclosures, boxes, and panels, providing corrosion protection while maintaining structural integrity.

- HVAC Systems: Used in heating, ventilation, and air conditioning systems, including pipes and other components exposed to humid environments.

- Packaging and Container Manufacturing: Used in the production of steel drums, barrels, and other packaging containers, providing durability and corrosion resistance.

- Signs and Billboards: Used in outdoor signs and display boards, featuring a smooth surface and weather resistance.

Other Infomation

Other Infomation

Electromagnetic Properties

SPCC cold-rolled galvanized steel coils excel in electromagnetic properties. Through composition and thickness control, the steel coils effectively reduce electromagnetic interference (EMI) and protect the normal operation of electrical equipment. The conductivity of the galvanized layer provides a good shielding effect for the material, which is especially suitable for applications requiring electromagnetic shielding. It is widely used in products such as electromagnetic shielding shells and home appliance housings, becoming a cost-effective choice in electrical applications.

There are some common suffixes for SPCC galvanized steel, which help to quickly identify the surface and treatment of SPCC steel.

- SPCC-SD: High-finish surface, suitable for occasions with high appearance requirements, such as home appliance housings.

- SPCC-SB: Basic surface treatment, suitable for applications with low surface requirements such as internal structural parts.

- SPCC-2B: Slightly cold-rolled, moderate smoothness, commonly used in home appliances and furniture.

- SPCC-FB: Bright surface treatment, bright surface, suitable for high-end decorative parts.

- SPCC-P: Phosphating treatment, enhanced rust resistance, suitable for subsequent coating products.

- SPCC-CT: Chromic acid passivation treatment, provides corrosion resistance, suitable for humid environment applications.

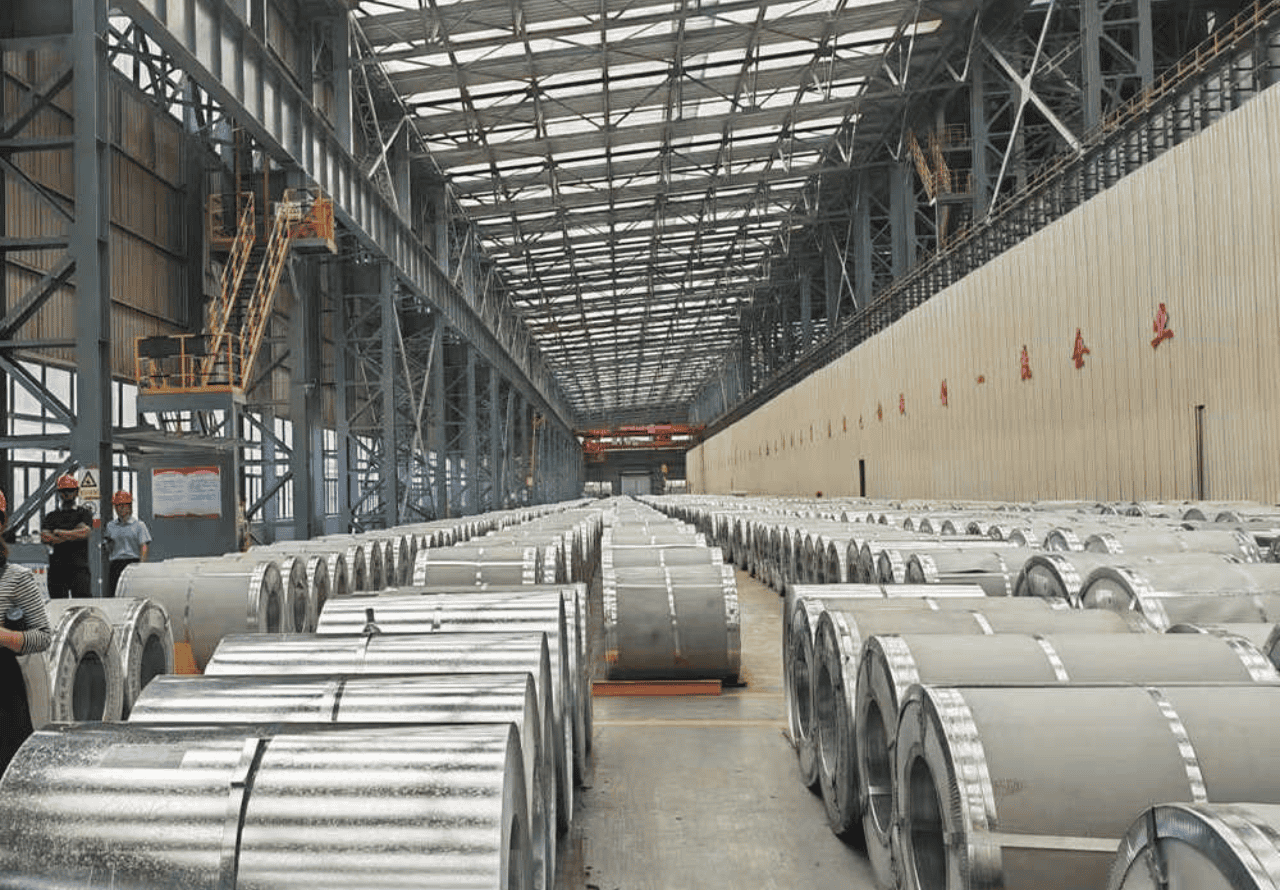

Our Inventory

Our Inventory

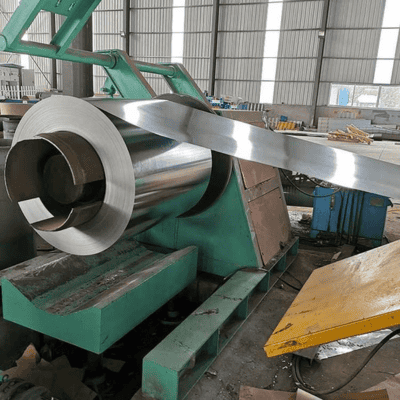

As an excellent galvanized steel manufacturer and supplier, SteelPRO Group’s production facilities adopt internationally leading technologies and are equipped with multiple efficient production lines to ensure stable large-scale production capabilities. We have established long-term cooperation with top raw material suppliers and strictly control product quality to ensure that each batch of steel coils meets international standards and customer needs. From order processing to production and delivery, we have a complete supply chain system support to ensure a quick response to customers’ personalized needs, helping you gain an advantage in the fiercely competitive market.

Main products: steel coils, steel plates, rebar, carbon steel, stainless steel, galvanized steel, structural steel, and specialty steel for industries such as construction, automotive, manufacturing, and energy.

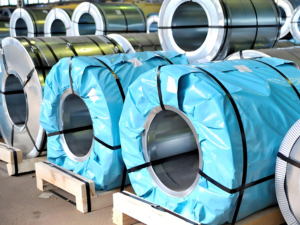

Packing

Packing

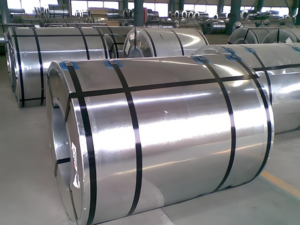

SteelPRO Group’s SPCC Galvanized Steel Coils are securely packaged to ensure safe delivery. Each coil is wrapped in moisture-resistant paper and securely bound with metal straps to prevent shifting during transport. Additionally, protective outer metal covers are applied to safeguard against environmental exposure and damage. We ensure that every coil reaches our customers in pristine condition, ready for immediate use in your projects.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

Are SteelPRO's SPCC galvanized steel coils suitable for outdoor use?

Yes, our SPCC galvanized steel coils are designed with a premium zinc coating that resists rust and corrosion for a variety of outdoor applications. However, for extreme environments, additional coatings may improve performance.

What finishes are available for SteelPRO's SPCC steel coils?

We offer a variety of finishes for our SPCC steel coils, including SPCC-SD for higher gloss and smoothness and SPCC-SB for basic applications. Each finish option is tailored to meet the specific aesthetic and functional needs of different applications, ensuring versatility in design and functionality.

Are SteelPRO's SPCC galvanized steel coils available in custom sizes and thicknesses?

Yes, our SPCC galvanized steel coils can be customized to specific requirements in terms of width, thickness, and other specifications. We work closely with our customers to deliver products that exactly match their project needs, from large-scale industrial orders to small specialty applications.

What makes SteelPRO Group different from other SPCC coil manufacturers?

SteelPRO Group stands out with high production capacity, advanced production lines, and strategic partnerships with global raw material suppliers. Our commitment to quality and innovation, coupled with a responsive supply chain, ensures that we consistently deliver high-performance steel products on time.

Does SteelPRO Group meet international quality standards?

Of course. We follow strict quality management protocols and adhere to international standards to ensure that our products meet the requirements of various markets. Our production process includes rigorous testing and quality checks, giving customers confidence in the reliability and safety of our steel products.

What are SteelPRO Group's production capabilities?

With multiple efficient production lines, SteelPRO Group has a strong capacity to handle small and large orders. Our facilities are optimized for continuous output, allowing us to meet large volume demands while maintaining fast turnaround times.

CONTACT

Certificates and Cooperation

Certificates and Cooperation