Hot-dip Galvanized Steel Wire

Hot-dip Galvanized Steel Wire

SteelPRO Group provides high quality hot dip galvanized steel wires that meet international standards such as GB/T 3431 and ASTM A641. Our products are available in a variety of specifications and grades, such as Q195, Q235, and also in round, rectangular, square and other shapes. Our steel wires have excellent corrosion resistance in harsh environments and are widely used in many fields such as building reinforcement, agricultural fencing, power equipment grounding and industrial purposes. In addition, we also provide customization and deep processing services to meet the specific needs of our customers.

- Standards: GB/T 3431, ASTM A641, EN 10264, etc.

- Grades: Q195, Q235, G450, G550, etc.

- Wire gauge: 8-24 gauge, 14 gauge, 16 gauge, 12 gauge, etc.

- Technology: Hot-dip Galvanizing

- Special Use: Landscaping, electrical grounding, special packaging, sports equipment, etc.

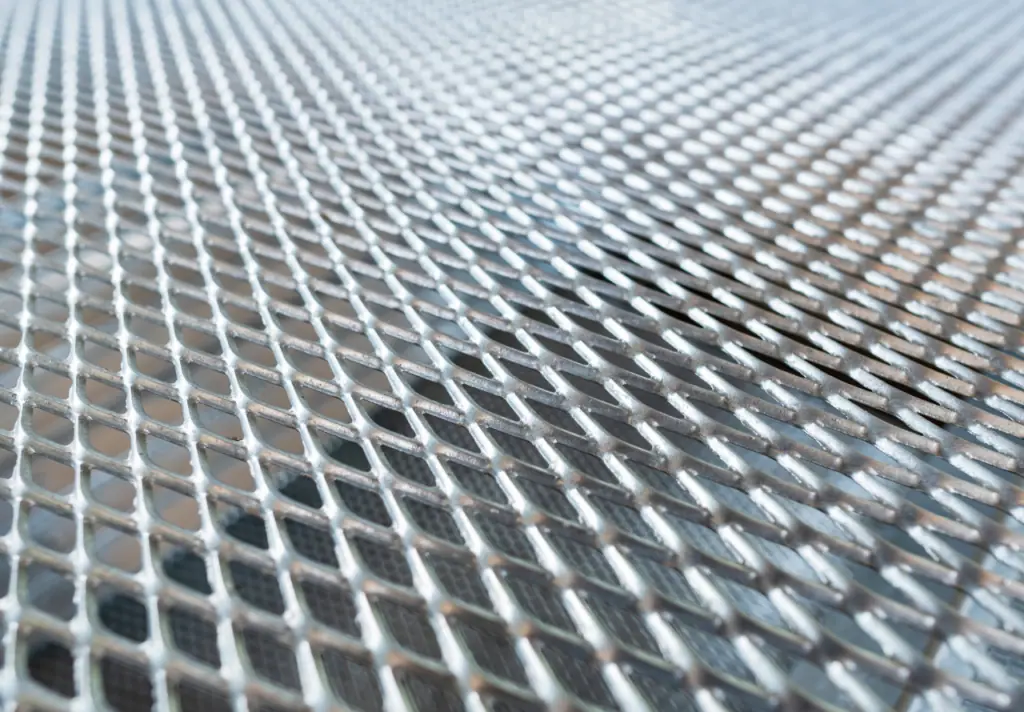

- Form: Coil, Spool, Rope, Mesh

- Certification: ISO 9001, CE

Hot-dip Galvanized Steel Wire

Hot-dip Galvanized Steel Wire

Product Specifications

Product Specifications

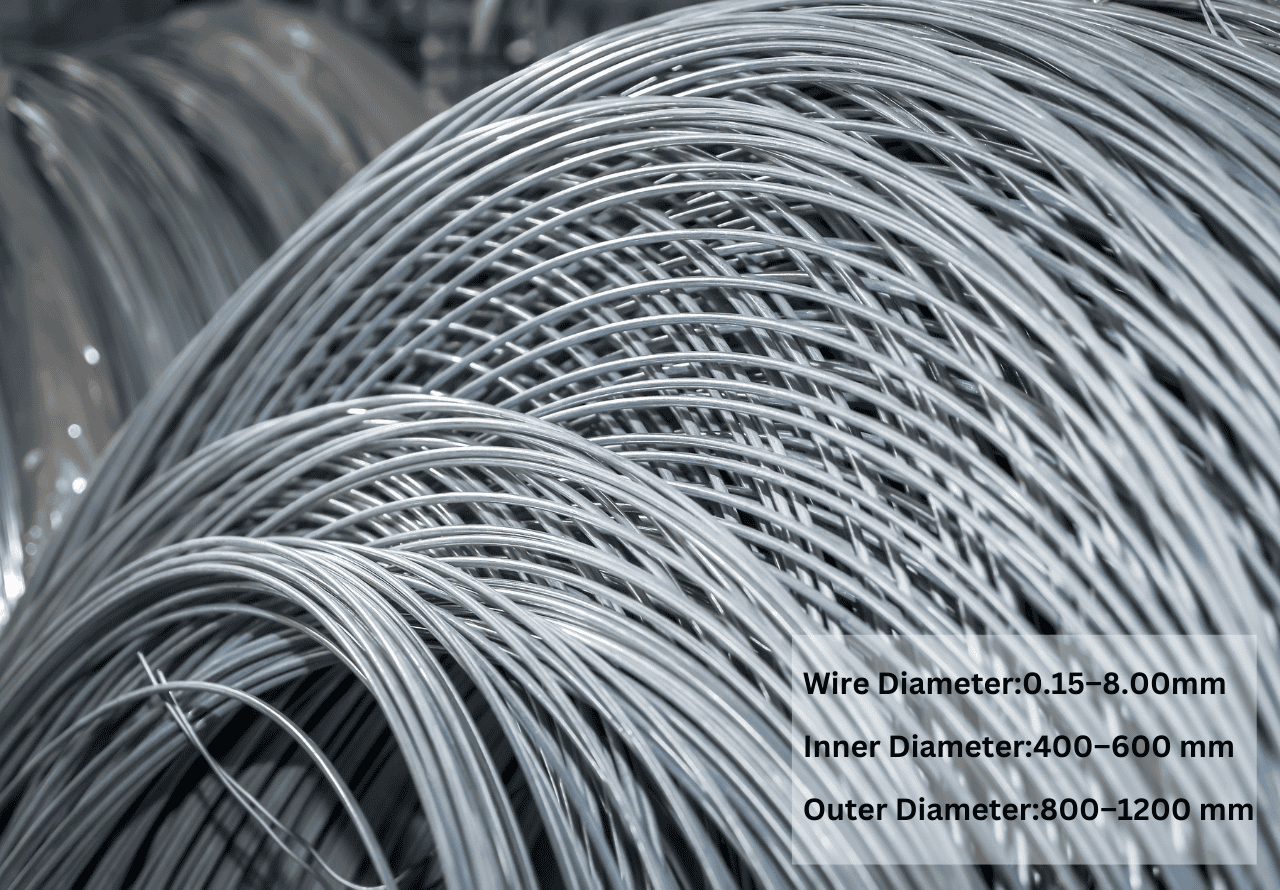

| Product Name | Hot-dip Galvanized Steel Wire | ||

| Wire Diameter | 0.15mm – 8.00mm | ||

| Wire Coil Weight | 20-1200kg | ||

| Wire Coil Length | Varies by coil weight | ||

| Coil Outer Diameter | 800 – 1200 mm | ||

| Coil Inner Diameter | 400 – 600 mm | ||

| Zinc Layer | 20-400g/m², g30, g40, g60, g90, etc. | ||

| Elongation | ≥10% | ||

| Tensile strength | 350–700 MPa | ||

| Load strength | 150 – 1200 N | ||

| Coating Material | Polyester (PE), Silicone Polyester (SMP), High Durable Polyester (HDP), Fluoropolymer (PVDF) | ||

| Surface Treatment | anti-finger print/skin pass/oiled/dry/chromated/Embossed/Lamination | ||

| Tset | Zinc Coating Thickness Test, Adhesion Test, Peel, Bend, Salt Spray Test, Tensile Test, Elongation, etc. | ||

| Tolerance | ±1% | ||

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching | ||

| Invoicing | By actual weight | ||

| Delivery Time | 7-15 days | ||

| Payment | T/T, L/C, Credit Card | ||

| Port | Shanghai, Qingdao or according to your requirement | ||

| Packaging Details | In bundles, in bulk, customized packing | ||

Chemical Compositions

Chemical Compositions

| Element | Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon (Si) |

|---|---|---|---|---|---|

| Content (%) | 0.05 – 0.15 | 0.30 – 0.60 | ≤ 0.04 | ≤ 0.05 | ≤ 0.25 |

Mechanical properties

Mechanical properties

| Property | Typical Values |

|---|---|

| Tensile Strength | 350 – 700 MPa |

| Yield Strength | 200 – 400 MPa |

| Elongation | 10 – 25 % |

| Vickers Hardness | 120 – 220 HV |

| Brinell Hardness | 110 – 210 HB |

| Rockwell Hardness | 60 – 80 HRB |

| Elastic Modulus | 200 – 210 GPa |

Industries & Applications

Industries & Applications

- Construction industry: used for reinforcement and support of buildings, steel bar binding and frame structure.

- Agriculture: making fences, supporting plants, agricultural nets and greenhouse structures to prevent animal intrusion.

- Power and communication: used for cable support and protection, grounding system of power facilities.

- Industrial use: manufacturing parts of machinery and equipment, providing additional strength and corrosion resistance.

- Transportation: used for reinforcement of infrastructure such as bridges, roads and railways.

- Home and gardening: making garden fences, plant supports, lawn borders and home decorations.

- Security protection: making protective nets and safety nets to protect high-altitude operations and construction sites.

- Special use: used in specific areas such as art installations and military facilities to provide strength and flexibility.

Other Infomation

Other Infomation

In terms of surface treatment and coating thickness of hot-dip galvanized steel wire, we provide a variety of options to better meet customers’ usage needs and special requirements in different environments.

Surface treatment options

- Glossy: The surface is smooth and bright, suitable for applications with high appearance requirements.

- Matt surface: Low reflectivity, more suitable for industrial or outdoor low reflectivity requirements.

- Coating treatment: Add a special coating on the galvanized layer to enhance corrosion resistance, suitable for marine or acid-base environments.

- Phosphating treatment: Improve wear resistance and adhesion, suitable for industrial applications that require further painting or spraying.

- Oil film protection: Provides short-term corrosion protection, suitable for protection during storage or transportation.

- Passivation treatment: Prevents the formation of “white rust” and extends the service life of outdoor applications.

Coating thickness options

- Standard thickness: 40-60 g/m², suitable for indoor and low humidity environments.

- Medium thickness: 70-100 g/m², suitable for general outdoor environments, providing better corrosion protection.

- Thick coating: 120-200 g/m², suitable for high humidity, marine environment, with the strongest anti-corrosion performance.

Our Inventory

Our Inventory

Galvanized steel manufacturer SteelPRO Group has excellent production capabilities and a strong network of partners. We have established long-term cooperative relationships with many well-known partners to ensure a stable supply of raw materials while strictly adhering to high standards of quality control. Our modern production base has multiple advanced production lines with sufficient capacity to meet the needs of large-scale and customized orders. Whether it is production speed or quality assurance, we are committed to exceeding customer expectations and providing reliable support for every batch of products.

Main products: Hot-dip galvanized steel wire, steel pipes, steel plates, steel coils, steel bars, steel strips, stainless steel series, carbon steel series, high-strength steel series, nuclear grade steel, galvanized steel, steel for wind and solar energy, etc.

Packing

Packing

Our products are exported to the Middle East, South America, Africa, Southeast Asia and other regions. We provide safe and reliable packaging and logistics services to customers worldwide to ensure that the goods are delivered on time and arrive in good condition. Our products are professionally packaged to ensure safety and quality during transportation. Each batch of hot-dip galvanized steel wire uses moisture-proof and protective film and reinforced outer packaging to avoid damage caused by handling or climatic conditions. We also provide a variety of packaging solutions that can be customized according to customer needs to ensure that the products arrive intact, easy to store and use.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

How long can your hot-dip galvanized steel wire last?

Our hot-dip galvanized steel wire can last more than 10 years under normal conditions and maintain good corrosion resistance in outdoor or humid environments. The specific life span will vary depending on the conditions of use.

Can the length and packaging of the steel wire be customized according to the project requirements?

Yes, we can customize the length and packaging of the steel wire according to your project requirements for easier transportation and use. Please let us know your specific requirements and our team will provide a suitable customized solution.

How to get a sample or quote for the product?

You can get samples and quotes through our official website or contact sales directly. We will provide detailed product information and prices based on your specific needs to support you in making the best choice.

What specifications are available for hot-dip galvanized steel wire?

We offer a variety of specifications of hot-dip galvanized steel wire, including different diameters and strength grades to meet various application requirements. You can contact our sales team to help choose the model and specifications suitable for your project.

Will the zinc coating of the steel wire fall off over time?

We use a strict hot-dip galvanizing process, and the zinc layer has a uniform thickness and strong adhesion, which can effectively delay corrosion. As long as it is used under appropriate conditions, the coating can last for a long time and is not easy to fall off or lose its protective properties.

Can I visit your factory?

Yes, we welcome customers to make an appointment to visit the factory and learn about our production process and quality control in person. Please contact our team in advance to arrange a suitable visit time.

CONTACT

Certificates and Cooperation

Certificates and Cooperation