DC01 Galvanized Steel Pipe | Tube

DC01 Galvanized Steel Pipe | Tube

SteelPRO Group is a manufacturer and supplier of DC01 galvanized steel pipes, supporting pipe cutting and forming, deep processing, and coating services. Our DC01 galvanized steel pipes are particularly suitable for applications that require high corrosion resistance and appearance, such as building structures, fluid transportation, HVAC piping systems, etc.

We also provide: square and rectangular tubes, galvanized seamless pipes, galvanized welded pipes, DC01 galvanized steel sheets/coils, DX51D, DX52D and other grades and forms of galvanized steel.

- Standards: EN 10305-3, EN 10255, EN 10346

- Grades: DC01, Q195, SPCC, AISI 1008, St12, SGCD1

- Technology: Hot Dip Galvanizing, cold rolling

- Certification: ISO 9001, CE

DC01 Galvanized Steel Pipe | Tube

DC01 Galvanized Steel Pipe | Tube

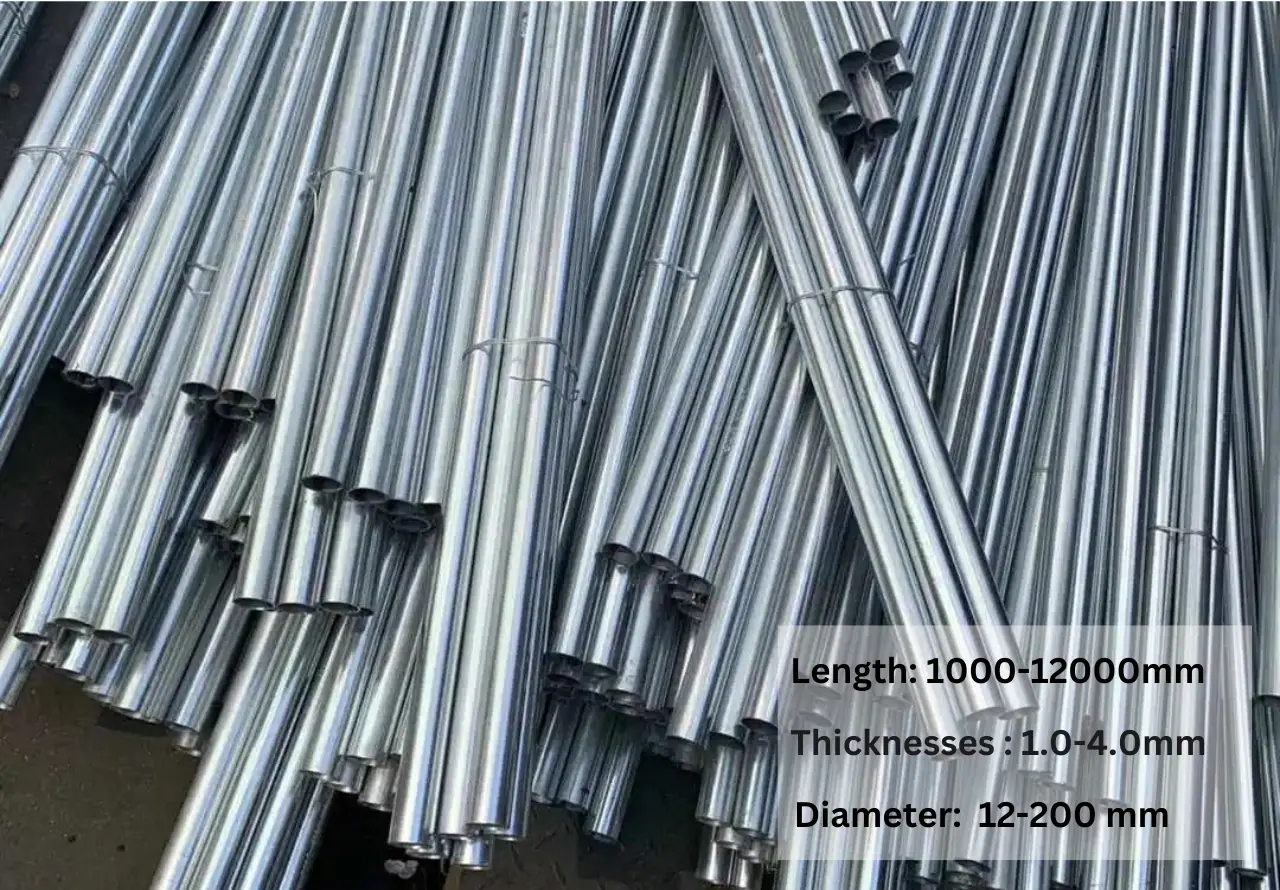

Product Specifications

Product Specifications

| Product Name | DC01 Hot Dip Galvanized Steel Pipe & Tube |

| WT (Wall Thickness) | 1mm – 4mm, Customized |

| OD (Outer Diameter) | 12mm – 200mm, Customized |

| Length | 1000mm – 12000mm, Customized |

| Zinc Coating | 20-400g/m², g30, g40, g60, g90, etc. |

| Surface Treatment | Anti-finger print / Skin pass / Oiled / Dry / Chromated / Embossed / Lamination |

| Spangle | Zero Spangle / Mini Spangle / Regular Spangle / Large Spangle |

| Pipe ends | Smooth end / Threaded end / With connector |

| Test | Zinc Coating Thickness Test, Salt Spray Test, Adhesion Test, Tensile Test, Impact Test, Bend Test, Welding Test, etc. |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Invoicing | By actual weight |

| Delivery Time | 7-15 days |

| Payment | T/T, L/C, Credit Card |

| Port | Shanghai, Qingdao or according to your requirement |

| Packaging Details | In bundles, in bulk, customized packing |

Chemical Compositions

Chemical Compositions

| Element | Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon (Si) |

|---|---|---|---|---|---|

| Content (Max, %) | 0.12 | 0.6 | 0.045 | 0.045 | 0.03 |

Mechanical properties

Mechanical properties

| Property | DC01 Galvanized Steel Pipe |

|---|---|

| Tensile Strength (MPa) | 270-410 |

| Yield Strength (MPa) | 140-280 |

| Elongation (%) | 28 (min) |

| Hardness (Brinell) | 85 (max) |

| Hardness (Rockwell B) | 50-70 |

| Hardness (Vickers) | 100-140 |

| Modulus of Elasticity (GPa) | 210 |

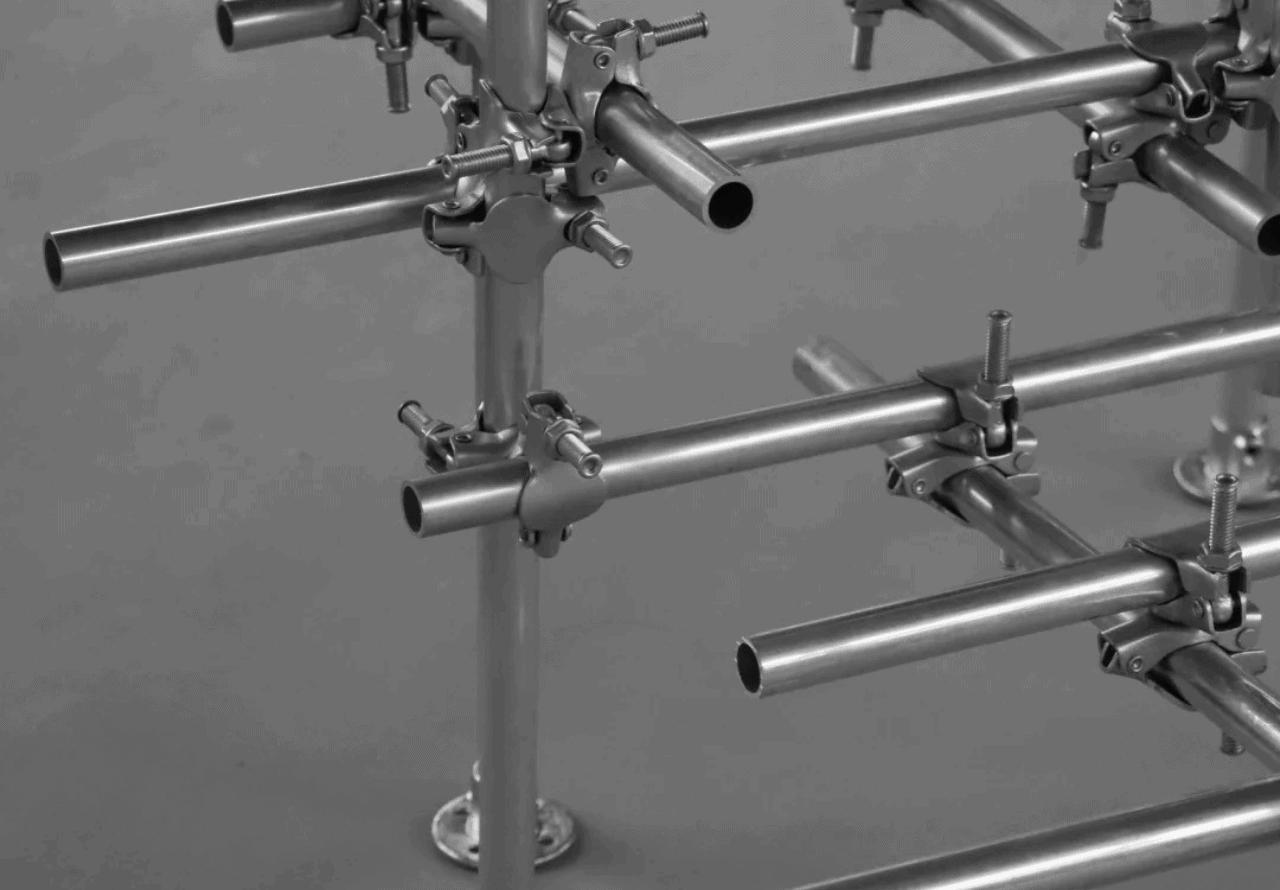

Industries & Applications

Industries & Applications

DC01 galvanized steel pipe is widely used in the following industries due to its good corrosion resistance and mechanical strength:

- Building and construction: used for frame structures, guardrails, drainage systems, etc., suitable for outdoor use.

- HVAC: used for heating, ventilation and water supply pipes, corrosion-resistant and durable.

- Automobile manufacturing: used for exhaust systems and frame components to improve durability.

- Home appliance industry: used for housings and supporting components of home appliances such as air conditioners and refrigerators.

- Energy and power: used for cable protection pipes and brackets for new energy equipment.

- Agriculture and greenhouses: suitable for greenhouse structures and agricultural drainage systems.

- Fluid transportation: suitable for oil, natural gas and water supply pipelines.

Other Infomation

Other Infomation

Why choose DC01 Gi Pipe?

- Corrosion Resistance: High corrosion resistance due to zinc coating.

- Formability: Excellent for bending, stamping, and cutting.

- Weldability: Suitable for high-frequency and gas welding.

- Oxidation Resistance: Strong resistance, ideal for outdoor use.

- Pressure Resistance: Medium resistance, great for structural support and fluid transport.

- Surface Quality: Smooth and uniform, good for decorative applications.

- Environmental Performance: Recyclable and eco-friendly.

Our Inventory

Our Inventory

As a professional steel supplier and manufacturer, SteelPRO Group is committed to becoming a trusted partner of customers through high-quality products and quick response. We strictly control quality, with an annual production capacity of more than 1 million tons, efficient delivery, and customized services. Our products meet international standards and meet the diverse needs of customers.

Main products: steel pipes, steel plates, steel coils, steel bars, steel strips, stainless steel series, carbon steel series, high-strength steel series, nuclear grade steel, galvanized steel, steel for wind and solar energy, etc.

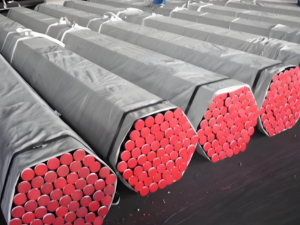

Packing

Packing

We take the following measures when transporting and packaging DC01 galvanized steel pipes:

- Protective packaging: Use moisture-proof materials and plastic sheets to wrap the steel pipes to prevent moisture and corrosion during transportation.

- Secure bundling: Use steel straps and pallets to firmly bundle the steel pipes to prevent movement and collision during transportation.

- Soft cushion protection: Add soft cushions between steel pipes to prevent damage to the surface galvanized layer caused by friction.

- Clear labeling: Mark the specifications and quantities for each batch of products to ensure accurate delivery.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

Do you offer custom sizes and coatings?

Yes, we offer custom galvanized steel products based on your specific needs, including different sizes, thicknesses, and coating options (galvanized or pre-painted finishes).

What types of galvanized steel products do you offer?

We offer galvanized steel sheets, coils, and pipes in both hot-dip and electro-galvanized options. We also offer pre-painted galvanized steel (PPGI) for applications that require an aesthetic finish and extra protection.

How do you ensure the quality of galvanized steel?

We follow strict quality control procedures throughout the manufacturing process. Our galvanized steel products comply with international standards such as ASTM, EN and JIS, and we conduct regular tests to ensure that they meet customer specifications for strength, coating thickness and durability.

Do you provide a delivery service? How long is the delivery time?

Yes, we provide a reliable delivery service to ensure that your products arrive on time. Delivery times vary depending on the product and order size, but we strive to complete delivery of most orders within 2 to 4 weeks. Expedited service is available upon request.

How long is the service life of galvanized steel?

The service life of galvanized steel depends on the environment. In non-corrosive environments, galvanized steel can last up to 50 years, while in more corrosive environments, galvanized steel will still provide excellent protection for 20-25 years.

What is your minimum order quantity (MOQ) for galvanized steel products?

Our minimum order quantity (MOQ) varies depending on the specific product and customization requirements. Generally, we can accept both small and large orders. Please contact our sales team for details on the specific MOQ based on your needs.

CONTACT

Certificates and Cooperation

Certificates and Cooperation