8 | 9 | 10 Gauge Galvanized Steel Wire

8 | 9 | 10 Gauge Galvanized Steel Wire

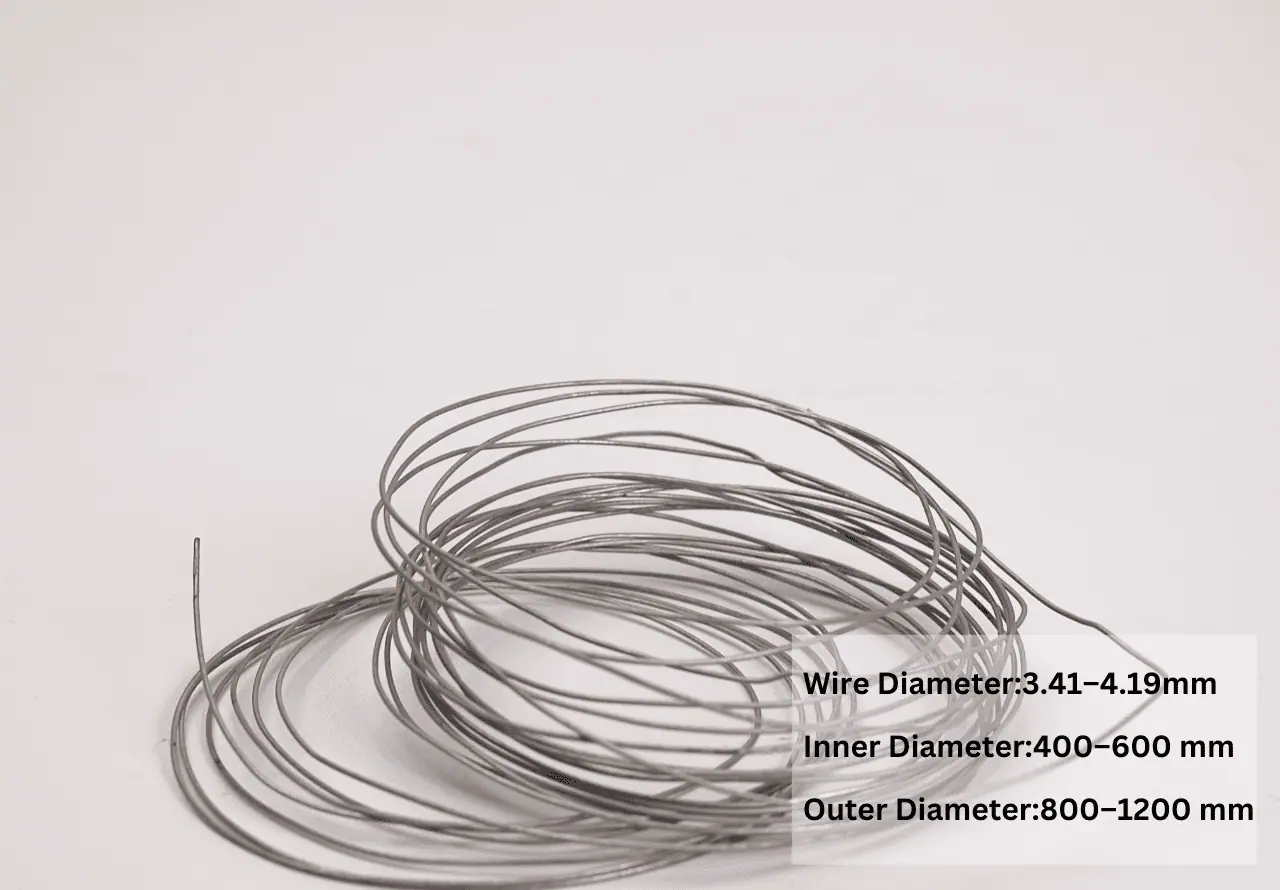

SteelPRO Group provides 8, 9, 10 gauge galvanized steel wire in various forms such as coils and straight bars, with electro-galvanizing and hot-dip galvanizing to meet different strength and corrosion protection requirements. We ensure that each batch of products meets international quality standards and has excellent tensile strength and ductility for long-term applications in harsh environments. SteelPRO Group also provides custom specifications and tailor-made services to meet the specific requirements of various professional projects.

- Standards: ASTM A641/A641M, EN 10244, etc.

- Grades: Q195, Q235, G550etc.

- Wire gauge: 8 gauge, 9 gauge, 10 gauge

- Technology: Hot-dip Galvanizing, Electroplating

- Form: Coil, Spool, Rope, Mesh, Straight bar

- Special Use: Gabion, fencing, kites, springs, grounding systems, cables, etc.

- Certification: ISO 9001, CE

8 | 9 | 10 Gauge Galvanized Steel Wire

8 | 9 | 10 Gauge Galvanized Steel Wire

Product Specifications

Product Specifications

|

Product Name |

8 Gauge Galvanized Wire |

9 Gauge Galvanized Wire |

10 Gauge Galvanized Wire |

|

Wire Diameter |

4.19 mm |

3.76 mm |

3.41 mm |

|

Wire Coil Weight |

20-1200kg |

||

|

Wire Coil Length |

Varies by coil weight |

||

|

Coil Outer Diameter |

800 – 1200 mm |

||

|

Coil Inner Diameter |

400 – 600 mm |

||

|

Zinc Layer |

20-400g/m², g30, g40, g60, g90, etc. |

||

|

Elongation |

10-15% |

||

|

Tensile strength |

400-550 MPa |

400-550 MPa |

400-550 MPa |

|

Load strength |

1000-1500 N |

800-1200 N |

600-1000 N |

|

Coating Material |

Polyester (PE), Silicone Polyester (SMP), High Durable Polyester (HDP), Fluoropolymer (PVDF) |

||

|

Surface Treatment |

anti-finger print/skin pass/oiled/dry/chromated/Embossed/Lamination |

||

|

Test |

Zinc Coating Thickness Test, Adhesion Test, Peel, Bend, Salt Spray Test, Tensile Test, Elongation, etc. |

||

|

Tolerance |

±1% |

||

|

Processing Service |

Bending, Welding, Decoiling, Cutting, Punching |

||

|

Invoicing |

By actual weight |

||

|

Delivery Time |

7-15 days |

||

|

Payment |

T/T, L/C, Credit Card |

||

|

Port |

Shanghai, Qingdao or according to your requirement |

||

|

Packaging Details |

In bundles, in bulk, customized packing |

||

Chemical Compositions

Chemical Compositions

| Element | Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon (Si) |

|---|---|---|---|---|---|

| Content (Max, %) | 0.06-0.12% | 0.30-0.60% | ≤ 0.03% | ≤ 0.03% | 0.10-0.30% |

Mechanical properties

Mechanical properties

| Gauge (AWG) | 8 | 9 | 10 |

|---|---|---|---|

| Tensile Strength (MPa) | 450-550 | 430-530 | 410-510 |

| Yield Strength (MPa) | 350-450 | 330-430 | 310-410 |

| Elongation (%) | 10-14 | 11-15 | 12-16 |

| Vickers Hardness (HV) | 130-150 | 125-145 | 120-140 |

| Brinell Hardness (HB) | 110-130 | 105-125 | 100-120 |

| Rockwell Hardness (HRB) | 60-75 | 58-73 | 55-70 |

| Elastic Modulus (GPa) | 200 | 200 | 200 |

Industries & Applications

Industries & Applications

Large diameter 8, 9, and 10 gauges are suitable for high-strength, heavy-duty structural scenarios.

- Building reinforcement: used for high-load-bearing requirements such as concrete structure support and frame reinforcement.

- Heavy-duty fencing: suitable for farm fencing, pasture fencing, and high-strength fencing in industrial sites.

- Industrial support: used for bundling and fixing large machinery and equipment, and can be used for a long time in harsh environments.

- Port and coastal engineering: Due to the strong corrosion resistance of large-diameter steel wire, it is suitable for high-salt environments such as coastal protection and port fencing.

Other Infomation

Other Infomation

When choosing a galvanizing process, there are two common methods: hot-dip galvanizing and electro-galvanizing. Both processes have their own advantages, depending on your specific usage requirements.

- Hot-dip galvanizing is to cover the surface of the steel wire with a thicker layer of zinc, which is very strong. The steel wire produced by this process is extremely corrosion-resistant and is especially suitable for outdoor environments, and is durable even in places with heavy humidity or salt. If your project is outdoors, such as fences, agricultural facilities, and building reinforcement, hot-dip galvanizing would be a better choice.

- The electro-galvanized coating is relatively thin, with a smooth and uniform surface and a delicate appearance. Although its corrosion resistance is not as strong as hot-dip galvanizing, electro-galvanized steel wire can also prevent rust well in indoor environments or slightly humid places. Electro-galvanized steel wire is suitable for projects that require appearance and do not require extremely high corrosion resistance, such as interior decoration, light frames, or some home projects.

In short, if your project is outdoors, durability is prioritized, choose hot-dip galvanizing; if it is indoors, pay attention to appearance, electro-galvanizing is more suitable.

Galvanized steel wire is actually very stable in different temperature environments, but there are still some temperature tips to help you make better use of it.

- In high temperature environments, galvanized steel wire can generally withstand temperatures up to about 200°C. The zinc layer performs well in this range and can maintain its corrosion resistance. However, if it exceeds 200°C, the coating may begin to oxidize and lose its protective effect. Therefore, in high temperature applications, it is best to keep the temperature below 200°C. Short-term high temperatures can be tolerated, but long-term high temperatures are not recommended for galvanized steel wire.

- In terms of low temperatures, galvanized steel wire performs better and can usually withstand extremely low temperatures, such as -40°C or even lower. The zinc layer will not become brittle at low temperatures, and the toughness of the steel wire itself will not be affected. Therefore, if your project is outdoors in the cold, galvanized steel wire is still a very reliable choice. However, in extremely cold environments, try to avoid severe bending to maintain its strength.

- In extreme temperature environments, such as places where the temperature changes frequently, you can add an anti-corrosion coating to the steel wire, or check the surface regularly to ensure that the coating is intact. Proper tension distribution also helps to prevent the wire from being damaged due to thermal expansion and contraction.

Our Inventory

Our Inventory

SteelPRO Group has won the trust and long-term cooperation of many industry partners with its strong production capacity and high standards of quality control. Our production facilities are equipped with advanced automated production lines to ensure efficient production while maintaining excellent quality. The annual output reaches one million tons, which can meet the needs of projects of all sizes. Cooperation with many internationally renowned brands and large engineering companies enables us to respond quickly to market changes and meet the diverse needs of customers. In addition, strict quality inspection processes and experienced technical teams ensure that our products always maintain leading competitiveness in the market.

Main products: galvanized steel wire, steel pipes, steel plates, steel coils, steel bars, steel strips, stainless steel series, carbon steel series, high-strength steel series, nuclear grade steel, galvanized steel, steel for wind and solar energy, etc.

Packing

Packing

Our product packaging is carefully designed to ensure safety and convenience during transportation. Depending on the product type and customer needs, we provide a variety of packaging methods, including standard bundling, pallet packaging and waterproof protective packaging to adapt to different transportation conditions. Each batch of products will be strictly inspected before leaving the factory to ensure that the packaging is intact and provide customers with a high-quality delivery experience.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

Can galvanized steel wire be used in power projects?

Yes, many customers use these steel wires in power projects as strapping and support materials. Their high strength and durability make them ideal for outdoor power facilities.

Will the zinc coating wear out over time?

The zinc coating is very wear-resistant in daily use, but may gradually reduce in environments with strong friction or high wear. We use a high-quality galvanizing process to extend the service life of the steel wire, especially for durability in outdoor applications.

Are SteelPRO Group's products environmentally certified?

Yes, our production process meets environmental standards, and all galvanized steel wire products have passed relevant environmental certifications to ensure that they are harmless to the environment and suitable for various projects with strict environmental requirements.

Does SteelPRO Group provide preferential solutions for large-volume purchases?

Yes, we have flexible pricing plans for customers who purchase in large quantities. You can contact the sales team directly for more information and specific quotes.

Are galvanized steel wires No. 8, 9, and 10 suitable for underwater projects?

Yes, the zinc coating of these wires provides excellent corrosion protection and is suitable for short-term or temporary underwater fixing projects, but additional protective measures are recommended to extend the underwater service life.

How does SteelPRO Group conduct quality inspections?

Each batch of steel wires undergoes rigorous tensile strength, corrosion resistance and coating thickness tests before leaving the factory to ensure that they meet quality standards, and test reports are provided for customer inspection.

CONTACT

Certificates and Cooperation

Certificates and Cooperation