DH40 | High-Strength Shipbuilding Steel

DH40 | High-Strength Shipbuilding Steel

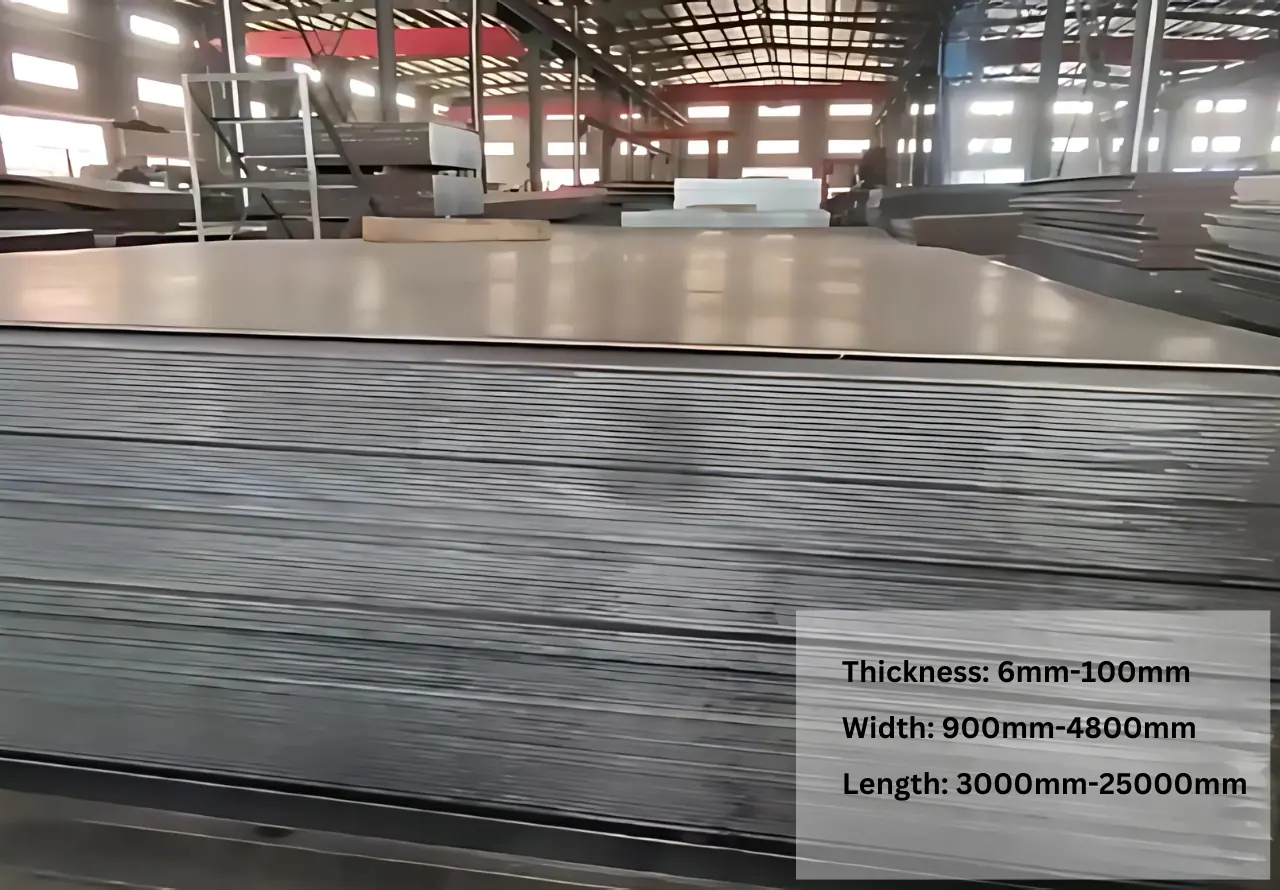

SteelPRO Group provides DH40 high-strength shipbuilding steel plates in stock.

Class Cert.: ABS/BV/CCS/DNV/KR/LR/NK/RINA/RS/PRS

Material: Low Alloy Steel

Thickness: 6mm-100mm, or customized

Width: 900mm-4800mm, or customized

Length: 3000mm-25000mm, or customized

Condition of Delivery: A/HR/N/CR/Q+T/TMPC, or as request

Stock: In stock

Origin: Hebei/Henan/Jiangsu, China

Port: Qingdao

Looking for other Grade 40 high-strength steel?

Click here for AH40/EH40/FH40.

Description

What Is DH40?

DH40 steel is a high-strength structural steel used in marine and offshore engineering. It primarily consists of iron, carbon, and manganese, with microalloying elements added to enhance durability. “D” stands for toughness level at -20℃, “H” indicates high-strength steel, and “40” for a minimum yield strength of 390Mpa.

The key features of DH40 steel include high yield and tensile strength, enabling it to withstand high-stress environments. It offers excellent toughness for low-temperature impact resistance and good corrosion resistance, making it suitable for harsh marine conditions. Additionally, its low-carbon equivalent ensures easy weldability, which is essential for large-scale construction.

DH40 steel is widely used in shipbuilding, including hulls, decks, and bulkheads. It is also utilized in offshore platforms, bridge structures, and heavy machinery, making it ideal for demanding environments and complex engineering applications.

Characteristics of DH40

- High strength for heavy-duty applications

- Excellent toughness, even at low temperatures

- Good wear resistance under tough conditions

- Resistant to cracking under stress

- Good machinability and weldability

Chemical Compositions

| Element | Content (%) |

|---|---|

| Carbon, C | ≤ 0.18 |

| Silicon, Si | ≤ 0.50 |

| Manganese, Mn | 0.90-1.60 |

| Phosphorus, P | ≤ 0.035 |

| Sulfur, S | ≤ 0.035 |

| Aluminium, Als | ≥ 0.015 |

| Titanium, Ti | ≤ 0.02 |

| Copper, Cu | ≤ 0.35 |

| Chromium, Cr | ≤ 0.20 |

| Nickel, Ni | ≤ 0.40 |

| Molybdenum, Mo | ≤ 0.08 |

| Niobium, Nb | 0.02-0.05 |

| Vanadium, V | 0.05-0.10 |

Physical Properties

| Property | Metric Value | Imperial Value |

|---|---|---|

| Density | 7.85 g/cm³ | 0.284 lb/in³ |

| Melting Point | 1510°C | 2750°F |

| Thermal Conductivity | 50.2 W/m·K | 29.05 BTU/(hr·ft·°F) |

| Electrical Conductivity | 3.1 MS/m | 1.8 x 10^6 S/ft |

| Specific Heat Capacity | 480 J/kg·K | 0.115 BTU/(lb·°F) |

| Thermal Expansion Coefficient | 11.7 µm/m·°C | 6.5 µin/in·°F |

| Electrical Resistivity | 0.65 µΩ·m | 25.6 µΩ·in |

Mechanical Properties

| Thickness (mm) | Yield Strength (MPa min.) | Tensile Strength (MPa) | Elongation (% min.) | Test Temperature (°C) | Impact Energy (KV J min.) Transverse/Longitudinal |

|---|---|---|---|---|---|

| ≤50 | 390 | 510 – 650 | 20 | -20 | 27/41 |

Industries & Applications

| Industry | Application |

|---|---|

| Shipbuilding | Hull structures, decks, bulkheads, side shells |

| Offshore Structures | Oil platforms, subsea pipelines, support columns, jetties |

| Marine Engineering | Cranes, winches, propulsion systems, anchors |

| Heavy Machinery | Excavators, cranes, chassis components, hydraulic arms |

Machining

Heat Treatment

- Preheating: Slowly heat the steel to 600°C (1112°F) to reduce thermal stress.

- Austenitizing: Heat to 900-950°C (1652-1742°F) and hold for sufficient time to ensure full austenitization.

- Quenching: Rapidly cool in water or oil to room temperature.

- Tempering: Reheat to 550-700°C (1022-1292°F) based on desired hardness and toughness. Hold for 1-2 hours.

- Cooling: Allow the steel to air-cool to room temperature.

Surface Finish

- Shot blasting – removes surface impurities and enhances adhesion for coatings.

- Sandblasting – smoothens or roughens the surface for preparation.

- Pickling – removes oxides, rust, and scale through acidic treatment.

- Phosphating – creates a protective layer for corrosion resistance.

- Galvanizing – applies a zinc coating to prevent rust.

- Painting or Coating – adds protective and aesthetic layers.

- Anodizing – enhances corrosion resistance (used mainly for aluminum).

*Customization is available upon request.

Our Service

SteelPRO Group – manufacturer and solution provider for special steel, offering multi-industry application solutions and customised services, 100% quality free, accompanying customers in their growth!

Our Quality Control

- Roundness

- Tolerance

- Microstructure

- Non-Destructive Testing

- Destructive Testing

- Process Control

Service Integration Processing

- Welding

- Metal Fabrication

- CNC Machining

- Lathe

- Forming

QUESTION 1

QUESTION 2

QUESTION 3

QUESTION 4

QUESTION 4

CONTACT

CONTACT

Certifications

Other Products

-

-

SteelPRO Group offers FH550 high-strength structural steel plates for shipbuilding....

-

SteelPRO Group offers DH550 high-strength shipbuilding steel plates in stock....

-

SteelPro Group offers FH36 high-strength steel for shipbuilding. It has...