ALLOY STEEL BAR

We use advanced processes to deliver superior low-alloy, medium-alloy, and high-alloy steel bars. Low-alloy bars offer strength for automotive and construction machinery, medium-alloy bars provide hardness for industrial tools, and high-alloy bars deliver corrosion resistance for aerospace and chemical industries.

We offer competitive pricing and high quality for cost-effective solutions. Our efficient production and logistics ensure rapid, reliable delivery.

Choose our alloy steel bars for exceptional quality, versatile applications, and outstanding service.

What are Alloy Steel Bars

Alloy Steel Bar Type

| Type | Size Ranges | Applications | |

|---|---|---|---|

| Diameter from 0.2 inches to 12 inches | For shafts, axles, pins, structural components | get a quote |

| Across flats from 0.24 inches to 4 inches | Used in structural beams | get a quote |

| Side length from 0.2 inches to 6 inches | For fasteners, equipment, ornamental ironwork | get a quote |

| Thickness 0.08 inches to 4 inches Width 0.4 inches to 12 inches | Ideal for base plates, brackets, braces | get a quote |

Alloy Steel Bar Grades

| Standard | USA | SIZE | |

|---|---|---|---|

| ASTM A29 | AISI 4130 | 1/4'' - 10'' | get a quote |

| ASTM A29 | AISI 4140 | 1/4'' - 10'' | get a quote |

| ASTM A29 | AISI 4145 MOD | 1/2'' - 8'' | get a quote |

| ASTM A29 | AISI 8620 | 1/4'' - 8'' | get a quote |

| ASTM A29 | AISI 4340 | 1/4'' - 10'' | get a quote |

| ASTM A29 | AISI 8720 | 1/4'' - 8'' | get a quote |

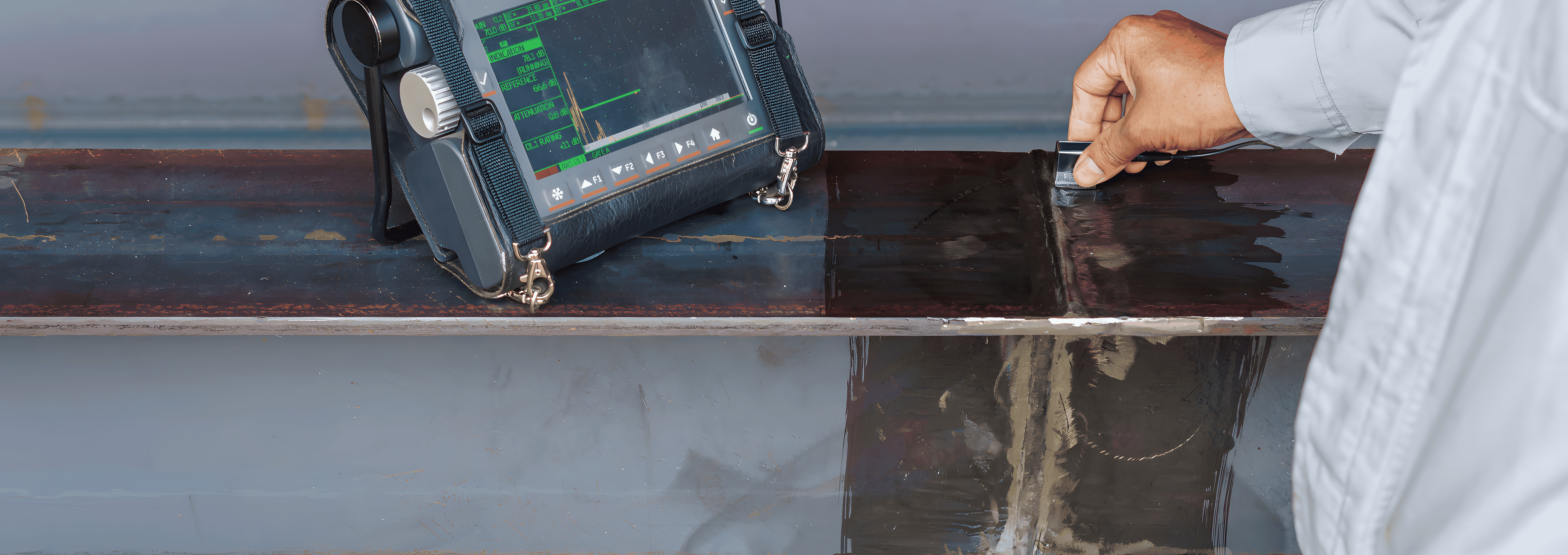

Quality Assurance for Alloy Steel Bars

Regular Quality Inspections:

- Dimensional Accuracy: Ensuring precise measurements of diameter, thickness, and length.

- Surface Finish: Checking for smoothness and absence of defects such as cracks or scales.

- Mechanical Properties: Testing tensile strength, yield strength, and hardness.

- Chemical Composition: Verifying the correct alloy mix through spectroscopic analysis.

Extreme Testing:

- Fatigue Testing: Determining the bar’s endurance limit under repeated stress cycles.

- Corrosion Resistance: Exposing the bars to corrosive environments to test durability.

- Temperature Resistance: Testing bars under extreme temperatures.

- Bending and Flexural Testing: Assessing bars’ ability to withstand bending forces.

If you have specific requirements, we can customize additional tests to meet your needs.

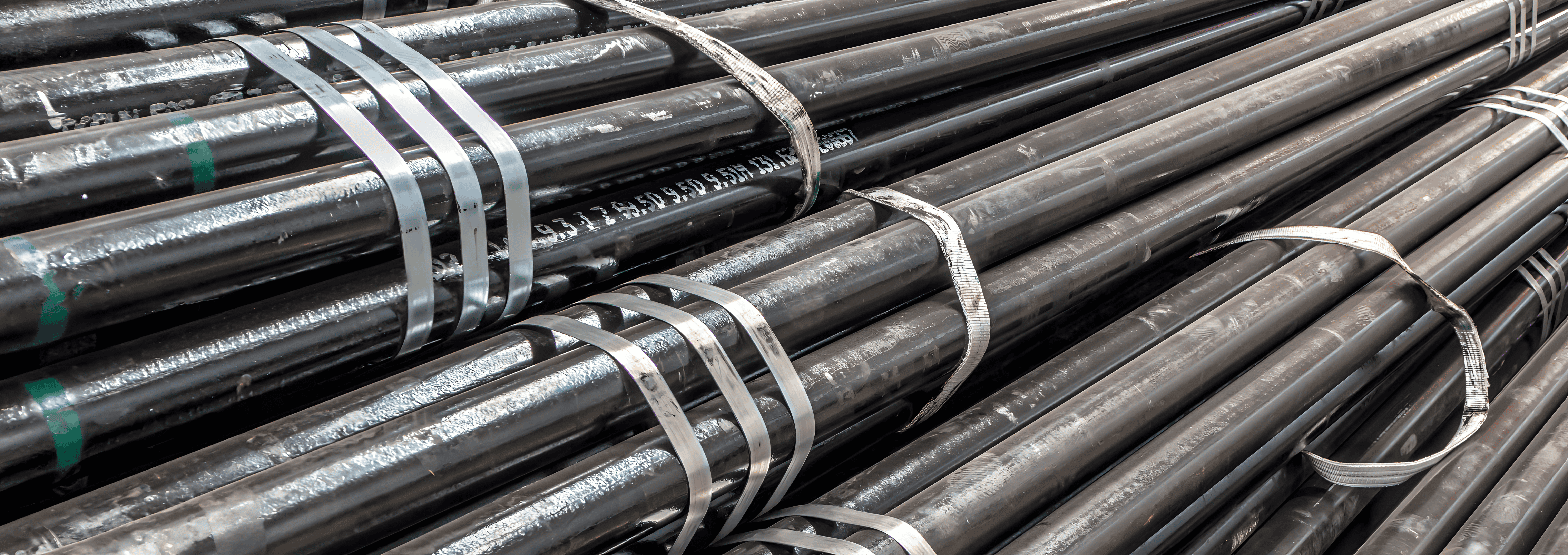

To ensure the safe and secure transportation of our steel bars, we use robust packaging methods:

-

Secured Bundling: Bars are securely bundled with steel straps and wooden supports. Finished products are shipped in wooden crates.

-

Protective Coatings: Our steel bars are coated to prevent corrosion and damage during transit. Additional coating options are available upon request.

-

Labeling and Documentation: Each shipment is clearly labeled and comes with detailed documentation for easy tracking.

Environmental and transportation factors play a crucial role in determining the performance of alloy steel bars. Proper handling and storage are essential to maintain their quality.

- Environmental Exposure: Protect from moisture and corrosive environments to prevent rust.

- Temperature Fluctuations: Avoid extreme temperature changes to prevent thermal stress and deformation.

- Handling: Use appropriate lifting equipment to prevent bending or warping.

- Transportation: Secure bars properly during transit to avoid damage from impacts and abrasion.

Proper storage of alloy steel bars is vital to maintain their quality and performance. External factors like environment and transportation can significantly affect these bars.

- Dry Environment: Store in a dry, ventilated area to prevent rust.

- Stable Temperature: Maintain stable temperatures to avoid thermal stress.

- Humidity Control: Use dehumidifiers or desiccants.

- Proper Packaging: Use appropriate packaging to prevent transit damage.

- Safe Handling: Use proper lifting equipment to avoid bending.

Certain alloy steels can become brittle in low temperatures. Use insulation or heating devices to prevent exposure to extremely low temperatures.

Usage & Application of Alloy Steel Bar

Alloy steel bars are essential across various industries due to their enhanced properties. These bars provide superior strength, hardness, and corrosion resistance, making them suitable for demanding applications.

- Automotive Industry: Engine components and transmission parts.

- Construction Industry: Structural beams and reinforcement.

- Machinery Manufacturing: Gears, shafts, and high-stress parts.

- Aerospace Industry: Landing gear and structural components.

- Oil and Gas Industry: Drilling equipment and pipelines.

- Agricultural Machinery: Parts for tractors and harvesters.

Why Choose Our Alloy Steel Bars

Choose our alloy steel bars for their superior quality and strength, backed by comprehensive documentation for reliability and traceability. We provide a wide selection, customization options, and competitive pricing. Our bars deliver top performance in demanding applications, ensuring the best value for your investment.

Additionally, our commitment to timely delivery and responsive service ensures that you receive your orders promptly and with full support. We pride ourselves on providing a seamless purchasing experience, from initial inquiry to final delivery.

Trust us for alloy steel bars that combine top-notch quality, extensive customization options, and excellent customer service.