Steel Cutting

SteelPRO Group provides seven or more steel cutting methods, ensuring tailored solutions for every project. From precision cuts to heavy-duty materials, we deliver fast, reliable, and cost-effective services to meet your specific needs.

1. Laser Cutting

Advantages:

- High precision with minimal material waste.

- Clean cuts with smooth edges, reducing the need for additional finishing.

- Suitable for complex shapes and intricate designs.

- Can handle a variety of thicknesses and materials.

Cutting Size Range:

- Length: 100 mm to 12,000 mm

- Width: 100 mm to 3,000 mm

- Height: Flat sheets, typically not suitable for 3D objects

- Thickness: 0.5 mm to 30 mm (depending on material)

- Seam Width: 0.1 mm to 0.4 mm

- High Tolerance: ± 0.1 mm

- Additional Notable Limits: Laser beam width is typically less than 1 mm, allowing for intricate designs.

2. Plasma Cutting

Advantages:

- Fast cutting speeds, especially for thicker materials.

- Can cut electrically conductive metals.

- More cost-effective for thicker steel compared to laser cutting.

- Versatile in cutting different shapes and contours.

Cutting Size Range:

- Length: 50 mm to 6,000 mm

- Width: 50 mm to 3,000 mm

- Height: Flat sheets and some 3D shapes, limited complexity

- Thickness: 1 mm to 50 mm (can go up to 150 mm for specialized plasma systems)

- Seam Width: 1.5 mm to 3 mm

- High Tolerance: ± 0.5 mm

- Piercing Capacity: Plasma can pierce materials up to 40 mm thick without pre-drilling.

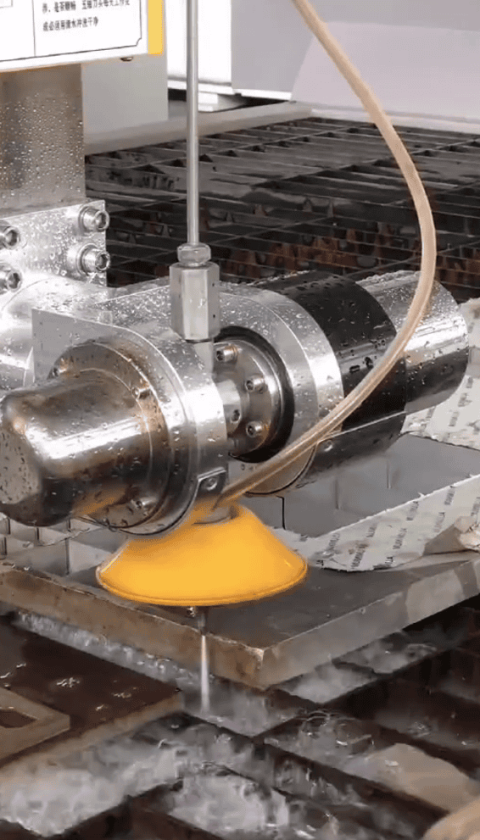

3. Waterjet Cutting

Advantages:

- No heat-affected zones, maintaining material integrity.

- Can cut virtually any material, including thick metals.

- High precision and ability to cut complex shapes.

- Environmentally friendly, using water and abrasives.

Cutting Size Range:

- Length: 100 mm to 7,000 mm

- Width: 100 mm to 4,000 mm

- Height: Suitable for both flat and contoured objects

- Thickness: 1 mm to 150 mm (up to 200 mm for softer materials)

- Seam Width: 0.8 mm to 1.2 mm

- High Tolerance: ± 0.1 mm to ± 0.2 mm

- Additional Notable Limits: Cutting angle tolerance is typically ± 1 degree for very thick materials.

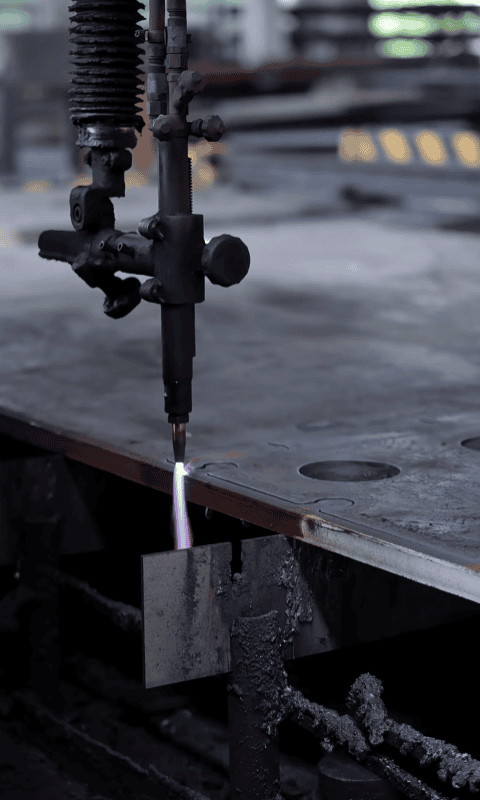

4. Flame Cutting

Advantages:

- Cost-effective for thick steel sections.

- Can cut through very thick materials.

- No requirement for electricity, making it suitable for remote sites.

- Reliable and simple to use for basic cuts.

Cutting Size Range:

- Length: 500 mm to 20,000 mm

- Width: 500 mm to 5,000 mm

- Height: Primarily for flat, thick plates

- Thickness: 6 mm to 300 mm

- Seam Width: 2 mm to 6 mm

- High Tolerance: ± 1 mm

- Heat-Affected Zone: Flame cutting results in a heat-affected zone (HAZ) ranging from 1 mm to 5 mm from the edge of the cut, which may need further processing for certain applications.

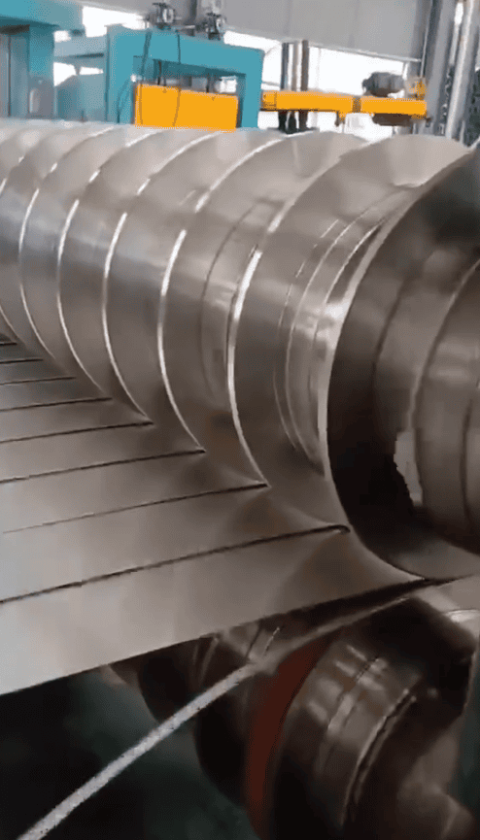

5. Shearing & Slitting

Advantages:

- High-speed cutting, ideal for mass production.

- Very clean cuts with minimal waste.

- Excellent for cutting thin steel sheets and coils.

- Minimal material distortion.

Cutting Size Range:

- Length: 100 mm to 6,000 mm (depending on coil size)

- Width: 20 mm to 2,000 mm (slitting width can be as narrow as 20 mm)

- Height: Limited to flat sheets

- Thickness: 0.5 mm to 15 mm

- Seam Width: 0.1 mm to 0.5 mm (for slitting)

- High Tolerance: ± 0.2 mm

- Slit Edge Burr: Can range from 0.1 mm to 0.5 mm, depending on material and cutting method.

6. Electrochemical Cutting

Advantages:

- Non-contact cutting method, no heat-affected zones.

- Excellent for cutting thin and delicate parts.

- No tool wear, leading to consistent quality.

- Ideal for hard metals and alloys.

Cutting Size Range:

- Length: 10 mm to 1,000 mm (for small, precision parts)

- Width: 10 mm to 500 mm

- Height: Limited to thin, flat parts or small, precise cuts

- Thickness: 0.1 mm to 10 mm

- Seam Width: Less than 1 mm

- High Tolerance: ± 0.05 mm

- Edge Roughness: Electrochemical cutting results in edge roughness of less than 10 microns, making it ideal for delicate and precision applications.

7. Milling

Advantages:

- Can create intricate 3D shapes.

- Precise control over the material removal process.

- Can be used for cutting and shaping both flat and contoured parts.

- Suitable for prototyping and small production runs.

Cutting Size Range:

- Length: 50 mm to 3,000 mm

- Width: 50 mm to 1,000 mm

- Height: Suitable for 3D shapes, depending on the machine capacity

- Thickness: 1 mm to 100 mm (based on machine and cutter capacity)

- Seam Width: Varies with the cutter size, typically 1 mm to 10 mm

- High Tolerance: ± 0.02 mm to ± 0.1 mm

- Depth of Cut: Milling can handle incremental cuts ranging from 0.5 mm to 50 mm per pass, depending on the machine settings.

Why Choose Us

Multiple Cutting Methods

Offering laser, flame, and plasma cutting for all project needs.

Efficient Delivery & Speed

Fast, efficient services for large-scale production.

Precision with No Heat Impact

Ensure precision and material integrity.

Custom Quality

Tailored services with strict quality control for top standards.

Don't be a stranger!

You tell us. We listen.

Feel free to reach out to us with any questions, concerns, or feedback. We’re here to help and ensure you have the best experience possible. Whether you’re looking for more information about our services or need support, our team is ready to assist you.