A242 | Weathering Steel

A242 | Weathering Steel

A242 Weathering Steel is a high-strength, low-alloy steel designed to resist atmospheric corrosion. “A242” refers to its ASTM standard. It forms a protective rust layer when exposed to the elements, reducing the need for painting. A242 offers durability, toughness, weldability, and is used in bridges, buildings, and outdoor structures. Equivalent grades include E36WA4, S355J2WP, and A588.

Description

What is A242?

A242 is a low-alloy steel made of 0.25-0.55% copper and 0.20-0.50% chromium. It comes in solid plates or sections and resists corrosion. When exposed to air, it forms a protective iron oxide layer, reducing the need for paint. It is processed through hot rolling and used in outdoor structures like bridges and buildings.Why Choose A242 Weathering Steel?

Product Specification

| Category | Details |

| Quality Standard | ASTM A242/A242M |

| Certifications | ASTM G101, ISO 9001, EN 10025 S355J2WP, BV, SGS |

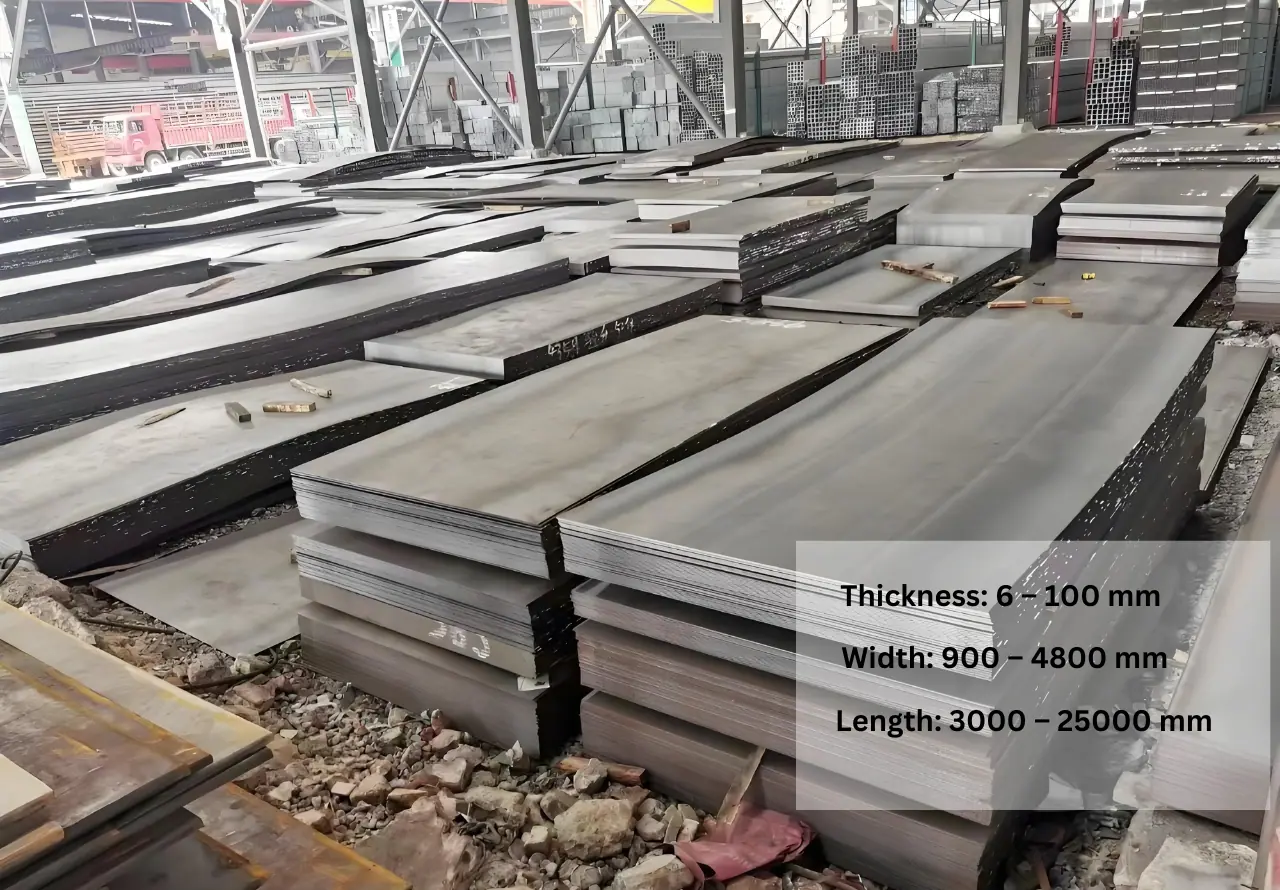

| Thickness | 6-100mm |

| Width | 900-4800mm |

| Length | 3000-25000mm |

| Weight | Depends on length and width |

| Outer diameter (OD) | Pipes:60 mm to 100 mm, Bars: 10 mm to 150 mm |

| Inner diameter (ID) | Pipes: 5 mm to 15 mm |

| Tolerances | Thickness: ±0.25 mm to ±1.0 mm, Width: ±2 mm to ±4 mm, Length: ±5 mm to ±10 mm |

| Technology | Hot Rolling |

| Processing Service | Welding, Punching, Cutting, Bending, Decoiling |

| Shapes | Weathering Steel Plate, Weathering Steel Sheet, Pipes, Profiles |

| MOQ (Minimum Order Quantity) | 5 tons (according to the actual tonnage) |

| Lead Time | Typically 7-20 days (The larger the ordered tonnage, the longer the delivery time) |

| Price Terms & Payment | Based on customer requirements, T/T, L/C |

| Ports | Qingdao, Lianyungang, Dalian |

| Export Countries | Southeast Asia, Central Asia, Europe, Russia, South America, Middle East, etc. |

| Shipping Method | Offers Sea, Air and Customized Shipping |

Chemical Compositions

| Element | A242 Type 1 Content (%) | A242 Type 2 Content (%) |

|---|---|---|

| Carbon, C | ≤ 0.15 | ≤ 0.15 |

| Chromium, Cr | 0.40 – 0.65 | 0.40 – 0.70 |

| Copper, Cu | 0.20 – 0.40 | 0.30 – 0.50 |

| Manganese, Mn | 0.20 – 0.50 | 0.20 – 0.60 |

| Nickel, Ni | ≤ 0.20 | ≤ 0.20 |

| Phosphorus, P | 0.07 – 0.15 | 0.08 – 0.15 |

| Silicon, Si | 0.15 – 0.30 | 0.15 – 0.30 |

| Sulfur, S | ≤ 0.05 | ≤ 0.05 |

Mechanical Properties

| Property | Type 1 (≤ 16mm) | Type 1 (> 16mm) | Type 2 (≤ 16mm) | Type 2 (> 16mm) |

|---|---|---|---|---|

| Tensile Strength | 480 MPa (70 ksi) | 460 MPa (67 ksi) | 480 MPa (70 ksi) | 460 MPa (67 ksi) |

| Yield Strength | 345 MPa (50 ksi) | 315 MPa (46 ksi) | 345 MPa (50 ksi) | 315 MPa (46 ksi) |

| Elongation (2 in / 50 mm) | 21% | 18% | 21% | 18% |

| Brinell Hardness | 170-190 HB | 170-190 HB | 170-190 HB | 170-190 HB |

| Rockwell Hardness | 84-92 HRB | 84-92 HRB | 84-92 HRB | 84-92 HRB |

| Vickers Hardness | 175-200 HV | 175-200 HV | 175-200 HV | 175-200 HV |

| Elastic Modulus | 190-210 GPa | 190-210 GPa | 190-210 GPa | 190-210 GPa |

Data After Normalizing Processing

| Property | Type 1 (≤ 16mm) (Normalized) | Type 1 (> 16mm) (Normalized) | Type 2 (≤ 16mm) (Normalized) | Type 2 (> 16mm) (Normalized) |

|---|---|---|---|---|

| Tensile Strength | 500 MPa (72 ksi) | 480 MPa (70 ksi) | 500 MPa (72 ksi) | 480 MPa (70 ksi) |

| Yield Strength | 365 MPa (53 ksi) | 335 MPa (49 ksi) | 365 MPa (53 ksi) | 335 MPa (49 ksi) |

| Elongation (2 in / 50 mm) | 20% | 18% | 20% | 18% |

| Brinell Hardness | 185-200 HB | 185-200 HB | 185-200 HB | 185-200 HB |

| Rockwell Hardness | 88-95 HRB | 88-95 HRB | 88-95 HRB | 88-95 HRB |

| Vickers Hardness | 190-210 HV | 190-210 HV | 190-210 HV | 190-210 HV |

| Elastic Modulus | 200 GPa | 200 GPa | 200 GPa | 200 GPa |

Industries & Applications

| Industries | Products |

|---|---|

| Bridges and Infrastructure | Bridge decking, support beams, guardrails, trusses, pedestrian walkways |

| Building Facades | Exterior wall panels, cladding, window frames, roofing, decorative facades |

| Railway and Transport | Railway cars, container sides, transport frames, coupler housings, platform decking |

| Energy and Power | Power line poles, wind turbine structures, transformer housings, cooling towers, equipment housings |

| Marine and Coastal | Dock structures, marine pilings, coastal barriers, port cranes, bulkheads |

| Agriculture Equipment | Grain bins, storage tanks, equipment frames, fencing, machinery panels |

| Industrial Equipment | Conveyor frames, processing tanks, protective casings, ventilation systems, loading platforms |

| Sculptures and Art | Monuments, outdoor sculptures, art installations, large statues, architectural structures |

| Highway Safety | Guardrails, median barriers, traffic signs, signal poles, safety barriers |

Packing

SteelPRO Group ensures A242 weathering steel is expertly packed for safe transport and handling. Our method addresses key challenges in packing A242 steel:

- Protective Coating: A weather-resistant layer is applied to prevent corrosion during transit, especially for overseas shipping where humidity control is critical.

- Durable Strapping and Securing: We use heavy-duty steel or polyester straps to secure materials, reducing the risk of shifting or damage, even in long-haul transport.

- Moisture Control and Wrapping: Each shipment includes moisture-resistant wrapping to shield the steel from direct water exposure, essential for maintaining the integrity of the rust-protective layer.

- Custom Palletizing: Our packing teams create customized pallets and supports for various steel shapes, from plates to bars, ensuring stability and easy unloading at destination sites.

SteelPRO Group’s packing process ensures our A242 weathering steel arrives in optimal condition, ready for immediate use.

Machining

A242 Heat Treatment Product Options

We provide A242 weathering steel in a variety of heat-treated forms to suit different application needs:

- Normalized A242: Available in plates and bars, normalized at 900°C for enhanced strength and uniformity, ideal for structural use.

- Annealed A242: Offered in sheets and sections, annealed at 700–750°C to improve formability, suitable for custom applications.

- Tempered A242: Provided in coil and strip forms, tempered at 200–600°C for added resilience, used in impact-resistant parts.

- Hot-Rolled A242: Available as plates, bars, and tubes in its untreated form, suitable for general weathering applications.

- Surface Options: Mill-finished and pre-rusted surfaces meet aesthetic needs, widely used in architectural designs.

A242 Surface Finish

To optimize performance, we offer a range of surface finishes tailored to A242 weathering steel applications:

- Shot Blasting: Provides a clean, roughened surface for enhanced adhesion of coatings or paint.

- Pickling: Removes scale and impurities, resulting in a smooth, uniform surface ideal for further processing.

- Oil Coating: Adds a thin layer of protective oil, reducing oxidation during storage and transit.

- Anti-Fingerprint Coating: Adds a transparent protective layer to reduce smudging and surface marks, commonly used in visible applications.

- Passivation: Enhances corrosion resistance by forming a protective oxide layer, ideal for extended outdoor use.

- Phosphating: Creates a corrosion-resistant base layer that improves paint adhesion, commonly used in construction and automotive parts.

Custom surface treatment requirements can be accommodated upon request.

A242 Weathering Steel Supplier

As a trusted supplier of A242 Weathering Steel, we offer comprehensive support across price, product range, quality, and logistics to meet your project needs:

- Competitive Pricing and Client Focus: We provide fair pricing while ensuring responsive support throughout your project, helping you achieve cost efficiency without compromising quality.

- Complete Product Range with Precision Options: Our A242 Weathering Steel selection covers plates, bars, coils, and sheets, with customization options for cutting, bending, and forming to meet exact specifications.

- Strict Quality Assurance and Certifications: Every batch undergoes rigorous testing, and we ensure certification according to standards like ASTM and EN, guaranteeing durability and compliance with industry requirements.

- Custom Solutions, Secure Packaging, and Reliable Logistics: We deliver tailored A242 solutions with safe packaging to prevent transit damage and provide efficient logistics, keeping you informed at every delivery stage.

With our expertise and commitment to quality, we are equipped to support both small-scale and large-scale A242 Weathering Steel projects.

Our Service

SteelPRO Group – manufacturer and solution provider for special steel, offering multi-industry application solutions and customised services, 100% quality free, accompanying customers in their growth!

Our Quality Control

- Roundness

- Tolerance

- Microstructure

- Non-Destructive Testing

- Destructive Testing

- Process Control

Service Integration Processing

- Welding

- Metal Fabrication

- CNC Machining

- Lathe

- Forming

What Is The Maximum Thickness Available For A242 Weathering Steel?

The maximum thickness for A242 can vary by supplier and equipment, but we typically offer up to 100 mm. Specific requirements can be custom-produced.

How Is A242 Priced Compared To Other Weathering Steels?

A242 is competitively priced relative to other high-performance weathering steels due to its composition and production scale, providing cost-effectiveness for large projects.

Does A242 Require Special Handling For Storage?

Yes, to maintain its weathering properties, A242 should be stored in a dry environment. We recommend using protective wrapping if extended storage is necessary.

Can Orders Be Adjusted Mid-Production If Specifications Change?

Yes, we offer flexible solutions. If adjustments are minor, we can usually incorporate them mid-production; significant changes may require additional lead time.

What Is The Expected Durability In Coastal Or High-Humidity Environments?

A242 performs well in corrosive environments but benefits from a pre-rusted or sealed finish in high-humidity areas to maximize longevity.

Are Documentation And Production Records Available Upon Request?

Yes, we provide complete documentation, including production records and quality inspection reports, to support traceability and compliance.

CONTACT

CONTACT

Certifications

Other Products

-

-

SteelPRO Group offers FH550 high-strength structural steel plates for shipbuilding....

-

SteelPRO Group offers DH550 high-strength shipbuilding steel plates in stock....

-

SteelPro Group offers FH36 high-strength steel for shipbuilding. It has...