Hot-dip Galvanized Steel PPGI

Hot-dip Galvanized Steel PPGI

SteelPRO Group is a Hot-dip Galvanized Steel supplier and manufacturer, producing PPGI according to international standards such as ASTM, JIS, EN, GB, etc., suitable for construction, home appliances, automobiles and other fields. We provide PPGI in various grades and forms, including coils, plates, roof panels, etc. to meet diverse needs. The products have excellent corrosion resistance and weather resistance, long life, fire resistance and earthquake resistance. We also provide customization, cutting and processing services, you can customize the color, size, etc., and even spray your logo.

- Standards: ASTM A653, JIS G3302, EN 10346, GB/T 2518, etc.

- Grades: DX51D, DC01, Q195, S220GD, SECC, SGCD, SGHC, FS Type A/B/C, etc.

- Technology: Cold rolling, Hot dip galvanizing, Pre-painted, etc.

- Substrate: Cold rolled steel

- Certification: ISO 9001, CE

Hot-dip Galvanized Steel PPGI

Hot-dip Galvanized Steel PPGI

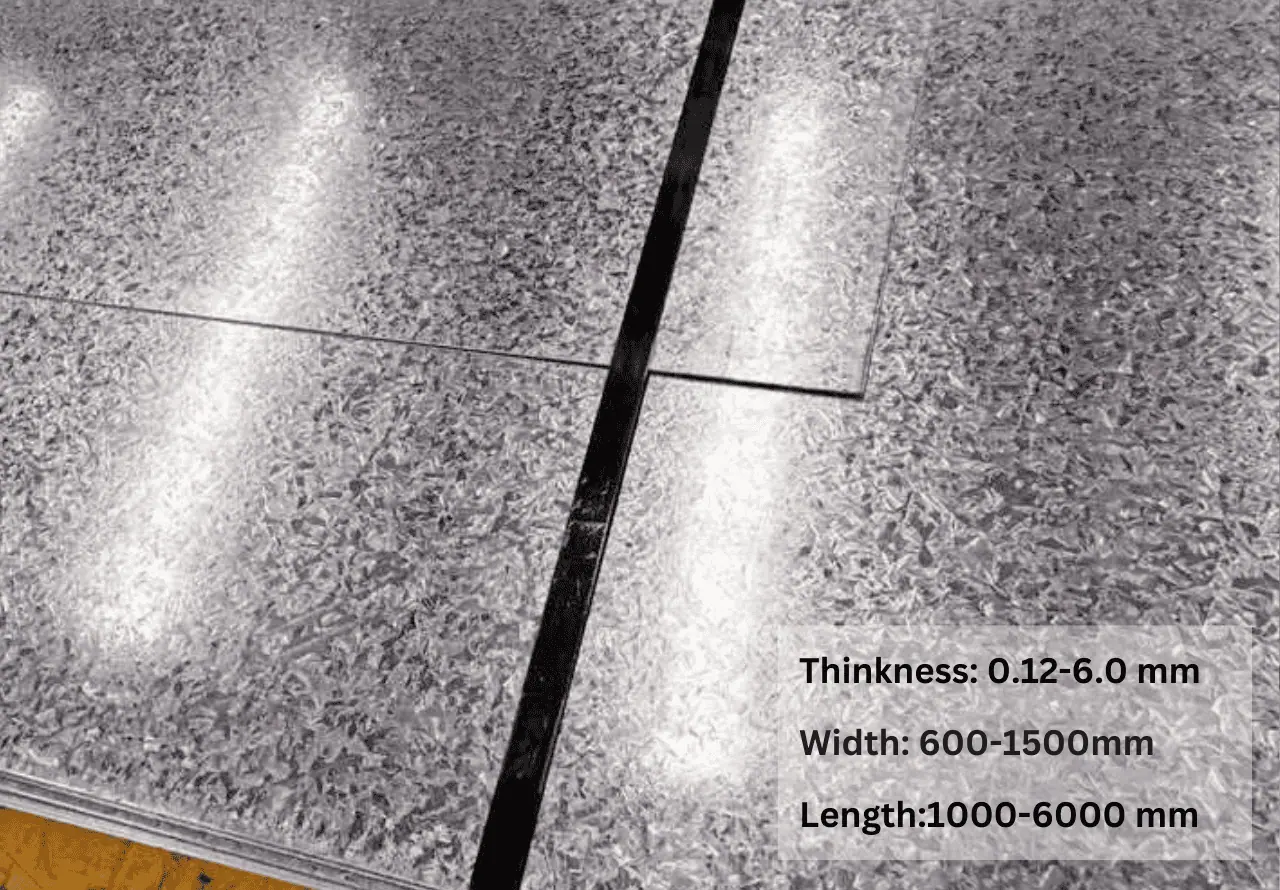

Product Specifications

Product Specifications

| Product Name | Hot dip galvanized steel PPGI |

| Grades | SGCC SGCH SGHC SPCC CGCC

DX51D DX52D DX53D DX54D DX55D DX56D DX57D S220GD S250GD S280GD S320GD S350GD S400GD S500GD S550GD DC01 DC02 DC03 DC04 St02z Q195 Q235 Q215 etc. |

| Thickness | 0.1mm-5mm, Customized |

| Width | 600mm – 2000mm, Customized Regular Width: 914mm, 1000mm, 1219mm, 1220mm, 1250mm |

| Length | Customized |

| Coil Inner | 508mm/610mm, Customized |

| Zinc Layer | 30g – 275g/m² |

| Coating Thickness | Top Coating: 15μm-25μm;

Back Coating: 5μm-20μm. |

| Surface Color | According to required RAL, Wood grain, marble pattern, Customized |

| Coating Material | Polyester (PE), Silicone Polyester (SMP), High Durable Polyester (HDP), Fluoropolymer (PVDF) |

| Painting structure | No coating, single-sided coating, double-sided coating |

| Spangle | Big, regular, mini, and zero spangles |

| Surface Treatment | anti-finger print/skin pass/oiled/dry/chromated/Embossed/Lamination |

| Hardness | Soft (normal), hard, full hard(G300-G550) |

| T Bend | ≧ 3 T |

| Reverse Impact | ≧ 9 J |

| Salt Spray Resistance | ≧ 500 H |

| Anti-MEK Wiping | ≧ 100 Times |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Invoicing | By actual weight |

| Delivery Time | 7-15 days |

| Payment | T/T, L/C, Credit Card |

| Port | Tianjin, Qingdao or according to your requirement |

| Packaging Details | In bundles, in bulk, customized packing |

Chemical Compositions

Chemical Compositions

| Element | Commercial Quality (CQ) | Forming Quality (FQ) | Deep Drawing Quality (DDQ) | Structural Grade |

|---|---|---|---|---|

| Carbon (C) | ≤ 0.15% | ≤ 0.12% | ≤ 0.10% | ≤ 0.20% |

| Manganese (Mn) | ≤ 0.60% | ≤ 0.50% | ≤ 0.45% | ≤ 1.20% |

| Phosphorus (P) | ≤ 0.030% | ≤ 0.025% | ≤ 0.020% | ≤ 0.040% |

| Sulfur (S) | ≤ 0.030% | ≤ 0.025% | ≤ 0.020% | ≤ 0.040% |

| Silicon (Si) | ≤ 0.04% | ≤ 0.03% | ≤ 0.02% | ≤ 0.05% |

| Aluminum (Al) | ≤ 0.02% | ≤ 0.02% | ≤ 0.02% | ≤ 0.04% |

| Zinc (Zn) | ≥ 98.5% | ≥ 98.5% | ≥ 98.5% | ≥ 98.5% |

Mechanical properties

Mechanical properties

| Property | Commercial Quality (CQ) | Forming Quality (FQ) | Deep Drawing Quality (DDQ) | Structural Grade |

|---|---|---|---|---|

| Yield Strength | ≥ 140 MPa | ≥ 120 MPa | ≥ 100 MPa | 240-340 MPa |

| Tensile Strength | 270-370 MPa | 260-350 MPa | 250-340 MPa | 340-440 MPa |

| Elongation | ≥ 20% | ≥ 22% | ≥ 28% | ≥ 18% |

| Hardness (HRB) | ≤ 65 HRB | ≤ 60 HRB | ≤ 55 HRB | ≤ 70 HRB |

| Vickers Hardness (HV) | 90-110 HV | 85-105 HV | 80-100 HV | 110-140 HV |

| Brinell Hardness (HB) | 95-115 HB | 90-110 HB | 85-105 HB | 120-150 HB |

| Rockwell Hardness (HRB) | ≤ 65 HRB | ≤ 60 HRB | ≤ 55 HRB | ≤ 70 HRB |

| Elastic Modulus (GPa) | 200 GPa | 200 GPa | 200 GPa | 200 GPa |

| Bendability | 1T to 1.5T (180°) | 1T to 1.5T (180°) | 0.5T to 1T (180°) | 1.5T to 2T (180°) |

Industries & Applications

Industries & Applications

- Construction and building materials: roof panels, siding, ceilings, wall cladding, interior partitions, prefabricated buildings, modular structures.

- Appliances: refrigerator panels, washing machine casings, air conditioner casings, microwave and oven exteriors, water heater casings.

- Agricultural structures: granaries, warehouse buildings, livestock pens, farm equipment sheds.

- Infrastructure and transportation: highway guardrails, road signs, street light poles, traffic signal poles, electrical towers.

- Furniture and storage solutions: warehouse racks, storage racks, office partitions, cabinet casings.

- Automotive and transportation: body panels, truck bed linings, trailer walls and floors.

- Fencing and security: garden fences, security gates, perimeter fences, balcony railings.

- Other industrial uses: air ducts and ventilation systems, ductwork for HVAC systems, cable trays and conduits.

Other Infomation

Other Infomation

Choosing the right category depends on your specific application needs and the performance requirements of the steel. Let us briefly introduce the characteristics of each category so that you can more clearly judge which one is best for your project.

- Commercial Quality (CQ): Suitable for basic processing and light forming scenarios, such as simple building components and household equipment housings, and economical.

- Forming Quality (FQ): Suitable for applications that require moderate bending and forming, such as automotive interior parts or decorative panels, with good ductility.

- Deep Drawing Quality (DDQ): With excellent ductility, it is suitable for complex forming or deep drawing, such as automotive fuel tanks and electronic equipment housings, and the quality of the finished product is stable.

- Structural Grade: High strength, suitable for load-bearing structural parts and frames, and excels in support and durability.

The following are the common grades corresponding to each category:

Commercial Quality (CQ): SGCC, SPCC, Q195, Q215, Q235, etc.

Forming Quality (FQ): DX51D, DX52D, CGCC, DC01, DC02, etc.

Deep Drawing Quality (DDQ): DX53D, DX54D, DX55D, DX56D, DX57D, DC03, DC04, St02z, etc.

Structural Grade: SGCH, SGHC, S220GD, S250GD, S280GD, S320GD, S350GD, S400GD, S500GD, S550GD, etc.

Our Inventory

Our Inventory

At SteelPRO Group, we are committed to providing customers with high-quality steel solutions with our excellent production capabilities and extensive partnerships. Our production facilities are equipped with multiple advanced production lines to ensure efficient production while meeting strict quality standards. We have established close cooperative relationships with many well-known partners around the world, with an annual production capacity of tens of thousands of tons to quickly respond to market demand. Our team focuses on every manufacturing link to ensure that the products are strictly inspected before leaving the factory, providing customers with long-lasting and reliable steel products.

Main products: Hot dip galvanized steel PPGI, steel pipes, steel plates, steel coils, steel bars, steel strips, stainless steel series, carbon steel series, high-strength steel series, nuclear grade steel, galvanized steel, steel for wind and solar energy, etc.

Packing

Packing

We use professional packaging solutions to ensure that the products are effectively protected during transportation to prevent moisture, scratches and deformation. Each batch of products is strictly packaged and reinforced to meet international transportation standards to ensure that customers receive the products intact. At present, our products are exported to the Middle East, South America, Africa, Southeast Asia and other regions, providing reliable steel solutions for global customers.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

How does the coating of Hot-dip Galvanized Steel PPGI perform in extreme weather conditions?

Our coatings are rigorously tested to maintain good corrosion resistance and weather resistance in extreme climate conditions such as high humidity, high temperature and strong UV environments.

Will the color of Hot-dip Galvanized Steel PPGI fade?

Our products are treated with a high-quality pre-coating process, which is highly weather-resistant, can maintain bright colors and reduce the possibility of fading and cracking even after long-term outdoor use.

Can the thickness and size of Hot-dip Galvanized Steel PPGI be customized according to my needs?

Yes, we offer a variety of thickness and size options, which can be customized according to your specific needs to ensure that the product is perfectly matched to different application scenarios.

Is SteelPRO Group's Hot-dip Galvanized Steel PPGI suitable for repeated processing?

Yes, our products are designed with high durability and flexibility to adapt to multiple processing without easily damaging the coating, suitable for high-demand industrial and assembly applications.

What after-sales services does SteelPRO Group provide?

We provide customers with detailed technical support, product quality assurance and responsive after-sales service to ensure that you have a good experience in use. If there are any problems, our team will assist you in solving them in a timely manner.

Does SteelPRO Group support large-volume orders?

Yes, we have strong production capacity to support large-volume orders and can ensure timely delivery to meet the long-term needs of our customers.

CONTACT

Certificates and Cooperation

Certificates and Cooperation