DX53D Galvanized Steel Pipe | Tube

DX53D Galvanized Steel Pipe | Tube

As a galvanized steel pipe manufacturer and supplier, SteelPRO Group offers a wide range of DX53D Gi pipes, including round pipes, square pipes, hot-dip galvanized and electro-galvanized steel pipes, suitable for a variety of applications such as building structures, fluid transportation, wire casings, etc. Our products have excellent corrosion resistance and comply with EN, JIS, GB and other standards. We also provide processing services such as cutting, bending, welding, punching, and other grades and types of steel such as dx51d to meet customers’ customized needs.

- Standards: EN 10346, DIN 17162, JIS G3302, ASTM A653/A653M

- Grades: DX53D, DX53D+Z, SGCC, G3452, FS Type A/B

- Technology: Hot Dip Galvanizing, Cold rolling

- Certification: ISO 9001, CE

DX53D Galvanized Steel Pipe | Tube

DX53D Galvanized Steel Pipe | Tube

Product Specifications

Product Specifications

| Product Name | DX53D Hot Dip Galvanized Steel Pipe |

| WT (Wall Thickness) | 1mm – 10mm, Customized |

| OD (Outer Diameter) | 12mm – 219mm, Customized |

| Length | 1000mm – 12000mm, Customized |

| Zinc Coating | 20-400g/m², g30, g40, g60, g90, etc. |

| Surface Treatment | Anti-finger print / Skin pass / Oiled / Dry / Chromated / Embossed / Lamination |

| Spangle | Zero Spangle / Mini Spangle / Regular Spangle / Large Spangle |

| Pipe ends | Plain End, Beveled End, Threaded End, Coupled |

| Test | Zinc Coating Thickness Test, Salt Spray Test, Adhesion Test, Tensile Test, Impact Test, Bend Test, Welding Test, etc. |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Invoicing | By actual weight |

| Delivery Time | 7-15 days |

| Payment | T/T, L/C, Credit Card |

| Port | Shanghai, Qingdao or according to your requirement |

| Packaging Details | Bundled with steel strips, waterproof plastic wrap, or customized |

Chemical Compositions

Chemical Compositions

| Element | Carbon (C) | Silicon (Si) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Aluminum (Al) | Nitrogen (N) |

|---|---|---|---|---|---|---|---|

| Content (%) | ≤ 0.12 | ≤ 0.50 | ≤ 0.60 | ≤ 0.10 | ≤ 0.045 | ≥ 0.015 (for deoxidation) | ≤ 0.012 |

Mechanical properties

Mechanical properties

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 270 – 370 |

| Yield Strength (MPa) | ≥ 140 |

| Elongation (%) (for thickness ≤ 0.7 mm) | ≥ 26 |

| Elongation (%) (for thickness > 0.7 mm) | ≥ 30 |

| Vickers Hardness (HV) | Approx. 90 – 120 |

| Brinell Hardness (HB) | Approx. 70 – 100 |

| Rockwell Hardness (HRB) | ≤ 70 |

| Elastic Modulus (GPa) | Approx. 210 |

Industries & Applications

Industries & Applications

Building and Infrastructure

- Used for building scaffolding, support structures, guardrails and fences, with good strength and corrosion resistance.

- Widely used in steel structure buildings, bridges, sheds and frame structures.

Fluid transportation

- Suitable for conveying fluids such as water, oil, and gas. The galvanized coating inside and outside the pipe can prevent corrosion.

- Commonly used in scenes such as industry, agricultural irrigation, and urban water supply systems.

Cable protection

- Used as a protective sleeve for wires and cables to prevent damage to the cables from the external environment.

- Suitable for underground cable laying, building electrical installation and other fields.

Home appliances and furniture manufacturing

- Used to make components for home appliances such as washing machines, refrigerators, and air conditioners to extend the service life of the products.

- Make furniture such as tables, chairs, bed frames, and shelves, which are both beautiful and durable.

Agricultural equipment

- Used for greenhouse frames, agricultural machinery and equipment, irrigation pipes, etc., to resist moisture and corrosion.

- Suitable for the construction and maintenance of various agricultural facilities.

Transportation

- Can be used for exhaust pipes and other parts in automobile manufacturing because of its corrosion resistance and good processing performance.

- Used for protective railings on roads and bridges and railway signal equipment.

Outdoor facilities

- Outdoor guardrails, light poles, bicycle racks and other equipment in parks and squares.

- Suitable for long-term use in harsh weather environments and has good weather resistance.

Other Infomation

Other Infomation

At SteelPRO Group, we subject our DX53D galvanized steel pipes to stringent quality controls, consistently meeting high standards for durability, reliability, and performance in a wide range of applications.

Raw material inspection: We start with high-grade steel coils, ensuring the chemical composition is up to standard, with carbon content ≤0.12% and manganese content ≤0.60%. Surface defects are also checked to guarantee smooth processing.

Zinc coating thickness testing: We use micrometers and magnetic gauges to ensure uniform coating thickness, ranging from 60 g/m² to 275 g/m². Thicker coatings are particularly suitable for outdoor and coastal environments, providing superior corrosion protection.

Tensile and yield strength testing: The pipes have a tensile strength between 270 MPa and 370 MPa, with a minimum yield strength of 140 MPa. This ensures that the pipes can withstand mechanical stress without deformation, making them suitable for structural and industrial applications.

Impact and elongation testing: Impact and elongation testing confirms the pipes’ ability to withstand sudden shocks, especially at low temperatures. We also check for elongation of ≥ 26% (thickness ≤ 0.7 mm) and ≥ 30% (thickness > 0.7 mm), ensuring good ductility for forming and bending.

Dimensional accuracy and surface inspection: We continuously monitor the outer diameter (± 0.5%), wall thickness (± 0.2 mm) and length (± 10 mm). Surface inspection ensures a smooth and uniform surface without dents, uneven coating or defects.

Corrosion resistance verification: Using salt spray testing, we simulate prolonged exposure to a corrosive environment. Pipes that maintain integrity in the salt spray test for more than 96 hours are confirmed to have a strong and durable coating that ensures long-term rust protection.

Our Inventory

Our Inventory

SteelPRO Group’s strict quality control during the production process ensures accurate dimensions, consistent thickness and excellent surface finish, reducing problems during installation. We carry a large stock of standard sizes and can quickly fill orders. An efficient logistics team ensures on-time delivery, even for custom orders.

Main products: steel pipes, steel plates, steel coils, steel bars, steel strips, stainless steel series, carbon steel series, high-strength steel series, nuclear grade steel, galvanized steel, steel for wind and solar energy, etc.

Packing

Packing

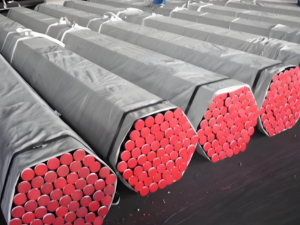

To ensure safe and secure delivery, SteelPRO Group uses the following packaging methods for DX53D galvanized steel pipes:

- Bundling and securing: The pipes are bundled with durable steel straps to ensure they remain intact during transportation. The bundles are securely secured to prevent shifting and damage.

- Waterproof packaging: Each bundle is wrapped with waterproof plastic film to protect against moisture and dust. Additional protective covers are available upon request.

- End protection: Plastic caps are placed on the ends of the pipes to prevent contamination and protect the threads (if applicable).

- Customized packaging: Options such as wooden pallets or special labels are available upon specific request to ensure easy handling and identification.

- Clear labeling: Each bundle is marked with size, length and batch information for efficient inventory management.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

What are the benefits of using DX53D galvanized steel pipes?

DX53D galvanized steel pipes offer excellent corrosion resistance, durability, and flexibility for a variety of applications such as construction, fluid transfer, electrical conduits, and agricultural equipment. They are also easy to process and install.

How long does the zinc coating on DX53D pipes last?

The lifespan of the zinc coating depends on the environment. In suburban or less corrosive environments, the coating can last for more than 50 years without noticeable rusting. In industrialized or coastal areas, it can provide effective protection for up to 20 years.

Can SteelPRO Group customize DX53D galvanized steel pipes?

Yes, we offer custom options for size, wall thickness, length, and surface treatment. We also offer additional processing services such as cutting, bending, welding, and drilling to meet your specific requirements.

What is the difference between hot-dip galvanized and electro-galvanized pipes?

Hot-dip galvanized pipes (like our DX53D) have a thicker, more durable zinc coating that provides better protection against corrosion, making them suitable for outdoor and heavy-duty use. Electro-galvanized pipes have a thinner coating and are primarily used indoors or in low-corrosion environments.

How does SteelPRO Group ensure the quality of DX53D galvanized steel pipes?

We follow strict quality control measures throughout the manufacturing process, including precise monitoring of zinc coating thickness and mechanical properties. Our pipes meet international standards, ensuring consistent performance and reliability.

What is the typical lead time for a DX53D galvanized steel pipe order?

Standard lead time is 15-30 days after order confirmation, depending on quantity and customization requirements. We work closely with our logistics partners to ensure timely and efficient delivery.

CONTACT

Certificates and Cooperation

Certificates and Cooperation