DX54D Galvanized Steel Pipe | Tube

DX54D Galvanized Steel Pipe | Tube

SteelPRO Group provides DX54D galvanized steel pipe and a variety of galvanized steel products, including galvanized steel sheets, steel coils, steel pipes, roof panels and PPGI. With excellent anti-corrosion performance and solid structure, our DX54D Pipe is widely used in construction, machinery, automotive industry, roads, bridges, containers, sports facilities, agriculture, greenhouse construction, etc. We also provide deep processing and customization services.

- Standards: EN 10346, ASTM A653/A653M, JIS G3302, ISO 3575

- Grades: DX54D, DX54D+Z, SGCD3, G350, StE260

- Technology: Hot Dip Galvanizing, cold rolling

- Certification: ISO 9001, CE

DX54D Galvanized Steel Pipe | Tube

DX54D Galvanized Steel Pipe | Tube

Product Specifications

Product Specifications

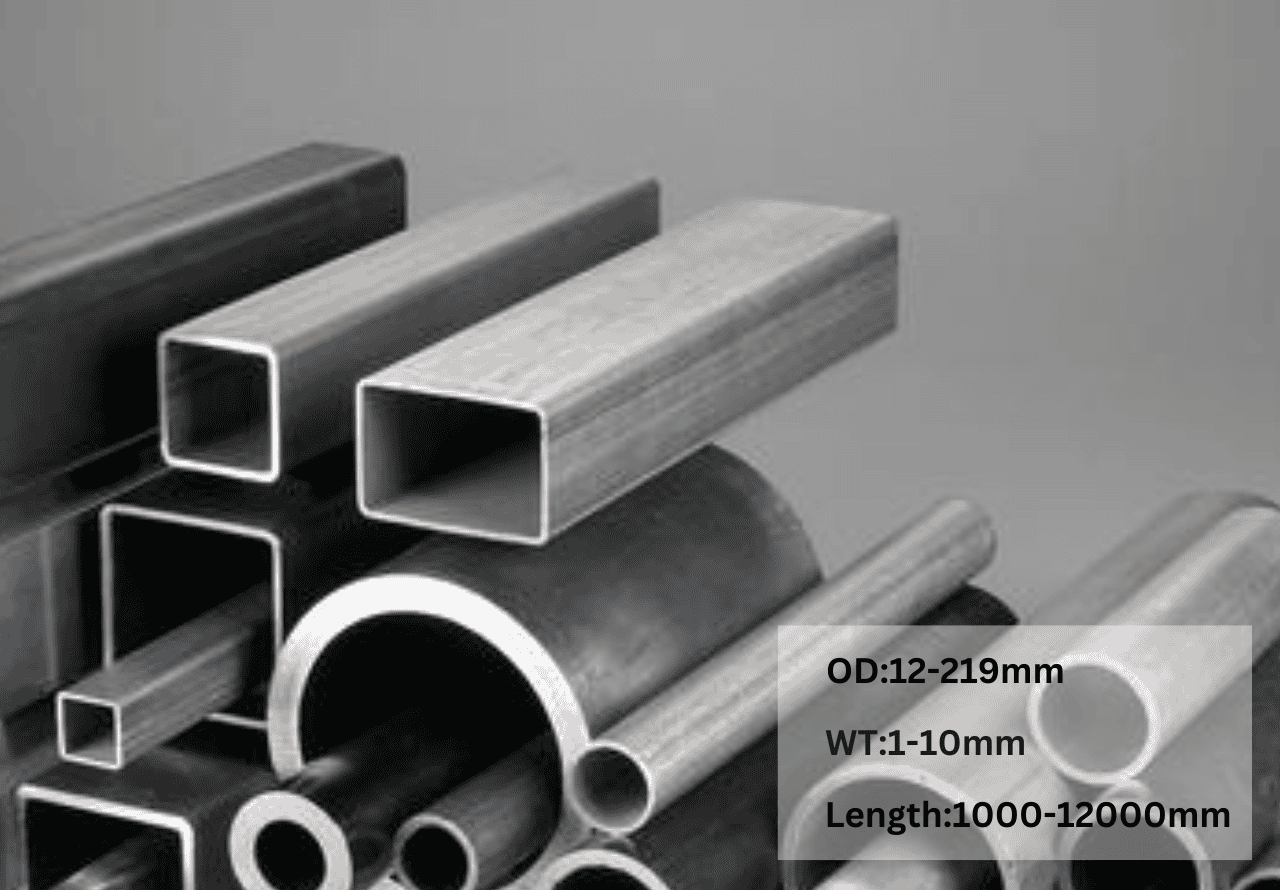

| Product Name | DX54D Hot Dip Galvanized Steel Pipe |

| WT (Wall Thickness) | 1mm – 10mm, Customized |

| OD (Outer Diameter) | 12mm – 219mm, Customized |

| Length | 1000mm – 12000mm, Customized |

| Zinc Coating | 20-400g/m², g30, g40, g60, g90, etc. |

| Surface Treatment | Anti-finger print / Skin pass / Oiled / Dry / Chromated / Embossed / Lamination |

| Spangle | Zero Spangle / Mini Spangle / Regular Spangle / Large Spangle |

| Pipe ends | Plain End, Beveled End, Threaded End, Coupled |

| Test | Zinc Coating Thickness Test, Salt Spray Test, Adhesion Test, Tensile Test, Impact Test, Bend Test, Welding Test, etc. |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Invoicing | By actual weight |

| Delivery Time | 7-15 days |

| Payment | T/T, L/C, Credit Card |

| Port | Shanghai, Qingdao or according to your requirement |

| Packaging Details | Bundled with steel strips, waterproof plastic wrap, or customized |

Chemical Compositions

Chemical Compositions

| Element | Carbon (C) | Silicon (Si) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Aluminum (Al) |

|---|---|---|---|---|---|---|

| Percentage Composition (%) | ≤ 0.08% | ≤ 0.50% | ≤ 0.40% | ≤ 0.025% | ≤ 0.020% | ≥ 0.015% |

Mechanical properties

Mechanical properties

| Property | Specification |

|---|---|

| Tensile Strength (MPa) | 270 – 370 |

| Yield Strength (MPa) | ≤ 220 |

| Elongation (%) | ≥ 38 |

| Vickers Hardness (HV) | ~ 100 – 130 |

| Brinell Hardness (HB) | ~ 50 – 70 |

| Rockwell Hardness (HRB) | ≤ 65 |

| Elastic Modulus (GPa) | ~ 210 |

Industries & Applications

Industries & Applications

- Construction industry: used for frame structures, fences, scaffolding, etc., with good corrosion resistance, suitable for outdoor use.

- Water conservancy projects: suitable for water supply and drainage pipes and underground water delivery systems, the anti-corrosion performance ensures long-term and stable use of pipes in humid environments.

- Automobile manufacturing: used in automobile exhaust systems and structural parts, with good formability and corrosion resistance.

- Home appliance industry: used for internal pipes and structures of home appliances such as washing machines and refrigerators to extend the service life of equipment.

- Agricultural facilities: suitable for greenhouse supports, livestock fences, etc., with strong weather resistance and can withstand humid and corrosive environments.

- Industrial pipelines: used to transport low-pressure liquids such as air, natural gas and oils, suitable for milder corrosive working environments.

- Power communication engineering: used for cable protection pipes and communication line brackets to ensure the stability of power and communication equipment in outdoor environments.

Other Infomation

Other Infomation

Our DX54D galvanized steel pipe can be widely used in many industries. Here are some recommendations based on different needs:

Construction industry: DX54D galvanized steel pipe is particularly suitable for outdoor applications, such as building frames, fences, and scaffolding. It has strong corrosion resistance and can cope with high humidity environments. Medium-thickness steel pipes are used for light frames, while thick-walled steel pipes are more secure for heavy-duty structures.

Automobile manufacturing: In automobiles, this type of steel pipe is widely used in chassis, exhaust systems, etc. It is strong and durable with good forming performance. Thin-walled and small-diameter pipes can be used for lightweight parts, and galvanized pipes with oiling can also improve the anti-rust effect.

Agricultural facilities: It is often used in greenhouses, irrigation pipes, fences, etc. in agriculture. It is particularly durable and suitable for long-term outdoor use. Greenhouses and fences should choose the appropriate diameter and thickness, and irrigation pipes should use pipes with a slightly larger inner diameter to ensure smooth water flow.

Household appliances: The support and piping systems in air conditioners, washing machines, and refrigerators are suitable for the use of this type of galvanized steel pipe, which is rust-proof and lasting, extending the life of home appliances. The small-diameter, thin-walled electrogalvanized pipe has a smooth and beautiful surface, which is suitable for the interior of home appliances.

Energy and Communications: This type of steel pipe is suitable for protecting cables and lines in power and communications, and is resistant to outdoor corrosion, ensuring equipment safety. Medium-thickness, thick-coated steel pipes work better and can be customized in length.

Our Inventory

Our Inventory

SteelPRO Group provides you with a full range of high-quality steel products, supporting customized services for various special needs. We have advanced production equipment and efficient automated production lines, which can flexibly respond to the needs of small to large batches. We have established a strict quality management system to ensure that each batch of products can meet international standards. At the same time, our high production capacity allows us to deliver quickly and maintain a stable supply capacity during peak periods, so you don’t have to worry about supply interruptions.

Main products: steel pipes, steel plates, steel coils, steel bars, steel strips, stainless steel series, carbon steel series, high-strength steel series, nuclear grade steel, galvanized steel, steel for wind and solar energy, etc.

Packing

Packing

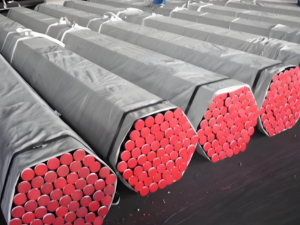

We use professional packaging methods to effectively protect product quality during long-distance transportation and storage. Each steel pipe will be uniformly bundled and reinforced according to its specifications, and fixed with high-strength steel belts to prevent the steel pipe from loosening or shifting during transportation.

We also provide customized packaging options, adding protective film, moisture-proof paper or wooden box packaging to the steel pipe according to customer needs to ensure that the product can arrive at the destination safely even in special environments. Our packaging method meets international transportation standards and is convenient for sea, air and land transportation, helping customers save transportation and warehousing costs, and ensuring that each steel pipe is delivered to the customer in the best condition.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

How do you ensure the quality stability of galvanized steel products?

We strictly follow the ISO quality management system, from raw material procurement to finished product inspection, we check every level to ensure the high quality and consistency of each batch of products.

What certifications and qualifications does your company have?

We have ISO certification and comply with many international standards such as EN and ASTM. At the same time, our products have passed environmental protection and safety tests to ensure compliance with the regulatory requirements of the global market.

What is your production capacity? Can you meet large-scale orders?

Our factory is equipped with advanced production equipment, has large-scale production capabilities, and can flexibly adjust production capacity to ensure that large-volume orders can be delivered on time during peak periods.

If you encounter problems, how do you guarantee your company's after-sales service?

We have a professional after-sales team to provide fast-response technical support and services. Whether it is a product problem or an application consultation, we will provide customers with all-round support.

What are your advantages in supply chain management?

We have a complete supply chain system, from raw material supply to finished product delivery, to ensure efficient production and stable delivery cycle, reduce customers’ waiting time and inventory pressure.

How does your company support customers' personalized needs?

We provide flexible customization services, including personalized adjustments to product specifications, packaging and transportation methods, and can make technical improvements based on customers’ special requirements to meet various project needs.

CONTACT

Certificates and Cooperation

Certificates and Cooperation