Electro Galvanized Steel Wire

Electro Galvanized Steel Wire

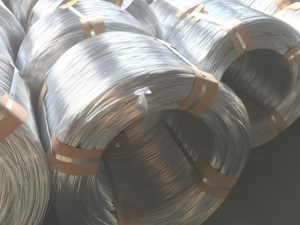

SteelPRO Group is an electro-galvanized steel wire supplier and manufacturer with various sizes and specifications to choose from to meet different application needs. Our products are manufactured using advanced electro-galvanizing technology to ensure excellent corrosion resistance and durability. We provide customized processing services such as cutting and straightening. With reliable delivery time and flexible payment methods, SteelPRO Group also provides hot-dip galvanized steel wire, steel sheets, coils, tubes, PPGI, roofing sheets, etc. to support your construction, industrial and DIY projects.

- Standards: ASTM A641, ISO 9001, etc.

- Grades: Q195, Q235, G450, G550, etc.

- Wire gauge: 8-24 gauge, 14 gauge, 16 gauge, 12 gauge, etc.

- Technology: Electro Galvanizing, Cold Drawing

- Special Use: Communication equipment, medical equipment and brushes, cables, filters, high-pressure pipelines, etc.

- Form: Coil, Spool, Rope, Mesh

- Certification: ISO 9001, CE

Electro Galvanized Steel Wire

Electro Galvanized Steel Wire

Product Specifications

Product Specifications

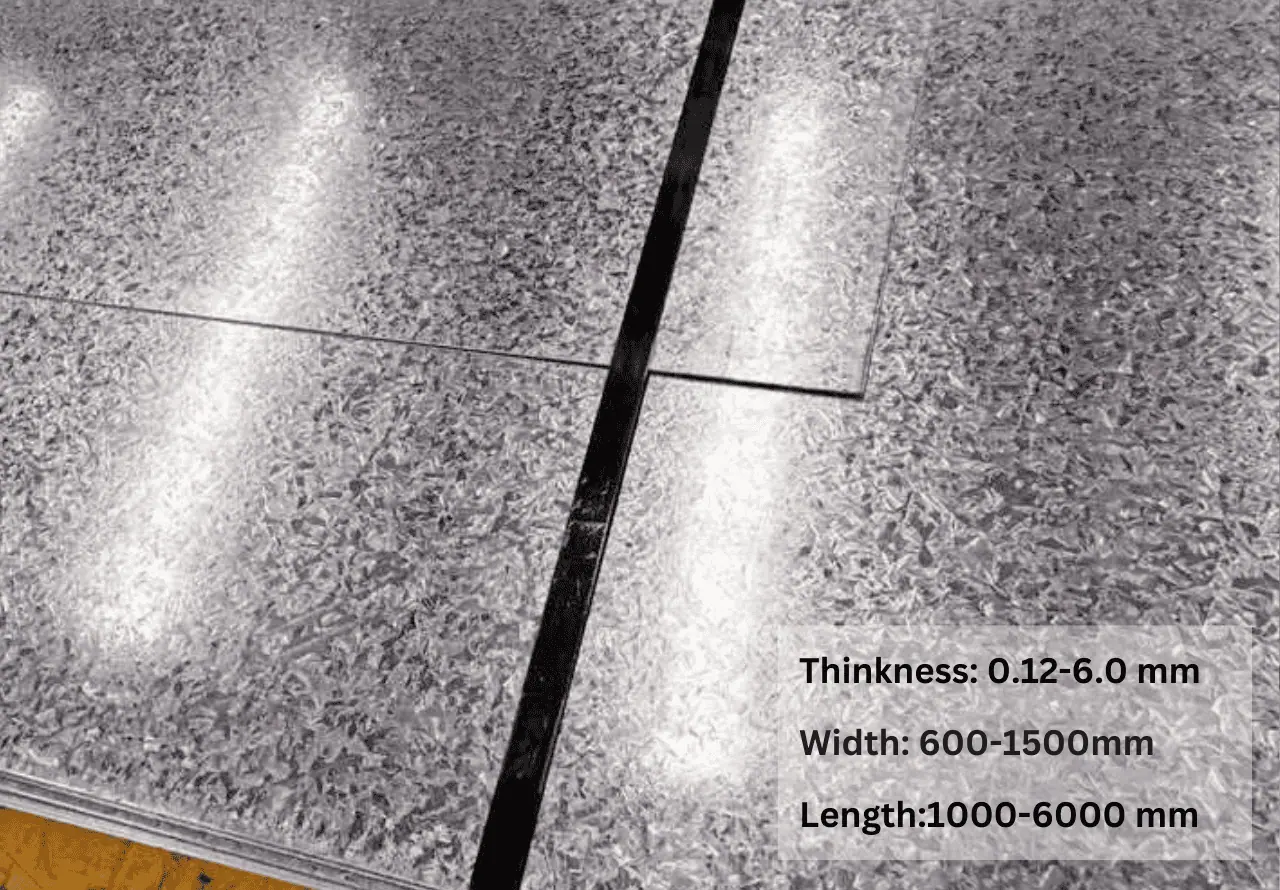

| Product Name | Electro Galvanized Steel Wire | ||

| Wire Diameter | 0.15mm – 8.00mm | ||

| Wire Coil Weight | 20-1200kg | ||

| Wire Coil Length | Varies by coil weight, common lengths include 100 m, 200 m, 300 m, Customized | ||

| Coil Outer Diameter | 800 – 1200 mm | ||

| Coil Inner Diameter | 400 – 600 mm | ||

| Zinc Layer | 20-400g/m², g30, g40, g60, g90, etc. | ||

| Elongation | ≥10% | ||

| Tensile strength | 350–700 MPa | ||

| Load strength | 150 – 1200 N | ||

| Coating Material | Polyester (PE), Silicone Polyester (SMP), High Durable Polyester (HDP), Fluoropolymer (PVDF) | ||

| Surface Treatment | anti-finger print/skin pass/oiled/dry/chromated/Embossed/Lamination | ||

| Test | Zinc Coating Thickness Test, Adhesion Test, Peel, Bend, Salt Spray Test, Tensile Test, Elongation, etc. | ||

| Tolerance | ±1% | ||

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching | ||

| Invoicing | By actual weight | ||

| Delivery Time | 7-15 days | ||

| Payment | T/T, L/C, Credit Card | ||

| Port | Shanghai, Qingdao or according to your requirement | ||

| Packaging Details | In bundles, in bulk, customized packing | ||

Chemical Compositions

Chemical Compositions

| Element | Carbon (C) | Silicon (Si) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) |

|---|---|---|---|---|---|

| Typical Percentage (%) | 0.05 – 0.30 | 0.10 – 0.50 | 0.30 – 0.90 | ≤ 0.04 | ≤ 0.04 |

Mechanical properties

Mechanical properties

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 350 – 600 |

| Yield Strength (MPa) | 250 – 450 |

| Elongation (%) | 10-20 |

| Vickers Hardness (HV) | 100 – 200 |

| Brinell Hardness (HB) | 100 – 180 |

| Rockwell Hardness (HRB) | 60 – 90 |

| Elastic Modulus (GPa) | 200 – 210 |

Industries & Applications

Industries & Applications

- Electrical Applications: Galvanized steel wire is commonly used in electrical connections and conductors, providing good electrical conductivity and corrosion resistance.

- Fencing and Security: Used to build fences and security barriers to protect farmland, commercial properties and residential areas.

- Agricultural Support: Suitable for supporting plants, crops and trellises due to its lightness and high strength.

- Construction Tie Wire: In construction, galvanized steel wire is used to fix rebar and reinforce structures to ensure stability.

- Packaging and Bundling: Widely used in the packaging and transportation industry to bundle materials for safe transportation.

- Automotive Industry: Used in automotive connectors and wiring harnesses to meet corrosion resistance and strength requirements.

- Craft and Decorative Uses: Suitable for handicrafts and DIY projects, making decorations and lightweight structures.

- Special Engineering Applications: Used to connect and fix equipment in some highly corrosive environments (such as chemical plants and marine facilities).

Other Infomation

Other Infomation

To distinguish between electrogalvanized steel wire and hot-dip galvanized steel wire, you can use the following simple methods:

- Observe the appearance: the surface of electrogalvanized steel wire is smooth and bright, while the surface of hot-dip galvanized steel wire is rough and matte zinc gray.

- Check the thickness of the zinc layer: the zinc layer of electrogalvanized steel wire is thinner and suitable for slightly humid environments; the zinc layer of hot-dip galvanized steel wire is thicker and suitable for humid or harsh environments.

- Touch and scratch: the zinc layer of electrogalvanized steel wire is fragile and easy to scratch off; the zinc layer of hot-dip galvanized steel wire is stronger and less susceptible to damage.

When choosing, please consider the following points:

- Use environment: choose hot-dip galvanizing in humid or outdoor environments, and electrogalvanizing in indoor or dry environments.

- Load requirements: choose hot-dip galvanizing when carrying large loads, and electrogalvanizing is suitable for lighter loads.

- Processing requirements: electrogalvanized steel wire is easier to process and is suitable for electrical connections and DIY projects; hot-dip galvanizing is more durable.

- Budget: Electro-galvanized steel wire is cheaper and suitable for projects with limited budgets; hot-dip galvanizing, although slightly more expensive, is more cost-effective in the long run.

We at SteelPRO Group offer high-quality electro-galvanized steel wire and hot-dip galvanized steel wire to meet your various needs. If you have any questions, please feel free to ask us!

Our Inventory

Our Inventory

SteelPRO Group uses advanced manufacturing facilities, cutting-edge technology and automated production lines to ensure high efficiency and consistent quality. With a skilled workforce committed to strict quality control, we maintain high standards at every stage of production. Our strategic partnerships increase our supply chain efficiency, allowing us to quickly meet high-demand orders. We are committed to innovation and sustainability, providing galvanized steel solutions that meet the changing needs of our customers.

Main products: Electro galvanized steel wire, steel pipes, steel plates, steel coils, steel bars, steel strips, stainless steel series, carbon steel series, high-strength steel series, nuclear grade steel, galvanized steel, steel for wind and solar energy, etc.

Packing

Packing

At SteelPRO Group, we ensure that all our products are carefully packed to prevent damage during transportation. Our packaging is designed to withstand various shipping conditions while maintaining the integrity of the materials. We utilize durable materials and methods to ensure safe delivery to our clients. Our products are exported to regions including the Middle East, South America, Africa, Southeast Asia, and others, reflecting our commitment to serving a global market with high-quality galvanized steel solutions.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

How to store electrogalvanized steel wire to maintain its quality?

To maintain the quality of electrogalvanized steel wire, it is recommended to store it in a dry, ventilated environment, away from moisture and direct exposure to sunlight to prevent the zinc layer from being damaged.

What is the applicable temperature range of electrogalvanized steel wire?

Electrogalvanized steel wire performs best at room temperature and is recommended to be used in an environment not exceeding 200°C to avoid the zinc layer losing its protective effect.

How does SteelPRO Group respond to customer feedback?

We value the feedback of every customer and have a dedicated team responsible for collecting and processing customer opinions. We will continuously improve our products and services based on customer suggestions to meet customer needs.

How much load can electrogalvanized steel wire withstand?

The load-bearing capacity of electrogalvanized steel wire depends on its diameter and application. Generally speaking, the larger the wire diameter, the stronger the load-bearing capacity and is suitable for a variety of different applications.

How to judge the quality of electrogalvanized steel wire?

The quality of electrogalvanized steel wire can be evaluated by checking the uniformity and smoothness of the zinc layer as well as the tensile strength. The zinc layer of our products is uniform and strong, ensuring long-term use.

What delivery options does SteelPRO Group offer?

We offer a variety of delivery options, including standard shipping and expedited delivery, to meet our customers’ needs. Specific delivery times depend on order volume and destination.

CONTACT

Certificates and Cooperation

Certificates and Cooperation