DC01 | Q195 Galvanized Steel sheet

DC01 | Q195 Galvanized Steel sheet

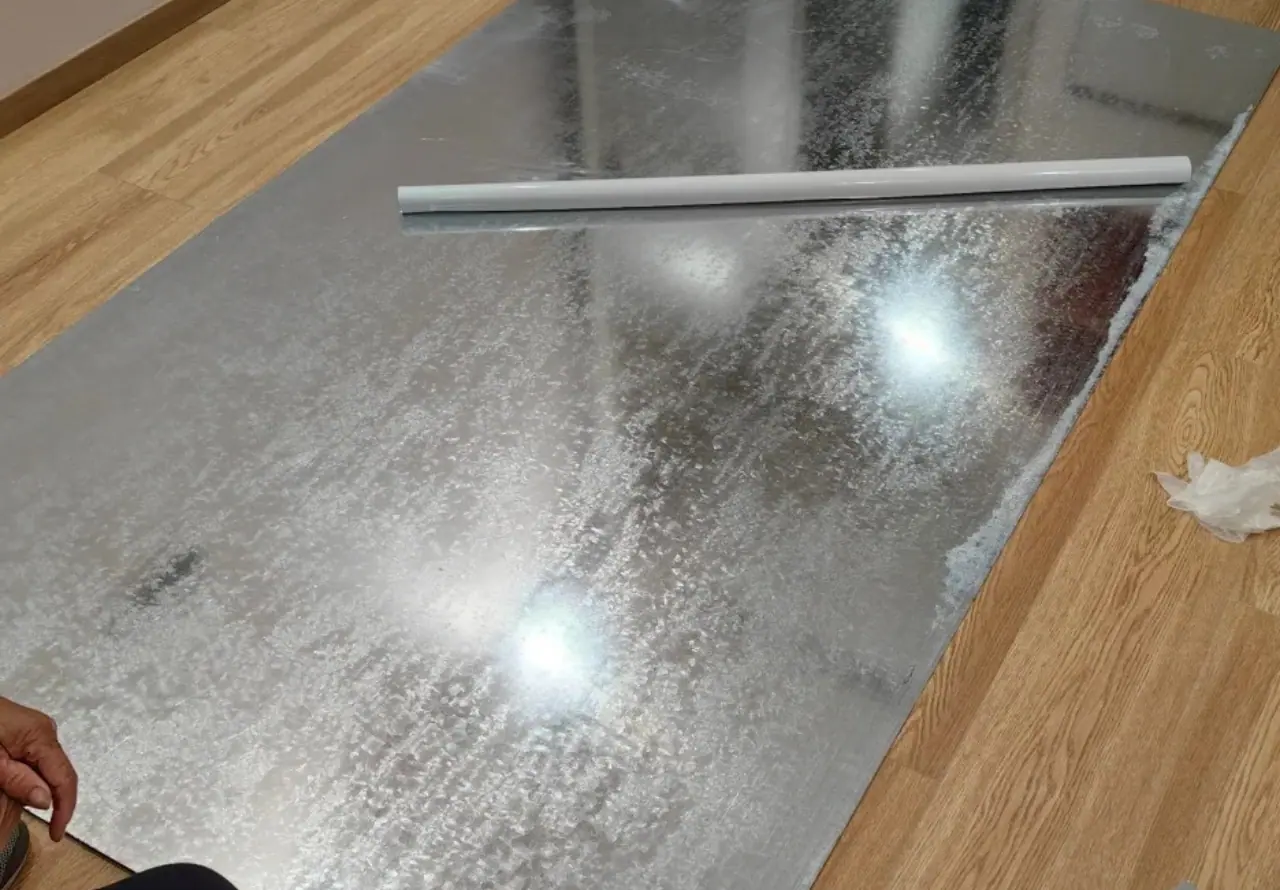

SteelPRO Group is a professional manufacturer and supplier of DC01 and Q195 galvanized steel sheets, providing you with high-quality DC01 and Q195 galvanized steel sheets suitable for barrel containers, refrigerators, washing machines, auto parts, decoration, piping systems, etc. We also provide products such as DC01Gi Coil, DX51D Gi plate & coil, PPGI sheet, as well as value-added services such as customized galvanizing thickness and shearing processing.

- Standard: EN 10346, EN 10130, GB/T 2518, JIS G 3141, ASTM A663

- Grades: DC01, Q195, SPCC, AISI 1008, St12, SGCD1

- Technology: Hot Dip Galvanizing, cold rolling

- Substrate: DC01 Cold rolled sheet, Q195 Cold rolled sheet

- Certification: ISO 9001, CE

DC01 | Q195 Galvanized Steel sheet

DC01 | Q195 Galvanized Steel sheet

Product Specifications

Product Specifications

| Product Name | DC01 | Q195 Hot Dip Galvanized Steel Sheet |

| Thickness | 0.3mm – 3.0mm, Customized |

| Width | 600mm – 1500mm, Customized |

| Length | 1000mm – 6000mm, Customized |

| Zinc Coating | 20-400g/m², g30, g40, g60, g90, etc. |

| Surface Treatment | Anti-finger print / Skin pass / Oiled / Dry / Chromated / Embossed / Lamination |

| Spangle | Zero Spangle / Mini Spangle / Regular Spangle / Large Spangle |

| Edge | Mill edge, Cut edge |

| Test method | Zinc Coating Thickness Test, Salt Spray Test, Adhesion Test, Tensile Test, Bend Test, etc. |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Invoicing | By actual weight |

| Delivery Time | 7-15 days |

| Payment | T/T, L/C, Credit Card |

| Port | Shanghai, Qingdao or according to your requirement |

| Packaging Details | In bundles, in bulk, customized packing |

Chemical Compositions

Chemical Compositions

| Element | DC01 Gi Sheet (Max, %) | Q195 Gi Sheet (Max, %) |

|---|---|---|

| Carbon (C) | 0.12 | 0.12 |

| Manganese (Mn) | 0.6 | 0.5 |

| Phosphorus (P) | 0.045 | 0.045 |

| Sulfur (S) | 0.045 | 0.05 |

| Silicon (Si) | 0.03 | 0.03 |

Mechanical properties

Mechanical properties

| Property | DC01 Gi Sheet | Q195 Gi Sheet |

|---|---|---|

| Yield Strength (MPa) | 140-280 | 195 (min) |

| Tensile Strength (MPa) | 270-410 | 315-430 |

| Elongation (%) | 28 (min) | 33 (min) |

| Hardness (Brinell) | 85 (max) | 90-110 |

| Hardness (Rockwell B) | 50-70 | 55-75 |

| Hardness (Vickers) | 100-140 | 120-160 |

| Modulus of Elasticity (GPa) | 210 | 205 |

Industries & Applications

Industries & Applications

DC01 Galvanized Steel Sheet Applications

- Automotive industry: Used for manufacturing car body panels, interior parts, and structural components due to its excellent formability and surface finish.

- Home appliances: Ideal for making washing machine bodies, refrigerator panels, and air conditioning units, offering corrosion resistance and easy post-processing.

- Construction: Commonly used in roofing, wall panels, and partition systems, providing both structural support and protection from environmental elements.

- Electrical enclosures: Suitable for fabricating control panels, switchgear, and other electrical housing due to its durability and protective zinc coating.

- Furniture: Often used for manufacturing durable, corrosion-resistant metal furniture, especially for outdoor applications.

Q195 Galvanized Steel Sheet Applications

- Building materials: Used in the production of steel pipes, structural elements, and roofing materials due to its higher strength and flexibility.

- Wire products: Ideal for making galvanized wires, mesh, and nails, where both strength and rust resistance are critical.

- Pipelines: Commonly used in water and gas pipelines due to its good mechanical properties and corrosion resistance.

- Automotive parts: Utilized in the production of parts requiring moderate strength and corrosion protection, such as exhaust systems.

- Machinery components: Used in the production of small mechanical parts and components due to its ability to withstand moderate loads and stresses.

Other Infomation

Other Infomation

The thickness of the zinc coating is one of the key factors that determine the service life of the galvanized steel sheet. You can choose the appropriate zinc coating according to your actual needs. The estimated service life of the common zinc coating thickness in ordinary urban construction environments is as follows:

- G30 (90g/m²): about 5-10 years

- G40 (120g/m²): about 10-15 years

- G60 (180g/m²): about 15-20 years

- G90 / Z275 (275g/m²): about 20-30 years

- Z100 (100g/m²): about 10-15 years

- Z350 (350g/m²): about 40 years or more

- Dry indoor environment (such as indoor building structures, office furniture): 20-30 µm

- Moderate outdoor environment (such as suburbs, low pollution areas): 50-60 µm

- Urban or light industrial environment (moderate pollution, moderate humidity): 70-80 µm

- High humidity or heavy industrial environment (such as chemical plants, acid gas areas): 85-100 µm

- Coastal areas (strong salt spray, high corrosion): 100-150 µm

- Marine environment (strong corrosion, such as offshore facilities, port equipment): 150 µm and above

Our Inventory

Our Inventory

As a professional steel supplier and manufacturer, SteelPRO Group is committed to becoming a trusted partner of customers through high-quality products and quick response. We strictly control quality, with an annual production capacity of more than 1 million tons, efficient delivery, and customized services. Our products meet international standards and meet the diverse needs of customers.

Main products: steel pipes, steel plates, steel coils, steel bars, steel strips, stainless steel series, carbon steel series, high-strength steel series, nuclear grade steel, galvanized steel, steel for wind and solar energy, etc.

Packing

Packing

As a professional galvanized steel supplier, we take the following measures during transportation and packaging to maintain the excellent anti-corrosion performance and appearance quality of galvanized steel.

- Protective packaging: Use waterproof plastic cloth and moisture-proof materials to package galvanized steel to prevent the zinc layer from getting damp or corroded during transportation.

- Surface protection: To prevent the galvanized layer from being scratched or damaged during transportation, we add soft pads or protective films on the surface of the steel.

- Stable loading: Use pallets, steel strapping and other methods to ensure that the galvanized steel is stable during transportation without shifting or collision.

- Clear identification: Each batch of galvanized steel has detailed specifications, quantities and order labels to ensure fast and accurate delivery.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

Can I visit your factory?

Of course, you are welcome to visit our factory. Please contact us in advance so that we can arrange a suitable visit time for you. We will do our best to guide you and ensure that your visit experience is both fulfilling and enjoyable.

What are your advantages?

Honest management, competitive prices, diverse products, large production capacity, and professional services during the export process.

Can you tailor products to our specifications?

Yes, simply inform us of your requirements, and we can provide customized solutions, encompassing material, hardness, thickness, width, and other specifications.

Do you accept third-party inspections?

Yes, we absolutely accept.

Do you provide samples? Free or additional?

Yes, we can provide free samples for quality evaluation. However, the freight is usually borne by your company.

Are the products quality checked before loading?

Yes, all our products must pass three inspections throughout the manufacturing process, including production and warehouse random testing, and unqualified products will be destroyed before shipment.

CONTACT

Certificates and Cooperation

Certificates and Cooperation