MN13 | Grade A | 10045-1 Abrasion Resistant Steel

MN13 | Grade A | 10045-1 Abrasion Resistant Steel

Mn13 is a high-manganese steel known for its wear resistance and toughness. “Mn” representing manganese and “13” indicating the manganese content percentage, designation indicates approximately 12-14% manganese. Originating in China, used in industries needing high abrasion resistance. Mn13 is similar to ASTM A128 Grade A and is also called Hadfield steel. Its ideal for mining and heavy machinery applications.

Description

What is Mn13?

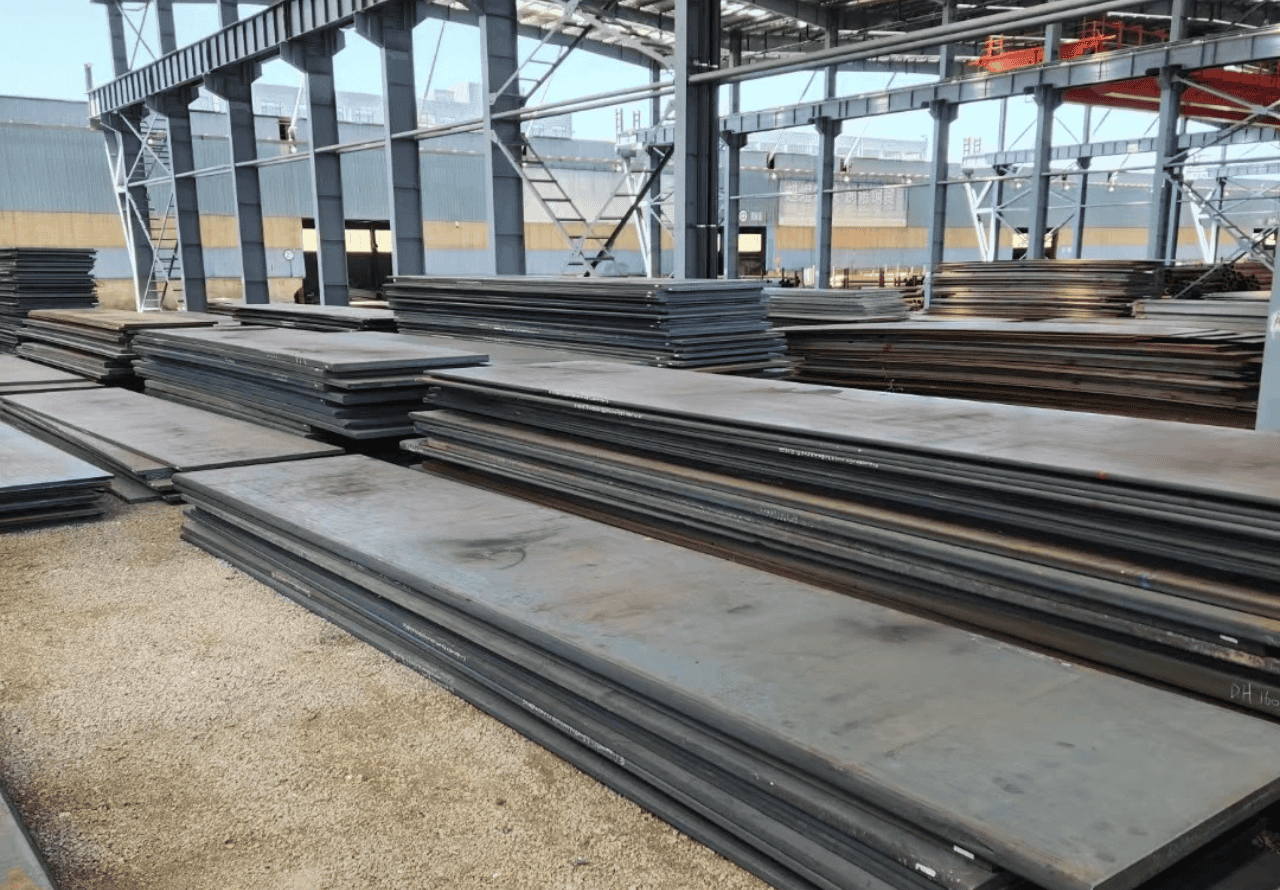

Mn13 is a high-manganese steel with approximately 12-14% manganese and the remainder iron. Typically available as plates or sheets, it is also an abrasion-resistant steel known for excellent wear resistance and impact toughness. Mn13 is used in mining, heavy machinery, construction equipment, and material handling. It is often used as-rolled but can be further processed through heat treatment or machining.Characteristics of Mn13 Steel

Mn13 steel is characterized by its high manganese content, typically ranging from 12-14%. This elevated manganese level enhances the steel’s wear resistance and impact toughness, making it ideal for abrasion-resistant components and hot-rolled steel plates. It is widely used in mining and heavy machinery applications due to its durability in harsh environments. Mn13 steel’s exceptional wear resistance extends the lifespan of components in abrasive conditions, while its impact resistance ensures it can withstand significant forces without cracking. It is also heat treatable, allowing further processing to enhance its properties. For applications requiring easier machining or processing, S235, S275, S355, or A36 structural steel grades may be more suitable alternatives.Chemical Compositions

| Element | Composition (%) |

|---|---|

| Manganese (Mn) | Approximately 12-14% |

| Carbon (C) | 1.0-1.4% |

| Silicon (Si) | 0.3-0.8% |

| Phosphorus (P) | Maximum 0.04% |

| Sulfur (S) | Maximum 0.04% |

| Iron (Fe) | Balance |

Physical Properties

| Physical Property | Metric | Imperial |

|---|---|---|

| Density | 7.8 g/cm³ | 0.28 lb/in³ |

| Melting Point | 1370-1400 °C | 2498-2552 °F |

| Boiling Point | – | – |

| Electrical Conductivity | – | – |

| Electrical Resistivity | – | – |

| Specific Heat Capacity | 500 J/kg·K | 0.12 BTU/lb·°F |

| Thermal Conductivity | 14.2 W/m·K | 8.2 BTU/ft·h·°F |

| Thermal Expansion Coefficient | 20.0 µm/m·K | 11.1 µin/in·°F |

Mechanical Properties

AC Properties of Mn13 Steel

| Property | Metric | Imperial |

|---|---|---|

| Tensile Strength | 800 MPa | 116 ksi |

| Yield Strength | 1,380 MPa | 200 ksi |

| Brinell Hardness | 350-400 HB | 350-400 HB |

| Rockwell Hardness | 55-60 HRC | 55-60 HRC |

| Vickers Hardness | 350-400 HV | 350-400 HV |

| Elongation | 35-50% | 35-50% |

| Elastic Modulus | 200 GPa | 29,000 ksi |

QT Properties of Mn13 Steel

| QT Properties | Metric | Imperial |

|---|---|---|

| Tensile Strength (Rm) | ≥ 952 MPa | ≥ 138.1 ksi |

| Yield Strength (Rp0.2) | ≥ 312 MPa | ≥ 45.2 ksi |

| Impact Toughness (KV/Ku) | 24 J | 17.7 ft-lb |

| Elongation (A) | ≥ 14% | ≥ 14% |

| Reduction in Area (Z) | 43% | 43% |

| Brinell Hardness (HBW) | 341 HBW | 341 HBW |

Industries & Applications

| Industries | Products |

|---|---|

| Mining | Crusher Liners, Excavator Buckets, Ball Mill Liners, Conveyor Chutes |

| Construction | Bulldozer Blades, Wear Plates, Dump Truck Liners, Excavator Teeth |

| Railway | Rail Clips, Track Pads, Rail Crossing Plates, Switch Components |

| Defense | Tank Tracks, Bulletproof Vests, Military Vehicles, Defense Barriers |

| Cement | Cement Mixer Liners, Kiln Parts, Clinker Crusher Hammers, Silo Liners |

| Power Generation | Coal Pulverizer Liners, Wind Turbine Components, Hydro Power Blades, Generator Components |

| Oil & Gas | Drill Pipe Protectors, Mud Pump Liners, Valve Seats, Pipeline Components |

| Automotive | Brake Drums, Chassis Components, Suspension Parts, Engine Mounts |

| Agriculture | Plow Blades, Harvester Components, Tractor Parts, Seed Drill Components |

Machining

Mn13 Heat Treatment Instructions

- Solution Treatment:

Heat to 1050-1100°C, hold, then rapidly cool (usually in water). Eliminates internal stress, improves toughness and ductility. - Aging Treatment:

Heat at 200-500°C for an extended period. Precipitation hardens to increase strength and hardness. - Quenching:

Heat to 900-1000°C, then rapidly cool. Significantly increases hardness and wear resistance, but may reduce toughness. - Tempering:

Reheat quenched steel to 200-600°C, then cool. Reduces brittleness, increases toughness and ductility. - Normalizing:

Heat above Ac3 or Ac4 (850-950°C), then air cool. Enhances mechanical properties and refines grain structure. - Annealing:

Heat above Ac1 (700-800°C), hold, then slowly cool. Reduces hardness, improves plasticity and toughness, relieves internal stress.

Mn13 Surface Finish

- Surface Hardening:

Includes flame and induction hardening. Rapid surface heating followed by cooling to harden and increase wear resistance. - Carburizing:

Heat in a carbon-rich environment at high temperature. Carbon diffuses into the surface, enhancing hardness and wear resistance. - Nitriding:

Heat in a nitrogen or ammonia atmosphere. Nitrogen atoms diffuse into the surface, forming a hard layer with improved hardness and corrosion resistance. - Carbonitriding:

Similar to carburizing but with nitrogen addition. Enhances surface hardness and wear resistance. - Electroplating:

Electrochemically deposit a metal layer (e.g., chromium, nickel) on the steel surface. Improves wear resistance, corrosion resistance, and appearance. - Thermal Spraying:

Apply a high-hardness, wear-resistant coating (e.g., aluminum oxide, tungsten carbide) using thermal spraying techniques.

Custom surface treatment requirements can be accommodated upon request.

Disclaimer

The above heat treatment instructions and surface finish processing methods for Mn13 steel are provided for informational purposes only. Actual results may vary based on specific conditions and equipment used. It is recommended to perform testing and consult with a metallurgical expert or the material supplier to ensure the processes are suitable for your specific application. The user assumes all risks and liability for the use of this information.

Our Service

SteelPRO Group – manufacturer and solution provider for special steel, offering multi-industry application solutions and customised services, 100% quality free, accompanying customers in their growth!

Our Quality Control

- Roundness

- Tolerance

- Microstructure

- Non-Destructive Testing

- Destructive Testing

- Process Control

Service Integration Processing

- Welding

- Metal Fabrication

- CNC Machining

- Lathe

- Forming

QUESTION 1

QUESTION 2

QUESTION 3

QUESTION 4

QUESTION 4

CONTACT

CONTACT

Certifications

Other Products

-

-

SteelPRO Group offers FH550 high-strength structural steel plates for shipbuilding....

-

SteelPRO Group offers DH550 high-strength shipbuilding steel plates in stock....

-

SteelPro Group offers FH36 high-strength steel for shipbuilding. It has...