DX52D Galvanized Steel Coil

DX52D Galvanized Steel Coil

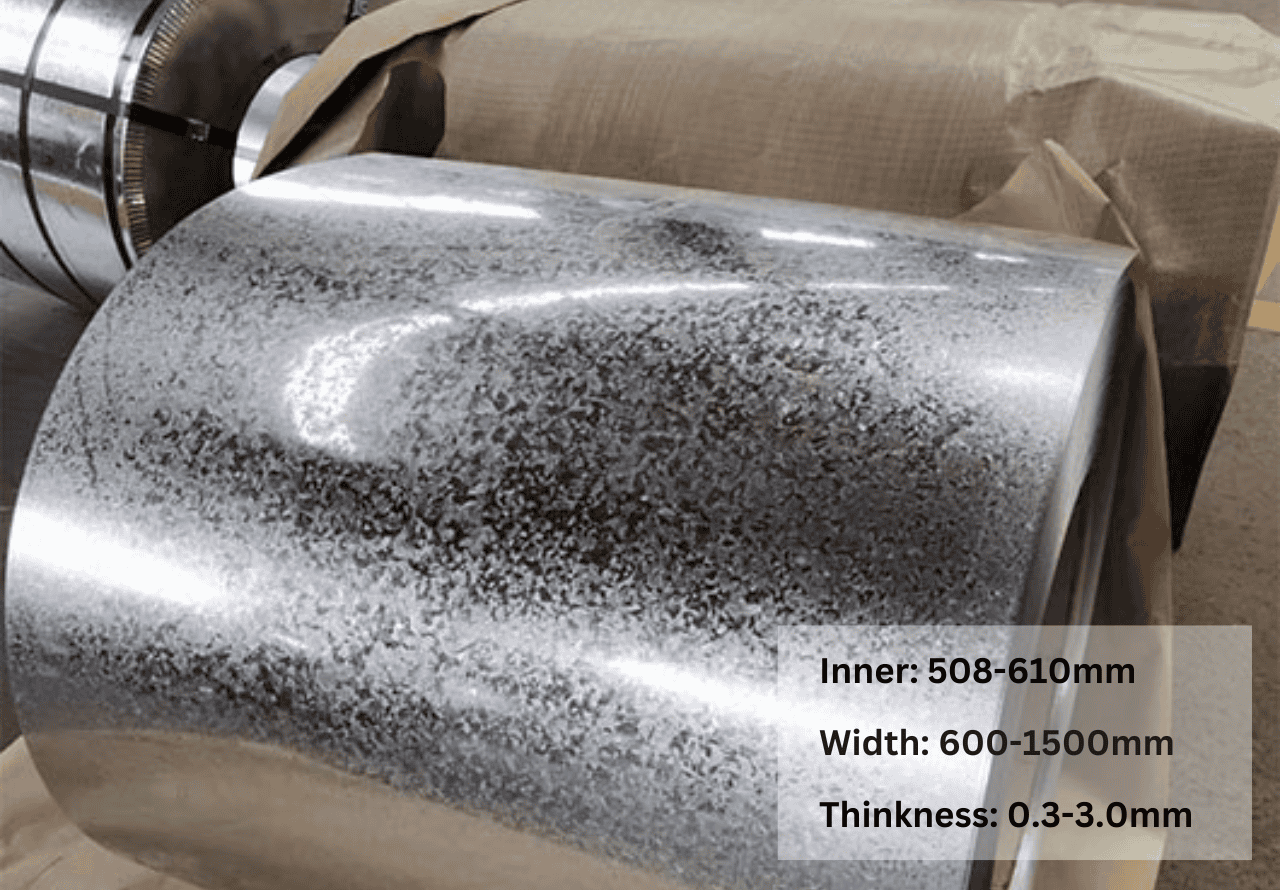

DX52D Coil is a very practical galvanized steel coil with good formability. We provide DX52D Gi coils, plates, tubes and other grades of galvanized steel products in accordance with standards such as EN 10346. Our steel coils have excellent corrosion resistance and are suitable for use in industries such as construction, automobiles, and home appliances. The thickness ranges from 0.3mm to 3.0mm, the width can be customized, and the zinc coating weight can be adjusted according to needs, providing excellent strength and durability to ensure long-term use.

- Special Use: Color coated sheet

- Standard: EN 10346, GB/T 2518-2008, JIS G 3302, ASTM A653/A653M, ISO 3575

- Grades: DX52D, DX52D+Z, CS Type A/B, SGCD2, SECC

- Technology: Cold Rolling, Hot-dip Galvanizing, Electro-galvanizing

- Certification: ISO 9001, CE

DX52D Galvanized Steel Coil

DX52D Galvanized Steel Coil

Product Specifications

Product Specifications

| Product Name | DX52D Galvanized Steel Coil |

| Thickness | 0.3mm~3mm, Customized |

| Width | 600mm – 1500mm, Customized |

| Length | Customized |

| Coil Inner | 508mm – 610mm, Customized |

| Zinc Layer | 30g – 275g/m² |

| Spangle | big, regular, mini, and zero spangles |

| Surface Treatment | anti-finger print /skin pass/oiled/ dry/chromated/Embossed/Lamination |

| Surface quality | A, B |

| Surface | Matt,High gloss,Color with two sides,Wrinkle,Wooden color,Marble |

| Test | Zinc Coating Thickness Test, Bend, Cross-hatch, Salt Spray Test, Tensile Test, etc. |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Invoicing | by actual weight |

| Delivery Time | 7-15 days |

| Payment | T/T, L/C, Credit Card |

| Port | Shanghai, Qingdao or according to your requirement |

| Packaging Details | In bundles, in bulk, customized packing |

Chemical Compositions

Chemical Compositions

| Element | Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Nitrogen (N) | Aluminum (Al) |

|---|---|---|---|---|---|---|

| Percentage (%) | ≤ 0.12 | ≤ 0.60 | ≤ 0.10 | ≤ 0.045 | ≤ 0.009 | ≤ 0.015 |

Mechanical properties

Mechanical properties

| Property | Value |

|---|---|

| Yield Strength (Re) | ≤ 280 MPa |

| Tensile Strength (Rm) | 270 – 420 MPa |

| Elongation (A80) | ≥ 26% |

Industries & Applications

Industries & Applications

- Automotive Industry: Due to its excellent formability, it can be used to manufacture body panels, doors and other structural parts.

- Construction: Used for roofing, wall coverings and building structural parts, with corrosion resistance.

- Home Appliances: Used in the production of washing machine bodies, refrigerators and other home appliances. Due to its durability and corrosion resistance, it is suitable for air conditioning ducts, ventilation systems and heating equipment.

- Electrical Enclosures: Due to its high strength and protective coating, it can be used to manufacture electrical boxes and cabinets.

- Food Processing Industry: Galvanized coils are used to manufacture conveyor belts, shelves, containers, etc. in the food processing industry. Its smooth, corrosion-resistant surface meets food safety standards and ensures food quality and hygiene.

- Agricultural Sector: Galvanized coils are widely used in agricultural equipment, greenhouse brackets, etc. Its strong corrosion resistance and long service life make it an important material for agricultural production.

- General Manufacturing: Due to its versatility, it is very suitable for various stamping, forming or welding parts in different industries.

Other Infomation

Other Infomation

Why choose our DX52D galvanized steel coil?

Compared with other galvanized steel coils on the market, choosing our DX52D Gi Coil has the following advantages.

- Some products on the market have uneven coating, resulting in poor corrosion protection, especially in harsh environments.

- Other brands may not be stable enough during processing, prone to cracks or surface defects, while DX52D Gi Coil has stable processing performance and high ductility.

- Low-priced brands may not meet environmental standards and have a shorter service life, increasing subsequent maintenance costs. Our products not only have a long service life and beautiful surface, but are more cost-effective in long-term use and are a more reliable choice.

Our Inventory

Our Inventory

With an annual production capacity of more than 1 million tons, SteelPRO Group is an excellent steel supplier, operating three independent plants and working with renowned manufacturers. Our comprehensive range of services includes production, processing and efficient logistics. We excel in stability of supply, wide range of products, high quality standards, competitive prices, fast delivery times and excellent after-sales support.

Main products: steel coils, plates, bars, carbon steels, stainless steels, galvanized steels, structural steels and special steels for the construction, automotive, manufacturing and energy industries.

Packing

Packing

SteelPRO Group exports to countries and regions such as the Middle East, South America, Europe and South East Asia with strong international sales. Our tailor-made packaging solutions for all steel types ensure security, sealing and corrosion protection. Within our transportation procedures, we include regular inspection and maintenance of transportation equipment to prevent exposure to moisture or standing water. Furthermore, we label all shipments with detailed information in accordance with international standards to ensure the safety and quality of the steel throughout the transportation process.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

What service does you Provide?

In addition to selling raw materials, we also perform machining services such as cutting, milling, grinding, turning, peeling, drilling, CNC machining and customized options.

What ports of shipment are there?

Generally, we ship from ports such as Shanghai and Qingdao, and you can specify other ports according to your needs.

What about product prices information?

Prices vary according to regular price changes of raw materials. But you can get extremely affordable wholesale prices from us.

Are You Manufacture or Trade Company?

We are a professional steel manufacturer, producing a series of products such as stainless steel, galvanized steel, wear-resistant steel, high-strength steel, etc. Welcome to contact us and visit our factory before placing an order.

Can I visit your factory?

Of course, you are welcome to visit our factory. Please contact us in advance so that we can arrange a suitable visit time for you. We will do our best to guide you and ensure that your visit experience is both fulfilling and enjoyable.

What product information do I need to provide?

You need to provide the brand, width, thickness, coating and tonnage you need to purchase.

CONTACT

Certificates and Cooperation

Certificates and Cooperation