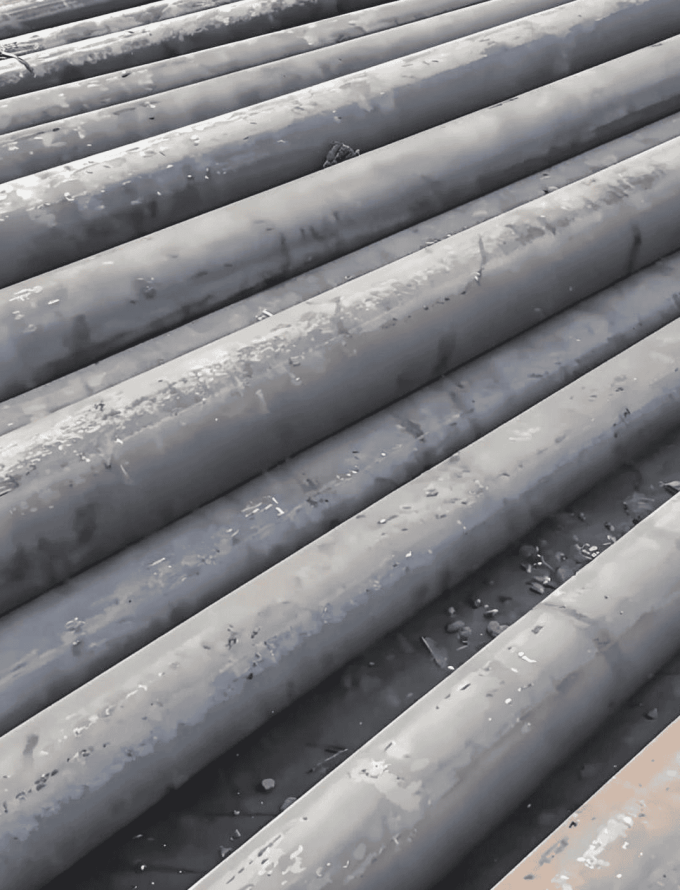

HOT ROLLED STEEL BAR

Our hot rolled steel bars are backed by a commitment to quality and supported by nationwide logistics to ensure timely delivery, all at highly competitive pricing.

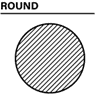

Designed to meet the demands of various industries, from construction to manufacturing, our hot rolled steel bars are available in multiple forms, including round, flat, Hexagon, and square bars. With an extensive inventory and custom processing options, we guarantee the perfect fit for your project needs.

Contact us today to learn more and request a quote tailored to your specifications.

What are Hot Rolled Steel Bars

Hot Rolled Steel Bar Type

| Type | Size Ranges | Applications | |

|---|---|---|---|

| Diameter from 1/4 inch to 12 inches | Gears, Bearings, Chain pins, Bolts | get a quote |

| Across Flats from 1/4 inch to 4 inches | Bolts and nuts, Special fasteners, Mechanical parts | get a quote |

| Side Length from 1/4 inch to 6 inches | Rails, Posts, Braces, Couplings | get a quote |

| Thickness greater than 5 mm | Support beams, Reinforcements, Railings | get a quote |

Hot Rolled Steel Bar Grades

| Standard | USA | SIZE | |

|---|---|---|---|

| ASTM A29 | 1044 | 1/4'' - 8'' | get a quote |

| ASTM A29 | 1045 | 1/4'' - 10'' | get a quote |

| ASTM A29 | 4140 | 1/4'' - 10'' | get a quote |

| ASTM A29 | 4130 | 1/4'' - 10'' | get a quote |

| ASTM A529 | Grade 50 | 1/4'' - 6'' | get a quote |

| ASTM A615 | Grade 60 | 1/4'' - 6'' | get a quote |

Quality Assurance for Hot Rolled Steel Bars

Basic Tests:

- Tensile Test: Measures yield strength, tensile strength, and elongation.

- Hardness Test: Assesses wear resistance using Brinell or Rockwell methods.

- Chemical Analysis: Ensures compliance with element content standards.

- Surface Quality Check: Inspects for cracks and surface defects.

Extreme Tests:

- Bend Test: Evaluates ductility and plastic deformation.

- Fatigue Test: Assesses cyclic loading performance.

- Cold Bend Test: Checks for cracks under cold bending.

- Metallographic Analysis: Observes microstructure.

If you have specific requirements, we can customize additional tests to meet your needs.

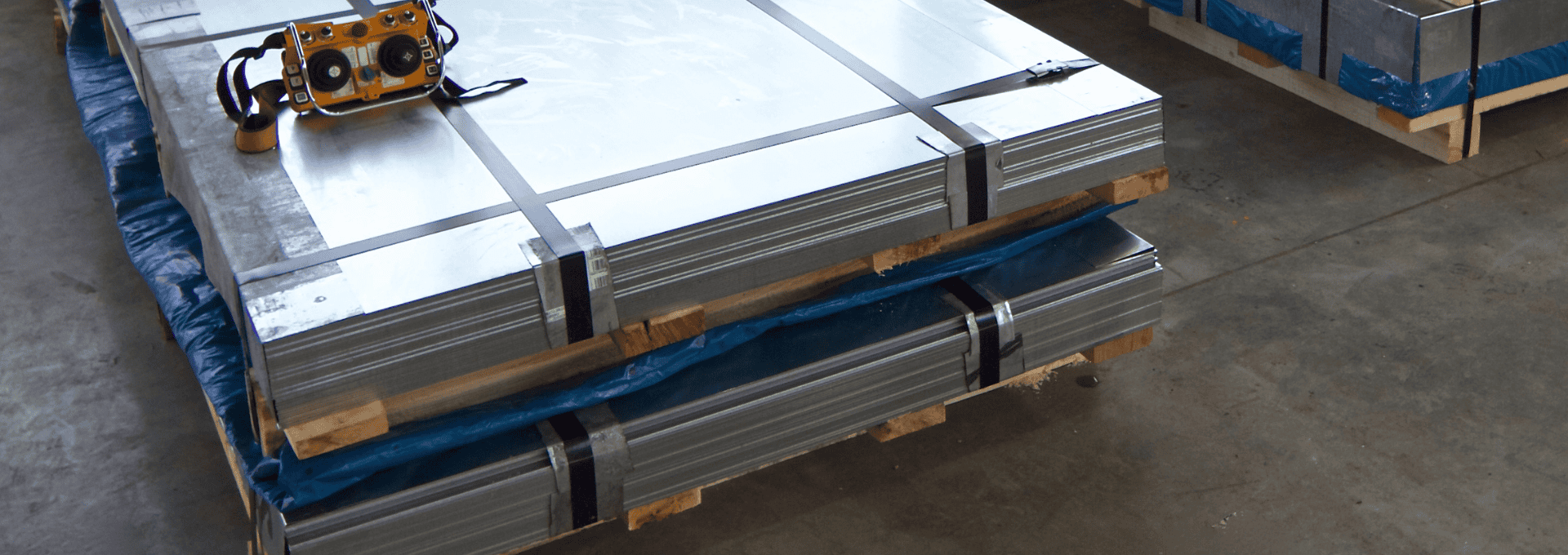

To ensure the safe and secure transportation of our steel bars, we use robust packaging methods:

-

Secured Bundling: Bars are securely bundled with steel straps and wooden supports. Finished products are shipped in wooden crates.

-

Protective Coatings: Our steel bars are coated to prevent corrosion and damage during transit. Additional coating options are available upon request.

-

Labeling and Documentation: Each shipment is clearly labeled and comes with detailed documentation for easy tracking.

Several factors influence the performance of hot rolled steel bars, affecting their suitability for various applications.

- Humidity and Corrosion: Accelerated by humidity, acids, and salts.

- Temperature Variations: High temps reduce strength; low temps increase brittleness.

- Mechanical Stress: Cyclic loads and impacts cause fatigue and cracks.

- Chemical Environment: Acids and pollutants speed up corrosion.

- Physical Damage: Scratches affect performance; coatings improve resistance.

- Storage Conditions: Poor storage accelerates corrosion; proper storage maintains quality.

Hot rolling can lead to poor surface quality and dimensional accuracy, but our advanced process ensures you need not worry about these issues.

Proper storage is vital to maintain the quality and performance of hot rolled steel bars.

- Dry Environment: Store in dry areas, preferably indoors or under cover, to avoid moisture.

- Good Ventilation: Ensure well-ventilated storage to prevent moisture buildup.

- Off-Ground Storage: Use wooden pallets or supports to keep bars off the ground.

- Categorized Storage: Store by grade, size, and shape for easy access and inventory management.

- Avoid Ground Contact: If outdoor storage is necessary, use waterproof tarps or plastic sheets.

- Temperature Control: Control temperature to avoid extreme changes.

Usage & Application of Hot Rolled Steel Bar

Hot rolled steel bars are commonly used in construction, manufacturing, and repair industries. They can be fabricated into numerous parts, such as:

- Construction Companies: Bridges, buildings, structural supports

- Automotive Manufacturers: Chassis, suspension systems, safety parts, gears, bolts

- Heavy Machinery Producers: Cranes, bulldozers, heavy equipment, machine frames

- Oil and Gas Corporations: Drilling rigs, pipelines, offshore structures, tool slides

- Aerospace Firms: Landing gear, structural components, engine parts

- Mining Companies: Drills, loaders, structural supports, mechanical components

- Metal Fabrication Shops: Brackets, frames, reinforcements, guardrails

Why Choose Our Hot Rolled Steel Bars

Our hot rolled steel bars offer superior strength, durability, and performance, crafted from premium materials to meet the highest industry standards. We provide full traceability with comprehensive documentation, ensuring authenticity and reliability. Efficient logistics guarantee timely delivery, meeting your project deadlines.

We offer a wide range of sizes, shapes, and grades, including round, square, flat, and hexagon bars, at competitive prices. Choose our hot rolled steel bars for exceptional quality, reliable documentation, prompt delivery, extensive selection, and great value. Trust us for unmatched quality and service.

Choose our hot rolled steel bars for quality, documentation, prompt delivery, selection, and competitive pricing. Trust us for excellent service.