SGCC Galvanized Steel PPGI

SGCC Galvanized Steel PPGI

SteelPRO Group, as a leading galvanized steel supplier, focuses on providing high-quality SGCC PPGI products. We provide a variety of forms and shapes, including coils, plates, profiles, pipes and color-coated plates. Not only do they meet the needs of conventional industries such as construction, home appliances and automobiles, they are also widely used in special fields such as fire protection equipment. Our services include customized sizes, surface treatments and processing technology support to ensure that we provide the most suitable solutions for our customers.

- Standards: GB/T 2518, ASTM A653, JIS G3302, EN 10346, etc.

- Grades: SGCC, SPCC, DX51D+Z, CS-B, Q195, Q235

- Technology: Cold rolling, Hot dip galvanizing, Hot rolling, Pre-painted, etc.

- Substrate: Cold rolled substrate, hot rolled substrate, hot dip galvanized substrate, electro galvanized substrate

- Type: Coated, Embossed, Printed, Sheet, Coil, etc.

- Certification: ISO 9001, CE

SGCC Galvanized Steel PPGI

SGCC Galvanized Steel PPGI

- The hot-dip galvanizing process we use forms a thick zinc protective layer, which allows our SGCC PPGI to maintain a longer service life in harsh environments, especially in moisture and salt spray conditions, far superior to some brands with thin coatings.

- Our production process ensures that each roll of material has a uniform thickness and a solid structure, which means it can withstand large loads, has excellent strength and toughness, and is suitable for use as a building structure or other applications that require high load-bearing capacity.

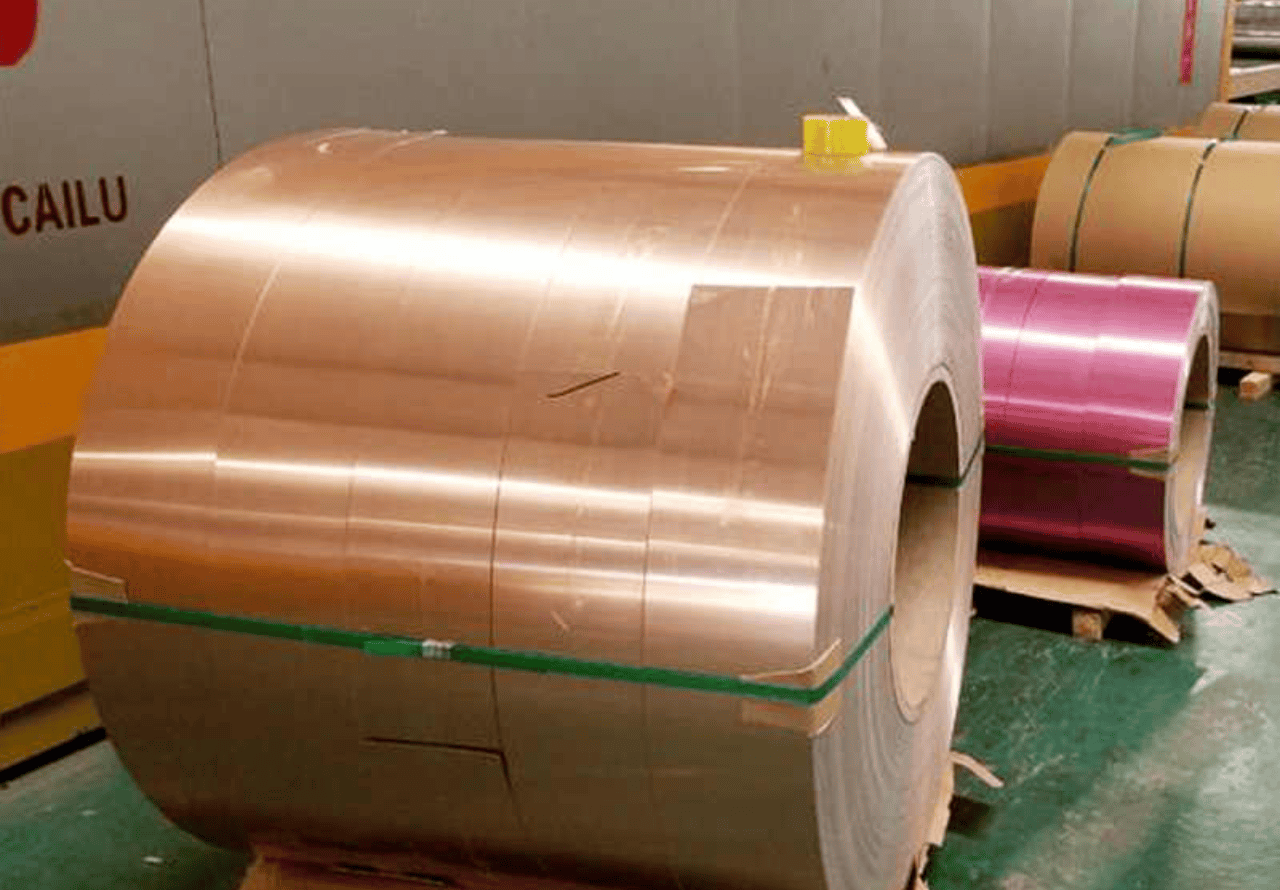

- The surface coating of PPGI provides a variety of color and texture options. It is not only beautiful, but also has good weather resistance and scratch resistance. Compared with other brands of coatings, our coating can better resist the erosion of ultraviolet rays and keep the color as long as new.

- SGCC PPGI also has good processing properties. It is easy to cut and shape, and the coating remains stable during welding, reducing losses during processing, which helps to improve production efficiency and reduce costs.

Product Specifications

Product Specifications

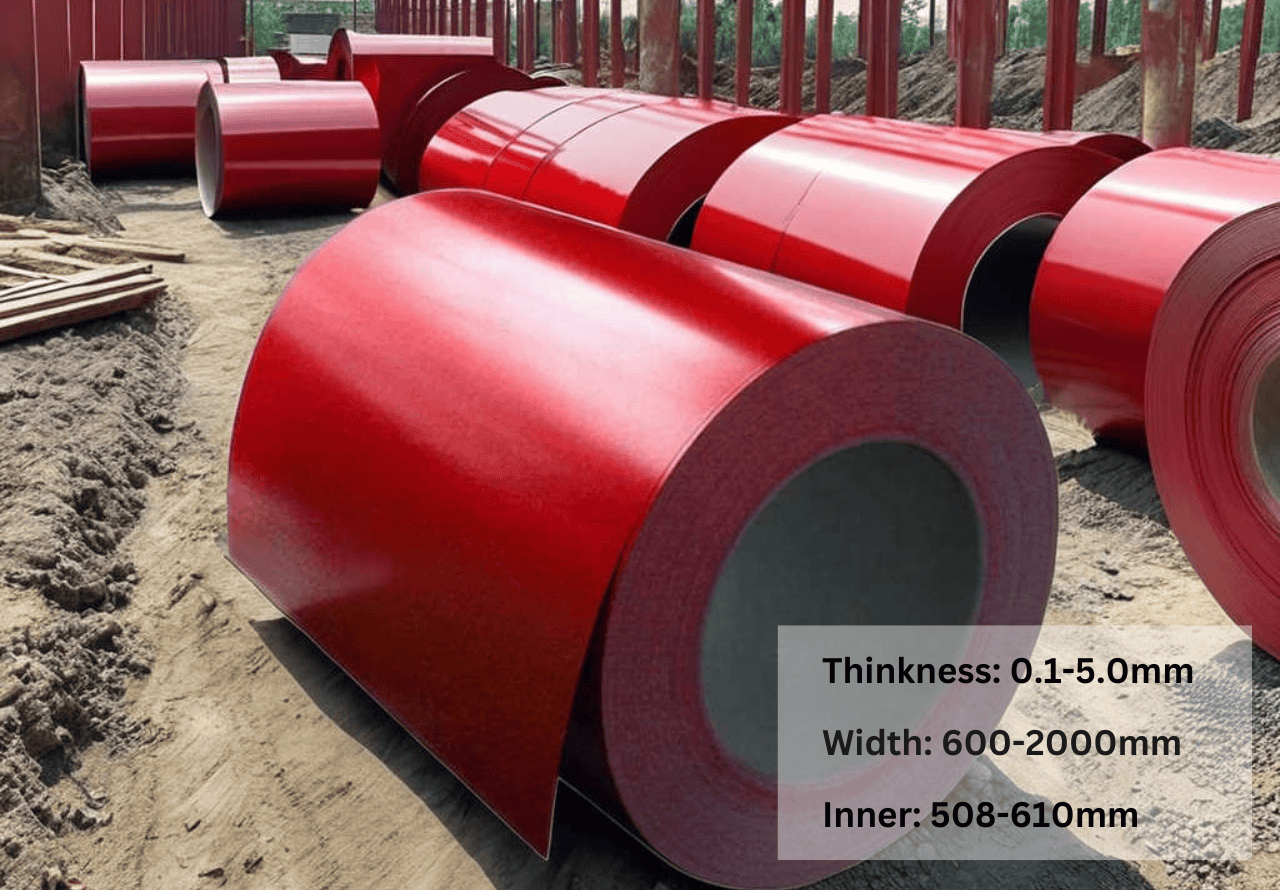

| Product Name | SGCC Color coated galvanized steel PPGI |

| Thickness | 0.1mm-5mm, Customized |

| Width | 600mm – 2000mm, Customized Regular Width: 914mm, 1000mm, 1219mm, 1220mm, 1250mm |

| Length | Customized |

| Coil Inner | 508mm – 610mm, Customized |

| Zinc Layer | 30g – 275g/m² |

| Coating Thickness | Top Coating: 15μm-25μm;

Back Coating: 5μm-20μm. |

| Surface Color | According to required RAL. |

| Coating Material | Polyester (PE), Silicone Polyester (SMP), High Durable Polyester (HDP), Fluoropolymer (PVDF) |

| Painting structure | No coating, single-sided coating, double-sided coating |

| Spangle | Big, regular, mini, and zero spangles |

| Surface Treatment | anti-finger print/skin pass/oiled/dry/chromated/Embossed/Lamination |

| Hardness | Soft (normal), hard, full hard(G300-G550) |

| T Bend | ≧ 3 T |

| Reverse Impact | ≧ 9 J |

| Salt Spray Resistance | ≧ 500 H |

| Anti-MEK Wiping | ≧ 100 Times |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Invoicing | By actual weight |

| Delivery Time | 7-15 days |

| Payment | T/T, L/C, Credit Card |

| Port | Shanghai, Qingdao or according to your requirement |

| Packaging Details | In bundles, in bulk, customized packing |

Chemical Compositions

Chemical Compositions

| Element | Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) |

|---|---|---|---|---|

| Typical Content (%) | ≤ 0.06 | ≤ 0.30 | ≤ 0.04 | ≤ 0.03 |

Mechanical properties

Mechanical properties

| Property | Value |

|---|---|

| Tensile Strength | 270 – 500 MPa |

| Yield Strength | 200 – 300 MPa |

| Elongation | 20 – 30% |

| Vickers Hardness | 80 – 140 HV |

| Brinell Hardness | 70 – 120 HB |

| Rockwell Hardness | 60 – 80 HRB |

| Elastic Modulus | 200 – 210 GPa |

Industries & Applications

Industries & Applications

- Construction Industry: Used in roofs, walls and building structures, providing good corrosion resistance and aesthetics.

- Appliances: Made into casings for various household appliances, ensuring durability and attractive appearance.

- Automotive Industry: Used in automotive body and chassis components, providing strength and corrosion resistance.

- Furniture: Made into office furniture and outdoor furniture, providing a variety of color options and designs.

- Transportation Industry: Used in exterior panels for containers and trucks, combining lightweight and aesthetics.

- Agricultural Facilities: Made into greenhouses and animal houses, providing corrosion resistance and thermal insulation.

- Industrial Equipment: Used in the manufacture of storage tanks or machinery covers that require corrosion resistance, providing protection and durable exteriors for various industrial machines.

- Signage: Used in outdoor signage due to its durability and ability to withstand adverse weather conditions.

Other Infomation

Other Infomation

Choosing SGCC PPGI is a very wise decision because it brings many benefits in long-term use.

- The durability of SGCC PPGI is excellent. It can resist corrosion and UV rays and can usually be used for more than 10 years, so you don’t need to replace it frequently, which can greatly reduce the purchase cost in the long run.

- SGCC PPGI is also easy to maintain. Due to its durability, you don’t need to spend much time and money on maintenance, which means you can save a lot of maintenance and repair costs.

- If you plan to use it on the roof, the heat-reflective properties of SGCC PPGI can help reduce the energy consumption of air conditioners, so that the monthly electricity bill will also be reduced.

- Buildings using SGCC PPGI look more attractive, which may make your property value higher, and the rental and sale prices may also be better, bringing a higher return on investment.

- SGCC PPGI meets environmental standards, which means you may also have the opportunity to obtain some tax benefits and subsidies, which will also bring you additional financial benefits.

Our Inventory

Our Inventory

When you choose SteelPRO Group, a galvanized steel manufacturer and supplier, you will experience unparalleled production capacity and industry expertise. We have advanced production lines and automated equipment with an annual production capacity of more than one million tons, which enables us to flexibly respond to orders of all sizes. At the same time, we have established solid cooperative relationships with many well-known suppliers and manufacturers to ensure that we can maintain a competitive advantage in quality, cost and delivery time. Such strong production capacity enables us to respond quickly to customer needs and provide efficient and reliable services.

Main products: steel pipes, steel plates, steel coils, steel bars, steel strips, stainless steel series, carbon steel series, high-strength steel series, nuclear grade steel, galvanized steel, steel for wind and solar energy, etc.

Packing

Packing

We use professional packaging materials and technology to ensure that every product is fully protected during transportation. Depending on the type of product, we provide customized packaging solutions, including wooden pallets, bubble wrap and moisture-proof materials to prevent damage and corrosion.

Our packaging process strictly follows industry standards to ensure efficiency and standardization, and can meet the transportation requirements of domestic and foreign customers. Whether it is a small batch order or a large batch of goods, SteelPRO Group is always committed to providing customers with safe and reliable packaging services to ensure that products arrive at their destination on time and intact.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

What are SteelPRO Group's quality control standards?

We implement strict quality control during the production process to ensure that each batch of SGCC PPGI products meets international standards and provides high-quality materials to meet customer needs.

How does SGCC PPGI perform under extreme weather conditions?

SGCC PPGI is designed to withstand extreme weather, including heat, humidity and UV rays, and can effectively maintain its structural integrity and beauty, suitable for a variety of climate conditions.

How to maintain and clean SGCC PPGI products?

In order to maintain the appearance and performance of SGCC PPGI, it is recommended to clean it regularly with mild detergent and water, avoiding the use of highly corrosive chemicals to protect the surface coating.

What is SteelPRO Group's environmental policy?

We are committed to sustainable development and adopt environmentally friendly production processes to ensure that waste and emissions are reduced throughout the production process, while using recyclable materials.

Does SteelPRO Group accept custom orders?

Yes, we welcome custom orders and can provide SGCC PPGI products in different sizes, thicknesses and colors according to customer specific needs.

How to contact SteelPRO Group for a quote?

You can fill in the inquiry form through our official website, or call our customer service hotline directly to contact our sales team, and we will provide you with a quotation and relevant information as soon as possible.

CONTACT

Certificates and Cooperation

Certificates and Cooperation