Welding

SteelPRO Group offers nine or more steel welding options, ensuring precise, durable, and customized welds for all steel types. From MIG to laser welding, we provide reliable solutions to meet your project needs.

1.Manual Metal Arc Welding (MMA)

- Welding Effect: Creates strong welds with deep penetration.

- Suitable Steels: Carbon steel, alloy steel, stainless steel.

- Post-Processing: Requires slag removal.

- Cost: Low.

- Considerations: Not ideal for thin metals. Difficult with non-ferrous metals like aluminum.

2. Gas Welding

- Welding Effect: Smooth, slow weld with good control over heat input.

- Suitable Steels: Carbon steel, alloy steel, stainless steel.

- Post-Processing: Minimal, may need cleaning.

- Cost: Moderate.

- Considerations: Not ideal for high-strength steels. Difficult to weld very thick sections.

3. Resistance Welding

- Welding Effect: Fast, strong welds with minimal deformation.

- Suitable Steels: Low-carbon steel, stainless steel.

- Post-Processing: Usually none.

- Cost: Moderate to high, but offers fast, automated processes, reducing labor costs in large-scale production.

- Considerations: Not suitable for thick materials or high-alloy steels.

4. Spot Welding

- Welding Effect: Creates localized weld points, typically for sheet metals.

- Suitable Steels: Low-carbon steel, stainless steel.

- Post-Processing: None.

- Cost: Low.

- Considerations: Best for thin sheets. Difficult with thick or high-alloy steels.

5. MIG/MAG Welding (Metal Inert/Active Gas)

- Welding Effect: Clean, fast welds with good penetration.

- Suitable Steels: Carbon steel, alloy steel, stainless steel, aluminum (with modifications).

- Post-Processing: Minimal, requires cleaning for aesthetics.

- Cost: Moderate.

- Considerations: Requires shielding gas. Not ideal for outdoor welding.

6. TIG Welding (Tungsten Inert Gas)

- Welding Effect: Precise, high-quality welds with excellent control.

- Suitable Steels: Stainless steel, carbon steel, alloy steel, aluminum.

- Post-Processing: Minimal, may need cleaning.

- Cost: High, but offers unmatched precision for critical applications like aerospace or medical industries.

- Considerations: Slow process, requires high skill. Difficult on thick materials.

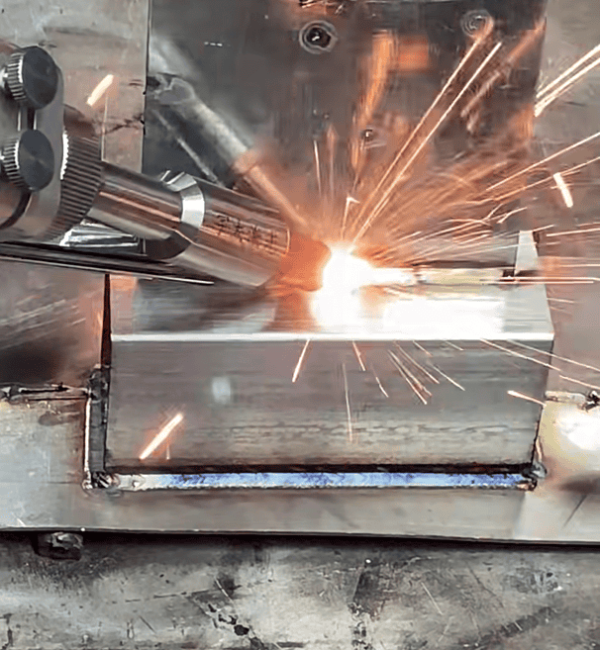

7. Laser Welding

- Welding Effect: Extremely precise welds with minimal heat distortion.

- Suitable Steels: Stainless steel, carbon steel, high-strength steel, alloy steel.

- Post-Processing: None or minimal.

- Cost: High, but reduces post-processing costs and is ideal for high-precision projects like electronics and automotive industries.

- Considerations: Expensive equipment. Not suitable for thick materials without multi-pass welding.

8. Solid-State Welding

- Welding Effect: Produces strong bonds without melting the material.

- Suitable Steels: Carbon steel, alloy steel, stainless steel.

- Post-Processing: Usually none.

- Cost: High, but delivers stronger, more durable welds without heat-related issues, suitable for high-performance applications.

- Considerations: Requires precise control. Not suitable for very thick or brittle materials.

Our Testing

We use destructive and non-destructive testing to ensure welds are defect-free, meet stress and deformation standards, and have proper HAZ properties.

- Visual Inspection: Identifies visible defects like cracks, undercut, and porosity.

- Ultrasonic Testing (UT): Uses sound waves to detect internal flaws such as cracks and voids.

- Radiographic Testing (RT): X-ray testing reveals internal defects like gas inclusions and lack of fusion.

- Magnetic Particle Testing (MT): Uses magnetic fields to detect surface and near-surface defects in ferromagnetic materials.

- Dye Penetrant Testing (PT): Dye highlights surface cracks or defects, used for non-magnetic materials.

- Destructive Testing (DT): Measures weld strength and toughness by applying mechanical stress, ensuring real-world durability.

Why Choose Us for Steel Welding

- Expert Welding Techniques

We offer a wide range of welding methods tailored to your specific project needs, ensuring strong, precise, and high-quality welds for any type of steel. - Comprehensive Testing

Our stringent testing, using both destructive and non-destructive methods, ensures every weld meets top safety and quality standards, minimizing defects. - Experienced Team

With a highly skilled team, we deliver accurate and reliable welding, even for complex projects, ensuring durability and performance. - Cost-Effective Solutions

We provide high-quality welding services while optimizing costs through efficient processes, ensuring you get the best value without compromising quality.

Choosing us means partnering with experts committed to delivering strong, defect-free welds that stand up to demanding applications.

Welding Steel General Numerical Range

The following is a table of general ranges of values for various parameters related to steel welding, and cannot be used as reference values for other companies.

| Parameter | Range | Units |

|---|---|---|

| Weld Thickness | 0.5 mm to 100 mm | Millimeters (mm) |

| Weld Length | 10 mm to 12,000 mm | Millimeters (mm) |

| Welding Current (MIG) | 50 A to 600 A | Amperes (A) |

| Welding Voltage (MIG) | 15 V to 40 V | Volts (V) |

| Welding Speed (MIG) | 200 mm/min to 500 mm/min | mm/min |

| Weld Penetration Depth | 0.5 mm to 20 mm | Millimeters (mm) |

| Heat Input | 0.5 kJ/mm to 5.0 kJ/mm | Kilojoules/mm (kJ/mm) |

| Shielding Gas Flow Rate | 10 L/min to 25 L/min | Liters/min (L/min) |

| Preheat Temperature | 100°C to 300°C | Degrees Celsius (°C) |

| Post-Weld Cooling Rate | 50°C/hr to 150°C/hr | Degrees Celsius/hour (°C/hr) |

FAQ

What is the easiest way to weld steel?

MIG welding is the easiest due to its simple setup and ease of use.

What is the best welding for steel?

TIG welding offers the highest precision and clean welds, but MIG is best for speed and versatility.

Can you weld two different grades of steel together?

Yes, but the right filler material and technique are crucial for a strong bond.

What metal cannot be welded?

Metals like cast iron and certain alloys are difficult or impossible to weld effectively.

Which welding method is best for my steel type?

We recommend different methods based on steel type: MIG for carbon steel, TIG for stainless steel, and laser for high precision.

How do you ensure the weld quality?

We use destructive and non-destructive testing methods to ensure defect-free, durable welds.

Can you handle high-volume welding orders?

Yes, our advanced equipment and experienced team allow us to manage large-scale welding projects efficiently.

What are the costs for different welding methods?

Costs vary by method. MIG and MMA are cost-effective, while TIG and laser welding are higher-cost due to precision.