ULTRA HIGH STRENGTH STEEL

Exceptional Strength, Durability for Automotive Construction and Aerospace.

Introduction to Ultra High Strength Steel(UHSS)

Ultra High Strength Steel (UHSS) has become increasingly popular in various industries due to its exceptional mechanical properties. UHSS typically offers yield strength and tensile strengths of 780 MPa (113 ksi) or higher, with ultimate tensile strength ranging from 980 MPa (142 ksi) to over 1500 MPa (218 ksi). These ultra high-strength levels make UHSS ideal for applications requiring maximum performance and durability.

UHSS is widely used in automotive frames and safety components, construction structures, bridges, and aerospace components. Additionally, it is applied in manufacturing heavy machinery, energy pipelines, railway tracks, shipbuilding, and defense equipment due to its superior mechanical properties and ductility. Its superior hardening and unique mechanical properties make it highly desirable across these industries.

Benefits of Ultra High Strength Steel

- Ultra-high strength steel particularly is valuable in industries high strength-to-weight ratio and performance are critical. The benefits of high strength materials include:

- Lightweight: Reduces overall weight in structures and vehicles, enhancing fuel efficiency.

- Increased Strength:Tensile strength of at least 780 MPa.

- Durability:UHSS steels with superior wear and corrosion resistance.

- Safety:Enhances impact protection and crash performance.

- Cost-Effective: Long lifespan reduces maintenance and production costs with lighter components.

- Formability: Can be shaped into complex forms easily.

- Weldability: Supports effective welding for intricate structures.

- Toughness: Combination of strength and toughness, good impact and fracture resistance.

To learn more about steel, check out our High Strength Steel page.

Types of Ultra High Strength Steel

- Ultra High Strength Steel includes several types, each offering specific properties and advantages:

- Dual Phase (DP) Steel: Known for its high strength and good ductility, making it ideal for automotive applications.

- Complex Phase (CP) Steel: Offers a balance of high strength and formability, suitable for structural components.

- Martensitic Steel: Provides extremely high strength and hardness, used in demanding applications like cutting tools and wear-resistant parts.

- Transformation Induced Plasticity (TRIP) Steel: Combines high strength with excellent ductility, used extensively in the automotive industry.

- Press Hardened Steel (PHS): Known for its high strength after heat treatment, used in automotive safety components.

Industries & Applications

Some common industries and applications include:

Automotive Industry

Construction Industry

Aerospace Industry

Utilized in aircraft components to reduce weight and maintain structural integrity.

Manufacturing

Energy Sector

Railway Industry

Shipbuilding

Defense Industry

Dimensions & Properties

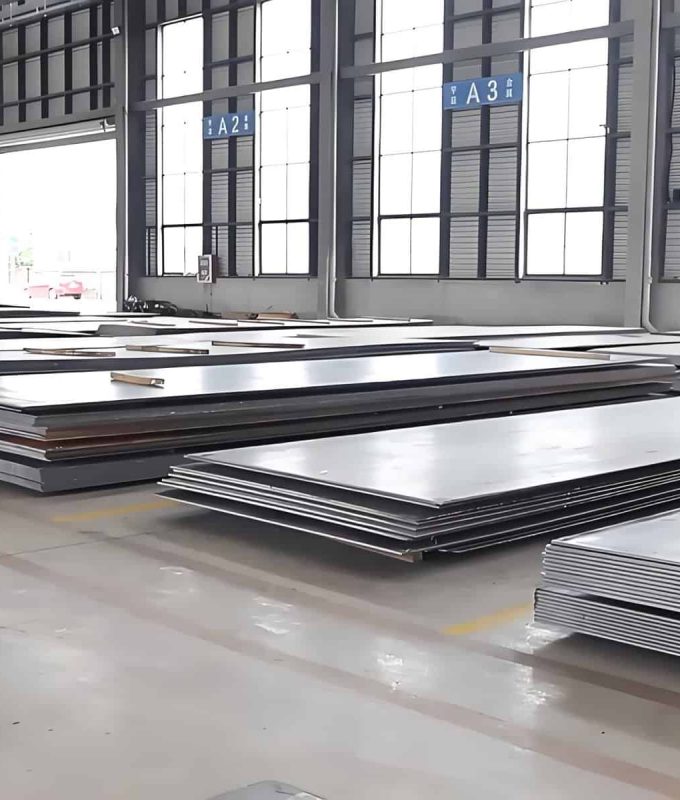

Whether steel qualifies as plate or sheet depends on the specification used for certification. There is a large overlap in popular thicknesses between plate and sheet, but steel plates are offered in a much broader range of sizes.

| Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Tensile Strength | 515 - 750 MPa | 74,700 - 108,800 psi |

| Yield Strength | ≥ 205 MPa | ≥ 29,700 psi |

| Elongation | ≥ 40% | ≥ 40% |

| Hardness (Brinell) | ≤ 217 HB | ≤ 217 HB |

| Hardness (Rockwell B) | ≤ 95 HRB | ≤ 95 HRB |

| Hardness (Vickers) | ≤ 225 HV | ≤ 225 HV |

| Elastic Modulus | 200 GPa | 29,000 ksi |

Ultra High Strength Steels When & Where You Need It

Explore Our Available Steel Products & Grades

Our knowledge and experience give nearly 100% accurate delivery of High Carbon, Low Carbon, Stainless Steel products processed and packaged to your exact specifications.

Is ultra high strength steel repairable?

Yes, ultra high strength steel can be repaired, but it requires specialized techniques and equipment due to its high strength properties.

What is the difference between mild steel and ultra high strength steel?

Mild steel has lower yield and tensile strength, making it more ductile and easier to weld. Ultra high strength steel has significantly higher yield and tensile strength, providing greater load-bearing capacity and durability.

Are there any specific storage requirements for Ultra High Strength Steel?

Ultra high strength steel should be stored in a dry, covered area to prevent corrosion and damage. Proper stacking and handling practices should be followed to maintain its integrity.

How does the cost of Ultra High Strength Steel compare to standard steel?

Ultra high strength steel is generally more expensive than standard steel due to its enhanced properties and production processes. However, its superior performance can lead to long-term cost savings.

Are custom sizes and specifications available for Ultra High Strength Steel products?

Yes, custom sizes and specifications are available for ultra high strength steel products to meet specific project requirements.