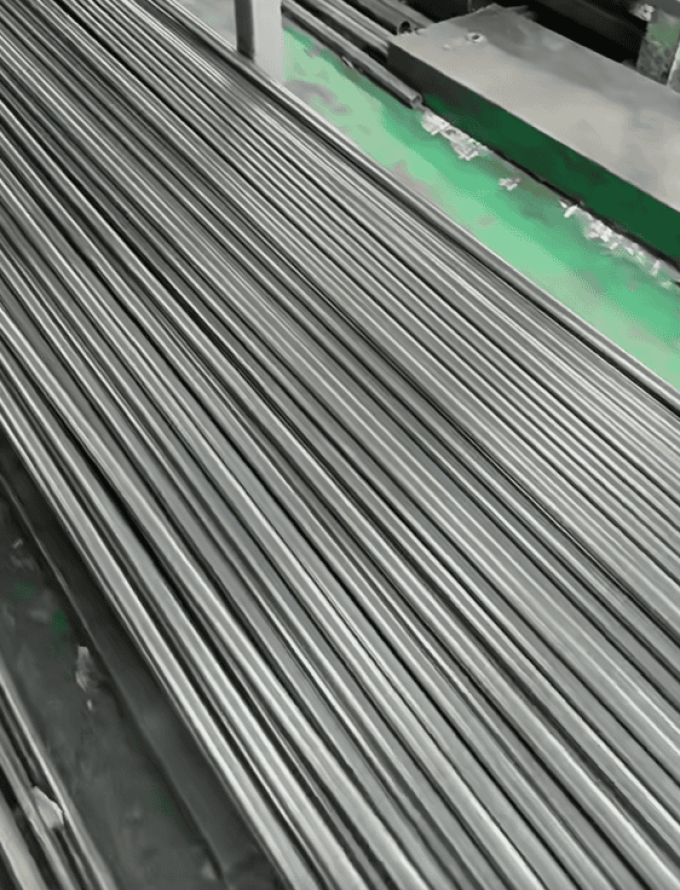

COLD ROLLED STEEL BAR

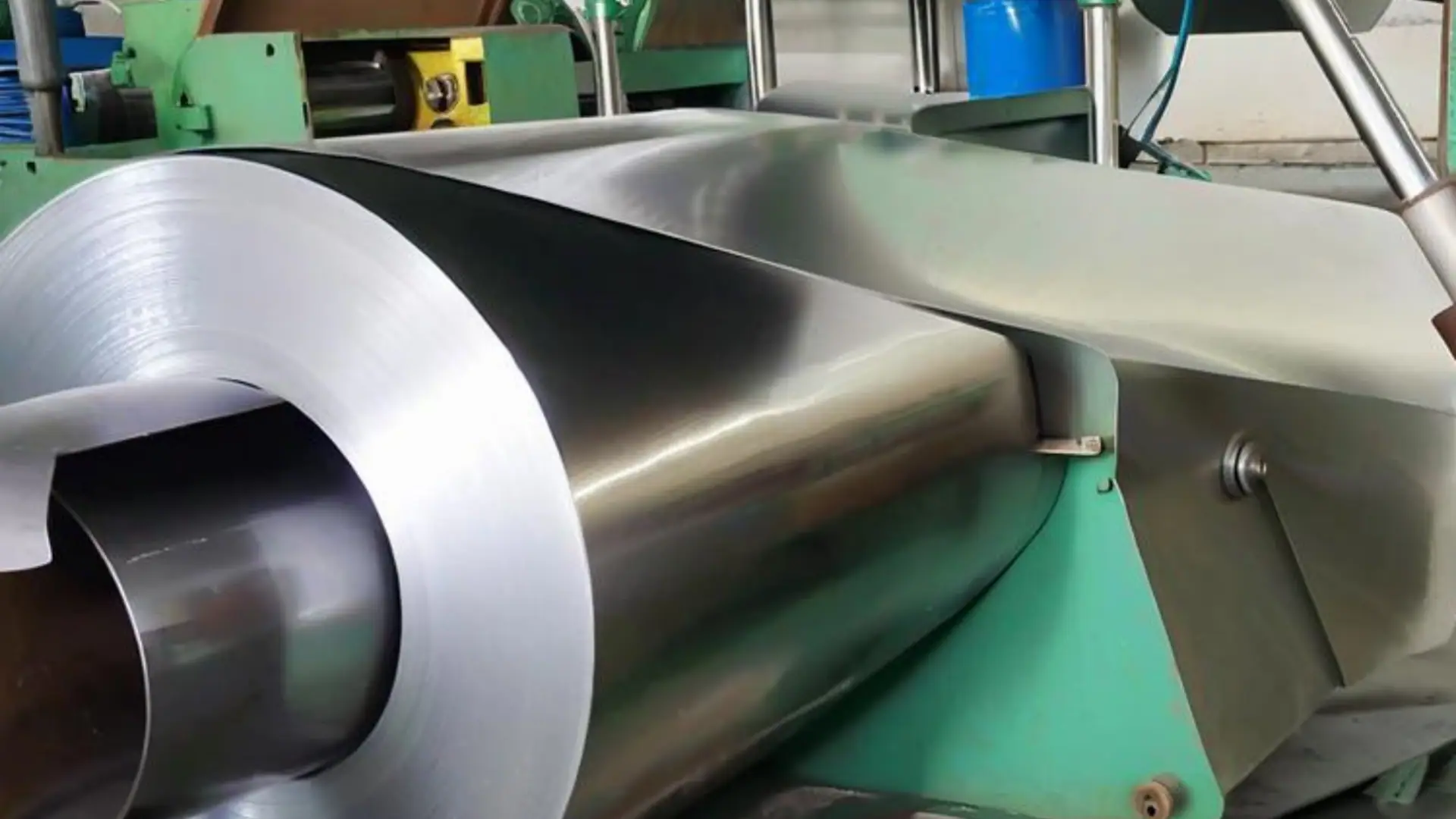

We aim to deliver high-quality cold rolled steel bars through advanced manufacturing processes. Our bars, produced at room temperature, boast superior strength, surface finish, and accuracy.

These steel bars are perfect for automotive, construction, machinery, and industrial tools, offering unmatched performance and reliability. Compared to hot rolled bars, our cold rolled steel bars provide higher tensile and yield strength. We understand the importance of cost-effectiveness and are committed to providing competitive pricing without compromising on quality.

Choose us as your go-to supplier for cold rolled steel bars, and experience the benefits of superior quality, attractive pricing, and rapid delivery.

What are Cold Rolled Steel Bar

Cold Rolled Steel Bar Type

Cold rolled steel bars come in round, flat, hexagon, and square shapes, designed for specific industry needs. Whether you need a round bar, flat bar, or another shape, we have it covered.

| Type | Size Ranges | Applications | |

|---|---|---|---|

| Diameter from 0.2 inches to 4 inches | Shafts, Axles, Bolts | get a quote |

| Across flats from 0.24 inches to 3 inches | Fasteners, Nuts, Bolts | get a quote |

| Side length from 0.2 inches to 4 inches | Tool handles, Ornamental ironwork | get a quote |

| Thickness 0.08 inches to 2 inches | Brackets, Base plates, Braces | get a quote |

Cold Rolled Steel Bar Grades

| Standard | USA | SIZE | |

|---|---|---|---|

| ASTM A29 | AISI 1015 | 1/4'' - 2'' | get a quote |

| ASTM A108 | AISI 1018 | 1/4'' - 4'' | get a quote |

| ASTM A108 | AISI 1045 | 1/4'' - 4'' | get a quote |

| ASTM A108 | AISI 4140 | 1/4'' - 4'' | get a quote |

| ASTM A108 | AISI 12L14 | 1/8'' - 3'' | get a quote |

| ASTM A108 | AISI 1020 | 1/4'' - 2'' | get a quote |

Quality Assurance for Cold Rolled Steel Bars

Regular Quality Inspections

- Mechanical Properties: Testing tensile and yield strength, hardness.

- Dimensional Accuracy: Measuring diameter, thickness, and length.

- Surface Finish: Checking for smoothness and defects.

- Chemical Composition: Verifying alloy mix.

Extreme Testing

- Corrosion Resistance: Testing in corrosive environments.

- Impact Testing: Assessing toughness under sudden impacts.

- Fatigue Testing: Evaluating endurance under repeated stress.

- Temperature Resistance: Assessing performance at extreme temperatures.

If you have specific requirements, we can customize additional tests to meet your needs.

To ensure the safe and secure transportation of our steel bars, we use robust packaging methods:

-

Secured Bundling: Bars are securely bundled with steel straps and wooden supports. Finished products are shipped in wooden crates.

-

Protective Coatings: Our steel bars are coated to prevent corrosion and damage during transit. Additional coating options are available upon request.

-

Labeling and Documentation: Each shipment is clearly labeled and comes with detailed documentation for easy tracking.

Several factors impact the performance of cold rolled steel bars, essential for selecting the right type for specific applications.

- Material Quality: Purity and alloy composition.

- Manufacturing Process: Precision in rolling and cooling techniques.

- Heat Treatment: Proper annealing and tempering.

- Surface Finish: Smoothness and absence of defects.

- Dimensional Accuracy: Consistency in size and shape.

- Environmental Exposure: Resistance to corrosion and extreme temperatures.

Because cold rolling is limited for large sizes, cold rolled bars are usually smaller than hot rolled bars. For large applications, consider hot rolled steel bars.

Proper storage of cold rolled steel bars is crucial for maintaining their quality. Environmental factors and transportation significantly impact their performance.

- Environment: Store in a dry, ventilated area to prevent rust.

- Temperature: Maintain stable temperatures to avoid stress and deformation.

- Humidity Control: Use dehumidifiers or desiccants.

- Transportation: Use protective packaging to prevent damage.

- Handling: Use proper lifting equipment to avoid bending.

- Storage Method: Store bars horizontally to prevent bending and separately to avoid contamination.

Usage & Application of Cold Rolled Steel Bar

Discover the diverse applications of cold rolled steel bars across various industries, highlighting their versatility and reliability.

- Automotive Manufacturers: Drive shafts, axles, gear systems

- Construction Companies: Structural frameworks, reinforcement bars, support beams

- Machinery Manufacturers: Gears, bearings, shafts

- Tool Manufacturers: Drill bits, cutting tools, machine parts

- Aerospace Companies: Landing gear, engine parts, structural elements

- Furniture Makers: Table legs, chair frames, decorative elements

Why Choose Our Cold Rolled Steel Bars

Choose our high strength steel bars for their exceptional quality and strength, backed by comprehensive documentation to ensure reliability and performance. We offer a wide selection and customization options to meet your specific needs, all at competitive pricing.

Additionally, our commitment to timely delivery and responsive service ensures you receive your order promptly and with the support you need.

Trust us for high strength steel bars that combine quality, customization, and excellent customer service.