SECC | SECD | SECE Electro Galvanized Steel Sheet & Coil

SECC | SECD | SECE Electro Galvanized Steel Sheet & Coil

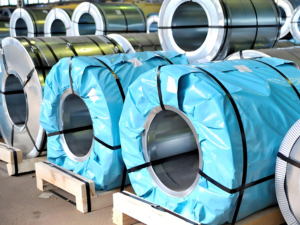

SteelPRO Group is a supplier of SECC, SECE and SECD electrogalvanized steel sheets and coil to meet a variety of needs. Our products are available in various forming grades (A, B, C, H) to ensure flexibility and performance for various applications. We offer specialized surface treatments such as anti-fingerprint, phosphating, chromate-free and UV-resistant to meet different environmental and aesthetic requirements. SteelPRO Group is committed to providing quality, customization and reliable services, and also has various grades of plates, coils, tubes, PPGI, roofing sheets.

- Standard: JIS G3313

- Grades: SECC, SECD, SECE, DX56D+Z

- Technology: Electrogalvanizing, passivation treatment, deep drawing, cold rolling

- Base material: SPCC, SPCD, SPCE

- Certification: ISO, TUV, SGS, BIS, CE

SECC | SECD | SECE Electro Galvanized Steel Sheet & Coil

SECC | SECD | SECE Electro Galvanized Steel Sheet & Coil

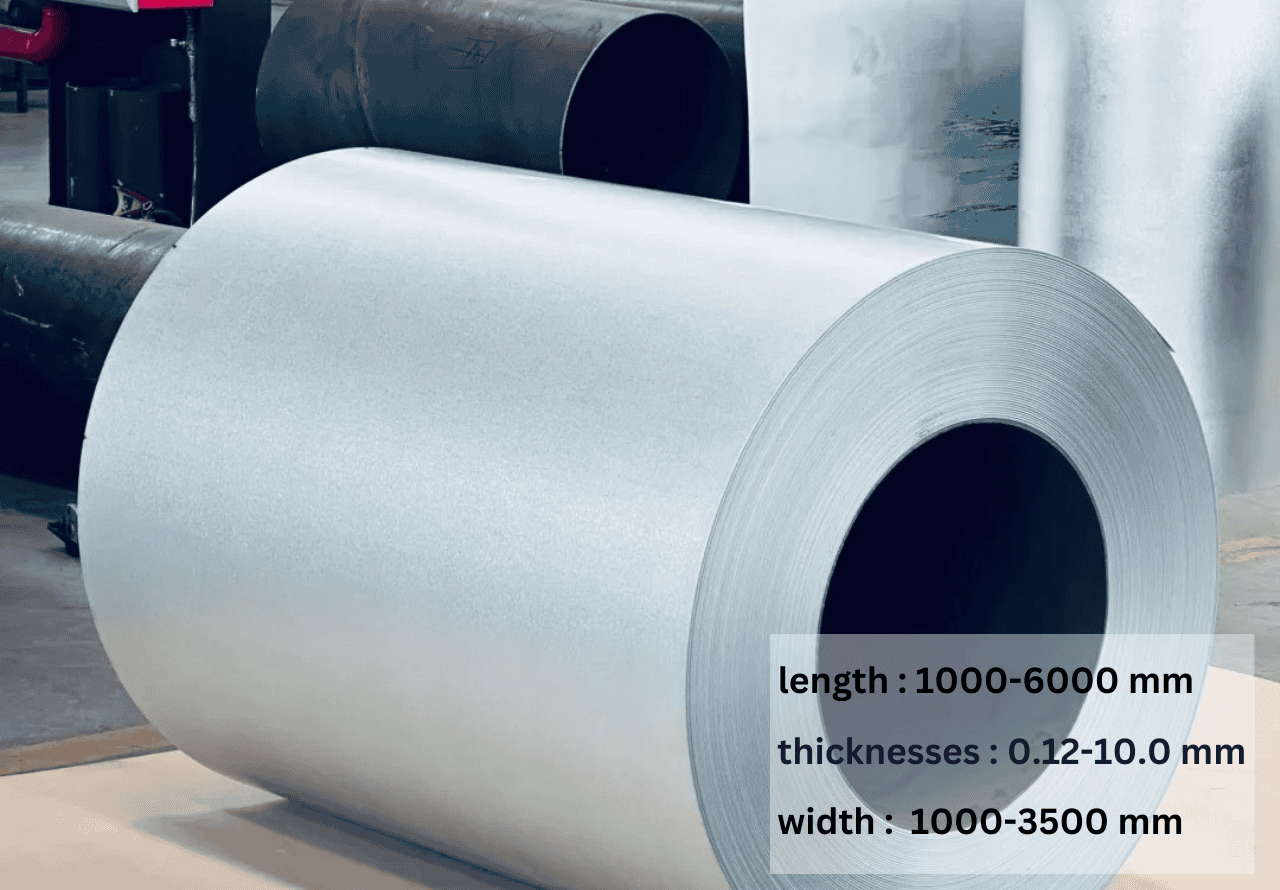

Product Specifications

Product Specifications

| Product Name | SECC | SECD | SECE Electro Galvanized Steel Sheet & Coil |

| Thickness | 0.12mm – 10.0mm, Customized |

| Width | Regular: 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, Customized |

| Length | 1000mm – 6000mm, Customized |

| Coil ID | 508mm/610mm |

| Zinc Coating | 20-400g/m², g30, g40, g60, g90, Z20-Z29, Z81-Z120, etc. |

| Surface Treatment | Anti-finger print / Skin pass / Oiled / Dry / Chromated / Embossed / Lamination |

| Spangle | Zero Spangle / Mini Spangle / Regular Spangle / Large Spangle |

| Edge | Mill edge, Cut edge |

| Hardness | Soft Hard(<60)

Medium Hard(60-85) Full Hard(85-95) |

| Test | Zinc Coating Thickness Test, Salt Spray Test, Adhesion Test, Tensile Test, Bend Test, Cross-hatch, etc. |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Invoicing | By actual weight |

| Delivery Time | 7-15 days |

| Payment | T/T, L/C, Credit Card |

| Port | Shanghai, Qingdao or according to your requirement |

| Packaging Details | In bundles, in bulk, customized packing |

Chemical Compositions

Chemical Compositions

| Element | Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon (Si) |

|---|---|---|---|---|---|

| Composition (%) | ≤ 0.15 | ≤ 0.60 | ≤ 0.05 | ≤ 0.05 | ≤ 0.03 |

Mechanical properties

Mechanical properties

| Property | Typical Value |

|---|---|

| Tensile Strength (MPa) | 270 – 410 |

| Yield Strength (MPa) | 140 – 280 |

| Elongation (%) | ≥ 28 |

| Vickers Hardness (HV) | 80 – 120 |

| Brinell Hardness (HB) | 70 – 100 |

| Rockwell Hardness (HRB) | 55 – 75 |

| Elastic Modulus (GPa) | Approximately 210 |

Industries & Applications

Industries & Applications

SECC (Standard Commercial Quality)

- Household Appliance Housing: Widely used in the housings of household appliances such as refrigerators, washing machines, and air conditioners, providing corrosion protection and beautiful surfaces.

- Office Equipment: Suitable for housings of equipment such as printers, copiers, and computer cases that require basic forming and structural strength.

- Building Materials: Used in building materials and internal frames for lightweight structures, with basic protection and formability.

- Hardware Products: Suitable for general hardware structural parts, such as small brackets, tool boxes, etc., with good processing performance.

SECE (Enhanced Formability Quality)

- Automotive Interior Parts: Used for complex formed parts in automotive interiors, such as instrument panel brackets, door panel linings, etc., with excellent formability and ductility.

- Electronic Equipment Housing: Suitable for making complex electronic equipment housings, such as tablet and smartphone housings, ensuring smooth appearance and easy processing.

- Precision Small Parts: Widely used in precision parts that require high ductility, such as connectors and small sheet metal parts, especially in bending and stamping processes.

- High-end home appliances: Suitable for home appliances with high requirements on appearance, such as high-end kitchen appliances and small appliances, providing high-quality surface treatment and corrosion resistance.

SECD (Deep Drawing Quality)

- Automobile fuel tanks and fuel systems: Commonly used for complex-shaped parts in automobile fuel tanks and fuel systems, adapting to the high requirements of deep drawing forming.

- Complex metal shells: Suitable for metal shells that require deep drawing processes, such as industrial equipment shells, heavy machinery protective covers, etc.

- Containers and metal cans: Suitable for the manufacture of metal cans and containers for food and beverages, ensuring uniform thickness and excellent protective performance after deep drawing.

- Home appliance structural parts: Complex structural parts used in home appliance products, such as washing machine drums and air conditioning compressor shells, requiring high plasticity and durability.

Other Infomation

Other Infomation

If you are struggling to choose between hot-dip galvanized steel and electro-galvanized steel, you can refer to the following information or contact us for professional advice.

Hot-dip galvanized steel: The zinc layer is thicker, suitable for outdoor and highly corrosive environments, such as bridges and outdoor buildings, and can provide longer anti-corrosion protection under harsh conditions. At the same time, the coating has strong adhesion and toughness, and can withstand a greater degree of impact and damage during transportation and use.

Electro-galvanized steel: The zinc layer is thinner and the surface is smooth, suitable for indoor or appearance-oriented applications, such as home appliances and electronic product casings. It has better processability and is suitable for bending and stamping, but its corrosion resistance in harsh environments is not as good as hot-dip galvanizing.

On SECC, SECD and SECE electrogalvanized steels, we often see some letter suffixes, such as -N, -P, etc. Each suffix represents a special surface treatment or use, specifically:

- -N: Fingerprint-resistant, can prevent fingerprint residue, suitable for home appliance housings and electronic devices.

- -P: Phosphating treatment, enhanced corrosion protection and coating adhesion, commonly used in automobiles and outdoor equipment.

- -AF: Stronger anti-fingerprint effect than -N, suitable for high-end home appliance housings.

- -CF: Chromium-free treatment, suitable for products with high environmental protection requirements or export.

- -O: Oiling treatment, short-term rust prevention, suitable for transportation and storage protection.

- -CZ: High temperature resistant treatment, suitable for heating components of electrical appliances.

- -UV: UV resistant, suitable for long-term outdoor exposure.

Our Inventory

Our Inventory

When you choose SteelPRO Group, a galvanized steel manufacturer, you will benefit from our strong production capabilities and industry reputation. We have established long-term relationships with well-known global partners to ensure that our product quality and technology are always at the forefront of the industry. Our production base is equipped with multiple modern production lines with efficient and flexible production capacity to meet diverse needs, ensuring rapid response and stable supply. This strong supply chain capability enables us to provide customers with a reliable delivery experience, whether it is during peak demand periods or special specifications, and always maintain high-quality service.

Main products: steel pipes, steel plates, steel coils, steel bars, steel strips, stainless steel series, carbon steel series, high-strength steel series, nuclear grade steel, galvanized steel, steel for wind and solar energy, etc.

Packing

Packing

Our packaging is strictly carried out in accordance with international standards to ensure the safety and integrity of the products during transportation. Each batch of steel is packaged in a moisture-proof and rust-proof manner, and is equipped with a strong edge protection to ensure that the products are protected from collision or extrusion. We also provide personalized packaging options to meet the special needs of different customers, ensuring that the products are always in the best condition from the factory to your hands.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

What specific applications are SECC, SECE and SECD steel sheets suitable for?

SECC is suitable for home appliance housings and structural parts, SECE is designed for complex forming needs and is widely used in automotive interiors and electronic equipment housings, while SECD is suitable for deep drawing applications such as automotive fuel tanks and metal containers.

What are the surface treatment options for these electrogalvanized steel sheets?

We provide surface treatment options including fingerprint resistance, phosphating, chrome-free and environmentally friendly to meet customers’ different needs for corrosion resistance, environmental protection and aesthetics.

Is electrogalvanized steel sheet easy to form during processing?

Yes, SECC, SECE and SECD have good processing performance. SECC is suitable for general forming, SECE is suitable for more complex forming, and SECD is designed for deep drawing to reduce the risk of processing cracks.

What are the advantages of SteelPRO Group in the production of electrogalvanized steel sheets?

With many years of production experience and advanced equipment, SteelPRO Group ensures the high quality and consistency of each batch of steel. We also provide customized services to meet customers’ specific needs.

What support and after-sales service does SteelPRO Group provide?

We provide comprehensive pre-sales consultation and after-sales technical support to ensure that customers’ application needs are met and provide necessary technical information and product recommendations.

Do SteelPRO Group's products meet international quality standards?

Yes, all our products comply with international standards (such as JIS, ASTM and EN) and pass strict quality inspections to ensure high quality and reliability.

CONTACT

Certificates and Cooperation

Certificates and Cooperation