Heat Straightening

SteelPRO Group offers expert heat straightening services to restore deformed metal parts to their original shape with precision and care, ensuring structural integrity and durability.

What is Heat Straightening?

Heat straightening is a metalworking process that restores deformed metal to its original shape by controlled heating of specific areas. This technique takes advantage of metal’s expansion when heated and contraction when cooled to correct distortions.

It is commonly used in construction, transportation, and manufacturing to repair damaged components such as beams, bridges, and heavy machinery, as well as to correct manufacturing defects. Heat straightening is applicable to various metals, including steel and aluminum, and can be performed in workshops or on-site.

In some cases, additional processing such as stress relief or annealing may be required to fully restore the strength and integrity of the part.

Which Metal Types Can Be Heat Straightened?

Heat straightening works on metals that can withstand controlled heating without losing mechanical properties, allowing for effective expansion and contraction:

- Plates: Restores flatness and corrects warping caused by heat or mechanical damage.

- Sheets: Straightens thin, deformed sections while maintaining dimensional accuracy.

- Angles: Realigns bent or twisted angles to their original form for structural integrity.

- Channels: Corrects distortions in channel flanges and webs to restore proper alignment.

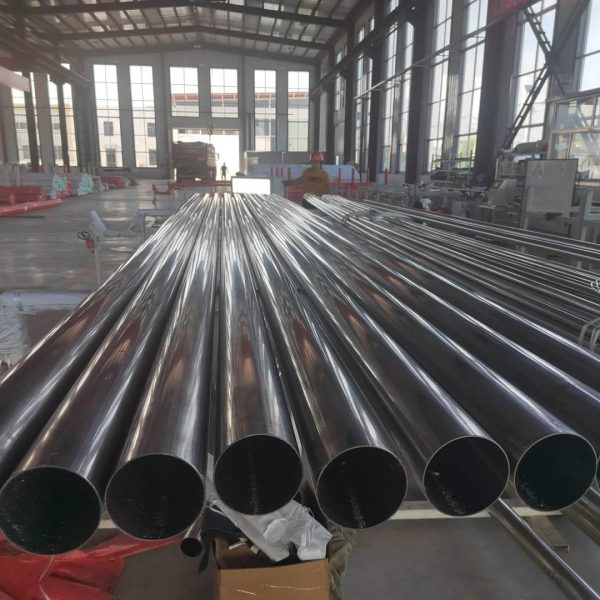

- Pipes: Straightens bent or damaged pipes, ensuring proper flow and structural strength.

- Tubes: Restores roundness and eliminates bends in tubes for precise application.

- Beams: Repairs deformed beams, ensuring they can carry loads as designed.

- Bars: Straightens bent bars, maintaining their strength and load-bearing capacity.

Why Choose Us for Heat Straightening

- Expertise Across Metal Types

We have extensive experience in heat straightening a wide range of metals, including carbon steel, stainless steel, and alloy steel. - Precision and Care

Our controlled heating process ensures accurate corrections without compromising the metal’s structural integrity. - Workshop Services

Our workshop is fully equipped to handle heat straightening for projects of any size, ensuring reliable and efficient results. - Comprehensive Support

We provide additional treatments like stress relief and annealing to fully restore strength and durability to your components.

FAQ

How do you prevent overheating the metal during heat straightening?

We use controlled heating techniques, carefully monitoring temperatures to avoid exceeding critical limits that could weaken the metal.

What if the metal doesn’t return to its original shape after heating?

Multiple heating and cooling cycles can be applied, along with precise force, to gradually guide the metal back to its original form.

How do you handle residual stress after heat straightening?

We offer post-process stress relief treatments, such as annealing, to minimize residual stresses and restore the metal’s strength.

Can heat straightening be used on severely deformed parts?

Yes, but the extent of deformation matters. For severe cases, we use advanced methods, combining heat straightening with mechanical adjustments to achieve the desired results.

What is the process of heat straightening?

Heat straightening involves controlled heating of deformed metal areas, typically to 600-700°C, followed by natural cooling. As the metal cools, it contracts, helping to return it to its original shape. Mechanical force may be applied during the process to guide the deformation more effectively.

How long does the heat straightening process take?

The time depends on the size and complexity of the part, but we aim for fast turnaround while ensuring quality results.

What types of metals can be heat straightened?

We can heat straighten a wide range of metals, including carbon steel, stainless steel, and alloy steel, ensuring precision for each material.

Will heat straightening affect the strength of the metal?

No, when done correctly, heat straightening preserves the metal’s structural integrity, and we offer additional treatments if needed to fully restore strength.