TOOL STEEL BAR

Our tool steel bars are backed by a commitment to excellence and supported by streamlined logistics to ensure timely delivery, all at competitive rates.

Tool steel bars find extensive use in precision machining, toolmaking, die casting, and industrial machinery sectors, renowned for their exceptional hardness, wear resistance, and reliability under demanding conditions.

Contact us today to learn more and request a customized quote to meet your specific requirements.

What are Tool Steel Bars

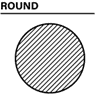

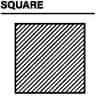

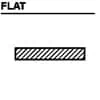

Tool Steel Bar Type

| Type | Size Ranges | Applications | |

|---|---|---|---|

| 1/4 inch to 12 inches diameter | Shafts for rotational applications | get a quote |

| 1/4 inch to 4 inches across flats | Tooling plates and dies | get a quote |

| 1/4 inch to 6 inches diameter | Nuts, bolts, and fittings | get a quote |

| 1/4 inch to 12 inches width, 1/8 inch to 6 inches thickness | Structural supports and frameworks | get a quote |

Tool Steel Bar Grades

| Standard | USA | SIZE | |

|---|---|---|---|

| AISI | D2 | 1/4" - 12" | get a quote |

| AISI | M2 | 1/8" - 6" | get a quote |

| AISI | A2 | 3/8" - 10" | get a quote |

| AISI | O1 | 1/8" - 8" | get a quote |

| AISI | S7 | 1/2" - 8" | get a quote |

| AISI | L6 | 5/8" - 10" | get a quote |

Quality Assurance for Tool Steel Bars

Regular Quality Inspections

- Microstructure Examination: Observing microscopic structure.

- Hardness Testing: Measuring hardness with Rockwell or Vickers testers.

- Heat Treatment Performance Testing: Assessing post-heat treatment performance.

- Chemical Composition Analysis: Analyzing composition using spectrometers or similar tools.

Extreme Testing

- Impact Toughness: Tests steel’s resistance using Charpy impact testers.

- High-Temperature Performance: Evaluates steel’s strength and hardness under heat.

- Fracture Toughness: Assesses steel’s ability to withstand fractures under extreme conditions.

- Fatigue Strength: Measures steel’s endurance under repetitive stress to assess fatigue life.

-

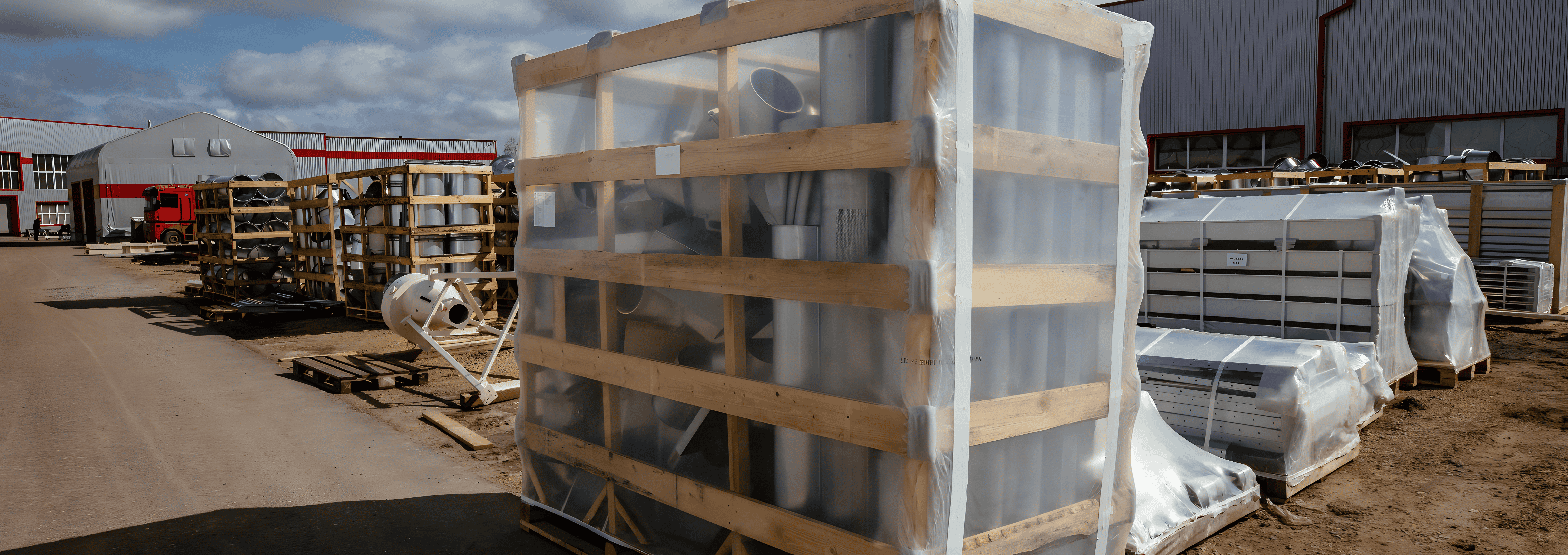

Secured Bundling: Bars are securely bundled with steel straps and wooden supports. Finished products are shipped in wooden crates.

-

Protective Coatings: Our steel bars are coated to prevent corrosion and damage during transit. Additional coating options are available upon request.

-

Labeling and Documentation: Each shipment is clearly labeled and comes with detailed documentation for easy tracking.

Tool steel bar performance is influenced by several key factors:

- Residual Stress: From machining and heat treatment, impacting stability.

- Chemical Composition: Carbon and alloy ratios affecting hardness and strength.

- Load Conditions: Static, dynamic, and impact stresses impacting performance.

- Storage and Transportation: Improper handling causing oxidation or damage.

- Cooling Conditions: Methods affecting performance in high-temperature environments.

Proper storage practices are essential to maintain the performance and longevity of tool steel bars.

- Environmental Control: Maintain stable temperatures to prevent thermal stress.

- Rust Prevention: Apply rust preventive oil or coatings on the surface.

- Avoid Direct Sunlight: Prevent elevated surface temperatures and performance degradation.

- Chemical Separation: Store away from chemicals to prevent corrosion.

- Dust Protection: Use dust covers or sealed containers to prevent dust accumulation.

Usage & Application of Tool Steel Bar

- Tool Manufacturing: Cutting tools, machine tooling, etc.

- Mold Manufacturing: Stamping dies, die-casting molds, injection molds, etc.

- Blade Manufacturing: Various types of blades and cutting tools.

- Cold Working Industry: Stamping, shearing, bending tools.

- Precision Measurement Tools: Gauges, instruments, precision tools.

- Weapons and Ammunition Manufacturing: Certain weapon and ammunition components.

Why Choose Our Tool Steel Bars

We offer high-quality tool steel bars crafted to exceed industry standards through meticulous craftsmanship and rigorous testing. Our commitment to comprehensive documentation ensures transparency and reliability in every transaction.

With competitive pricing, a diverse selection, and customizable options, supported by responsive service and efficient logistics, we cater to your specific needs with precision and reliability.

Choose us for structural steel bars that exceed industry standards and deliver exceptional results for your projects.