CGCC Galvanized Steel Corrugated Roofing Sheet

CGCC Galvanized Steel Corrugated Roofing Sheet

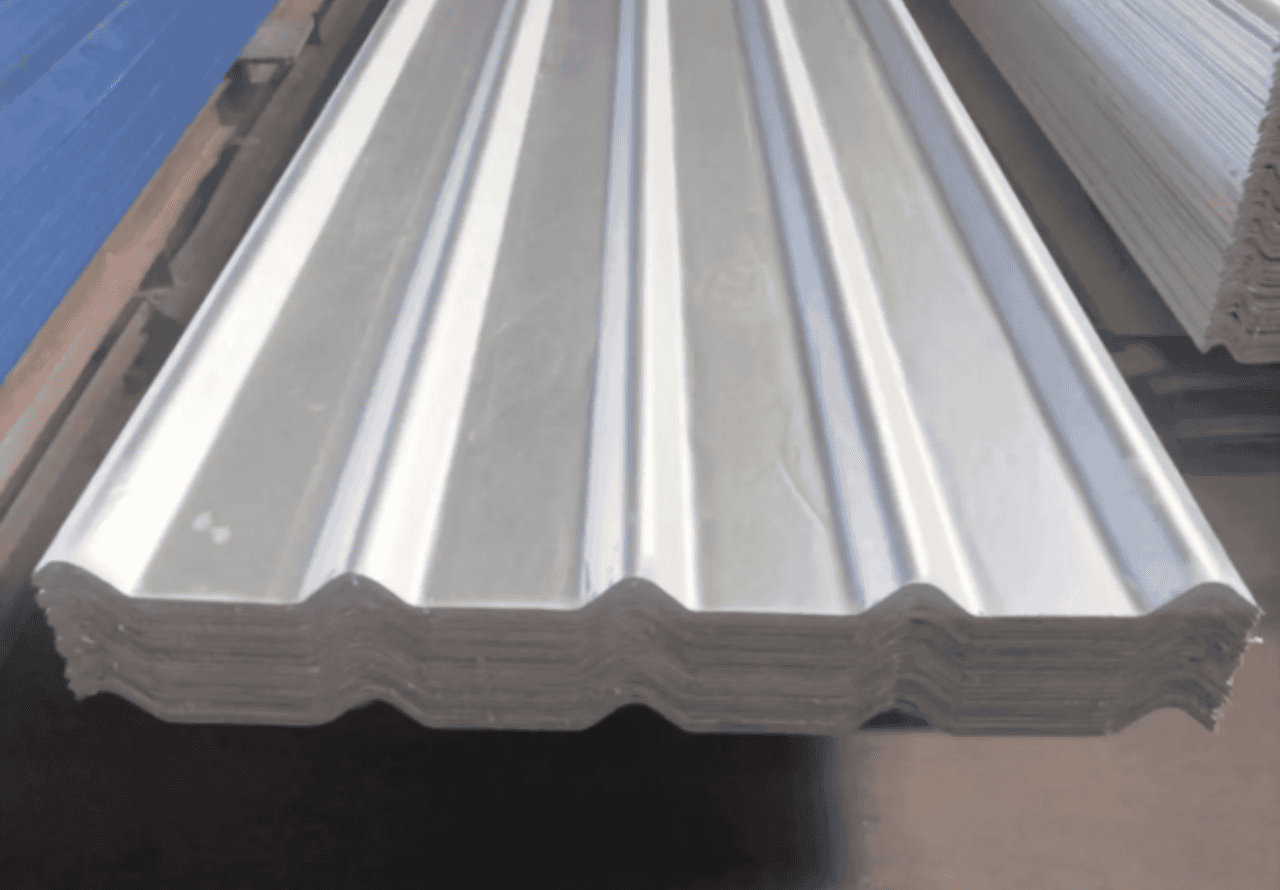

Galvanized steel supplier and manufacturer SteelPRO Group is committed to providing customers with high-quality, corrosion-resistant, high-strength galvanized steel products. We have a variety of CGCC galvanized steel roof panels, including ordinary galvanized, color-coated, galvanized and anti-fingerprint types. Our products are rich in form, including coils, flat sheets, corrugated sheets and trapezoidal sheets, as well as SGCC, SPCC and other brands, suitable for all kinds of construction needs.

- Standard: JIS G3312, ASTM A755/A755M, EN 10346

- Grades: CGCC, SGCC, SPCC, DX51D, Q195, CS-B, etc.

- Technique: Hot-Dip Coating, cold rolling

- Substrate: Hot dip galvanized steel sheet

- Roofing Sheet Type: Corrugated Sheets, PBR Panel, Standing seam galvanized metal roof, Bare Galvalume Roofing Sheet, PPGI Roofing Sheets, etc.

CGCC Galvanized Steel Corrugated Roofing Sheet

CGCC Galvanized Steel Corrugated Roofing Sheet

- Compared with some ordinary galvanized steel sheets on the market, our CGCC roof panels are not only corrosion-resistant, but also superior in beauty, durability and impact resistance. We use a strict coating control process to ensure that each layer of coating is even and firm, thus avoiding the uneven coating or easy peeling of some products on the market. Even under long-term sun and rain, they can still provide excellent protection, prevent rust and extend service life.

- Our roof panels are not only tough, but also have good flexibility, which is very suitable for large-scale installation or complex shapes. Even if they are bent during construction, they will not easily crack or warp, which improves the use effect and installation convenience.

- Our CGCC also provides a variety of colors and surface treatment options, which are not only beautiful, but also ensure durability and brightness under different light and climate conditions. Especially in terms of wind resistance and strength, our products have passed rigorous testing and are very suitable for areas with strong winds or extreme climates.

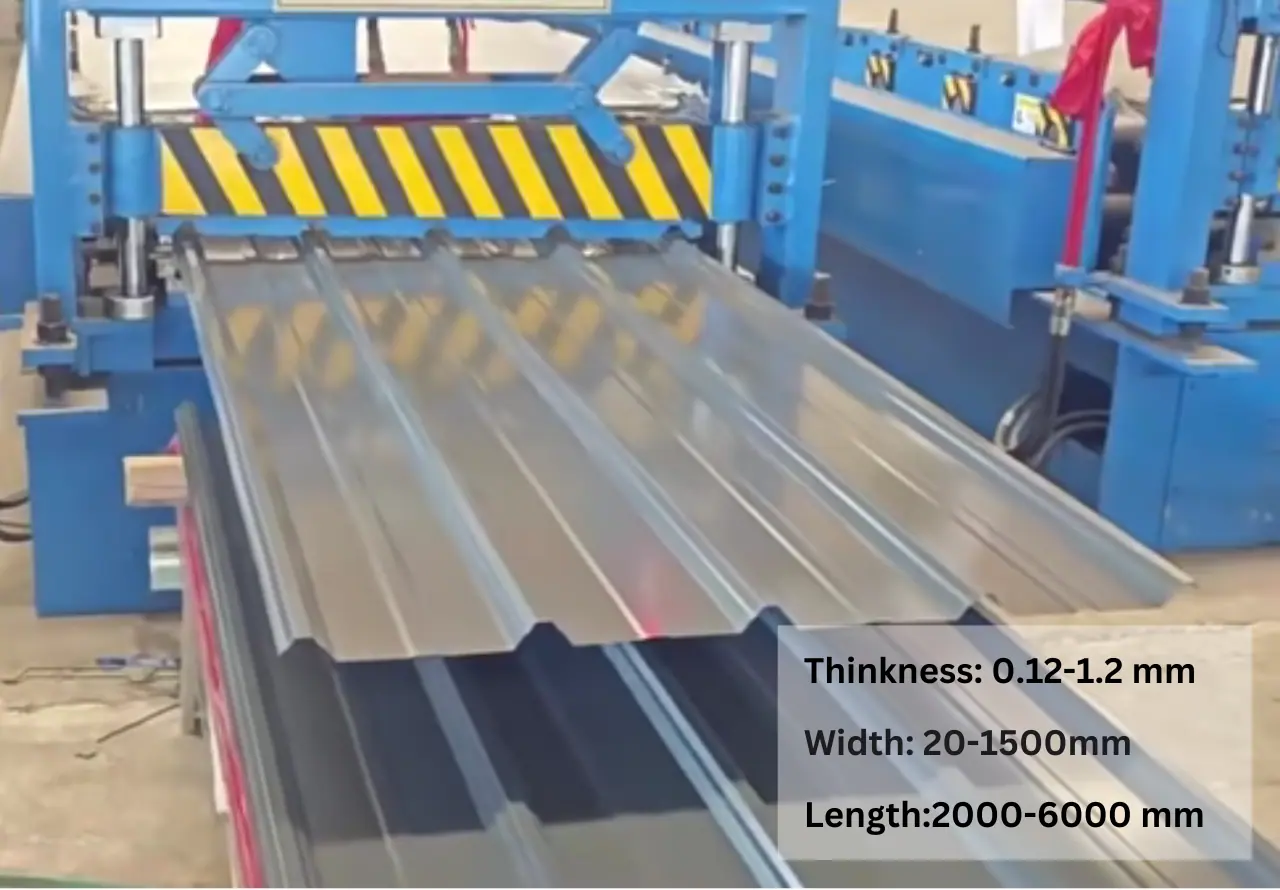

Product Specifications

Product Specifications

| Product Name | CGCC Color Galvalume Steel Roofing Sheet |

| Thickness | 0.12 mm – 1.2 mm |

| Width | 20 mm – 1500 mm |

| Normal width is 914/1000/1219/1250/1500 mm | |

| Length | 2000 mm – 6000 mm,Customized |

| Zinc Layer | 30-275 g/m² |

| Wave Width | 76 mm – 250 mm, Customized |

| Wave Height | 18 mm – 50 mm, Customized |

| Number of Peak/Valley | Customized |

| Top Coating Thickness | 15 – 25 μm |

| Back Coated Thickness | 15 – 25 μm |

| Type of coating process | Front: double coated & double drying; |

| Back: double coated & double drying; single coated & double drying; | |

| Color | According to RAL color chart, Bare, Customized |

| Edge | Mill edge, Slit edge |

| Surface Treatment | Anti-finger print, Skin pass, Oiled, Dry, Chromated, Embossed, Lamination |

| Spangle | Big, Regular, Mini, Zero |

| Certificate | IATF 16949:2016, ISO 45001, ISO 9001, ISO 14001 |

| Test | Zinc Coating Thickness Test, Bend, Cross-hatch, Salt Spray Test, Tensile Test, UV Aging Test, Temperature-Humidity Cycle, etc. |

| Tolerance | ±1% |

| Coating Material | PE, SMP, HDP, PVDF |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching, Surface Coating |

| Invoicing | By actual weight |

| Delivery Time | 7-15 days |

| Payment | T/T, L/C, Credit Card |

| Port | Shanghai, Qingdao, or according to your requirement |

| Packaging Details | In bundles, in bulk, customized packing |

Chemical Compositions

Chemical Compositions

| Element | Carbon (C) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) | Aluminum (Al) |

|---|---|---|---|---|---|---|

| Typical Composition (%) | 0.02 – 0.10 | 0.20 – 0.50 | ≤ 0.04 | ≤ 0.025 | ≤ 0.025 | ≤ 0.15 |

Mechanical properties

Mechanical properties

| Property | Typical Value |

|---|---|

| Tensile Strength (MPa) | 270 – 500 |

| Yield Strength (MPa) | 140 – 300 |

| Elongation (%) | 20 – 30 |

| Vickers Hardness (HV) | 50 – 80 |

| Brinell Hardness (HB) | 45 – 75 |

| Rockwell Hardness (HRB) | 50 – 70 |

| Elastic Modulus (GPa) | 200 |

Industries & Applications

Industries & Applications

- Residential and Commercial Roofing: Widely used in buildings for durable and weather-resistant roofing solutions.

- Wall Cladding: Applied to both interior and exterior walls for enhanced corrosion resistance and aesthetic appeal.

- Industrial Buildings and Warehouses: Suitable for large-scale structures due to its high strength and cost-effectiveness.

- Agricultural Buildings: Ideal for barns, storage sheds, and farm structures, offering protection against varying weather conditions.

- Home Appliances: Utilized in the exterior panels of appliances like refrigerators and washing machines due to its durability and rust resistance.

- Decorative and Architectural Elements: Used in facades, canopies, and awnings for both functionality and design aesthetics.

- Transportation Infrastructure: Applied in lightweight structures like shelters and enclosures for transportation stations.

Other Infomation

Other Infomation

When installing CGCC galvanized steel roof panels, following the appropriate steps can better ensure the installation quality of CGCC galvanized steel panels and extend their service life. The following is a simple and easy installation guide for your reference:

1. Preparation: First, check whether all panels and tools are intact, including screws, electric drills, sealants, etc. Accurately measure the installation area and cut the panels if necessary to ensure that each panel fits perfectly.

2. Choose the right connection method

- Overlap: Fix the panels in place by overlapping the edges, suitable for general waterproofing needs and easy installation.

- Bite edge: Buckle the edges of the panels to make the joints tighter, greatly improve the waterproofing effect, especially suitable for roofs and exterior walls.

- Buckling: Special folding treatment is performed on the edges of the panels to enhance strength and wind resistance, suitable for areas with high wind pressure.

3. Installation order: Install from the bottom of the eaves step by step upward, ensuring that the lower end of each panel is slightly tilted outward to help rainwater drain smoothly and reduce water accumulation.

4. Waterproof sealing: Use sealant or waterproof gaskets on screws, joints and edges to effectively block moisture infiltration and further improve the waterproof effect.

5. Post-completion inspection: Finally, check whether all screws and joints are tight, and clean up the metal shavings generated during the installation process to prevent scratching the surface of the board or causing rust.

Our Inventory

Our Inventory

Choosing SteelPRO Group, a galvanized steel supplier, means choosing a reliable partner. We have established long-term cooperative relationships with many world-renowned steel companies to ensure that we always maintain advantages in raw material supply and technical support. At the same time, we have advanced production lines and efficient production capacity, which can quickly respond to customer needs and meet orders of different sizes. Our factory is equipped with modern automation equipment and a strict quality management system to ensure the high quality and stability of each batch of products, so that customers can use our steel products with confidence.

Our main offerings encompass steel pipes, plates, coils, bars, strips, stainless steel series, carbon steel series, high-strength steel series, nuclear-grade steel, galvanized steel, as well as steel specifically for wind and solar energy applications, and more.

Packing

Packing

SteelPRO Group’s product packaging adopts high standards of protection measures to ensure that the steel surface is not damaged during transportation. We use moisture-proof and dust-proof outer packaging materials, and add a protective film on the inner layer to prevent friction and rust. All products are packaged in customized sizes according to customer requirements to ensure safe and stable transportation over long distances. Whether it is a full roll or cut sheets, our packaging solutions strive to deliver the product to you intact.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

How to contact us for more product information or quotation?

You can fill in the contact form on our official website or call the customer service hotline directly. Our professional team will be happy to provide you with detailed product information and quotation services.

Can SteelPRO Group provide customized services?

Yes, we can provide customized colors, sizes and surface treatments according to customer needs to meet the design requirements of different projects.

What are the after-sales services of SteelPRO Group?

We provide customers with comprehensive after-sales services, including installation support, usage consultation and product warranty to ensure customer satisfaction throughout the entire use cycle.

What is the heat resistance of CGCC galvanized steel roof panels?

Our CGCC galvanized steel sheets are specially coated to remain stable in high temperature environments, will not fade or lose structural strength easily, and are suitable for construction needs in hot areas.

Can CGCC galvanized steel roof panels be cut on the construction site?

Yes, CGCC galvanized steel sheets have good processability and can be cut and formed as needed on the construction site, while maintaining good edge protection and not easy to rust.

Will the surface coating of CGCC galvanized steel roof panels fade?

Our coatings undergo rigorous quality testing and have strong UV resistance, which allows them to maintain color stability over time under the sun and rain, reducing fading issues.

CONTACT

Certificates and Cooperation

Certificates and Cooperation