A841 | Alloy Pressure Vessel Steel

A841 | Alloy Pressure Vessel Steel

A841 is an alloy steel pressure vessel and boilers known for its high strength and toughness. “A” designates it as a ferrous material, and “841” refers to the ASTM standard for thermomechanically processed plates. It’s also called TMCP steel, offering excellent weldability, impact toughness, and resistance to fracture. Used in high-pressure equipment and tanks. Similar grades include P500Q, P690Q.

Description

What is A841?

A841 is a steel alloy with 1.25% chromium and 0.5% molybdenum, designed for pressure vessels. It undergoes thermomechanical processing (TMCP) to improve toughness and strength. A841 offers excellent weldability, impact resistance, and fracture toughness, ideal for high-pressure use in oil, gas, chemical, and power industries. It comes in seven grades: A, B, C, D, E, F, G, with classifications like Class 1 and Class 2, based on tensile strength and heat treatment, as well as other classifications.Why Choose A841 Alloy Pressure Vessel Steel?

For high-pressure environments, A841 Pressure Vessel Steel is a top choice. We recommend A841 for its toughness, weldability, and impact resistance. Its thermomechanical processing ensures excellent performance in demanding conditions, ideal for industries like oil, gas, and power. Choosing A841 means long-term safety and reliability. A841 stands out from other steels by offering consistent performance under stress and fewer welding issues. Its excellent fracture toughness and adaptability make it perfect for critical applications. If you need alternatives, we also offer A387 and A516, which provide similar high-pressure capabilities to suit your project.Product Specification

| Category | Details |

| Quality Standard | ASTM A841/A841M |

| Certifications | ISO 9001, CE, BPVC, EN 10028, ISO 14001, ISO 15156 |

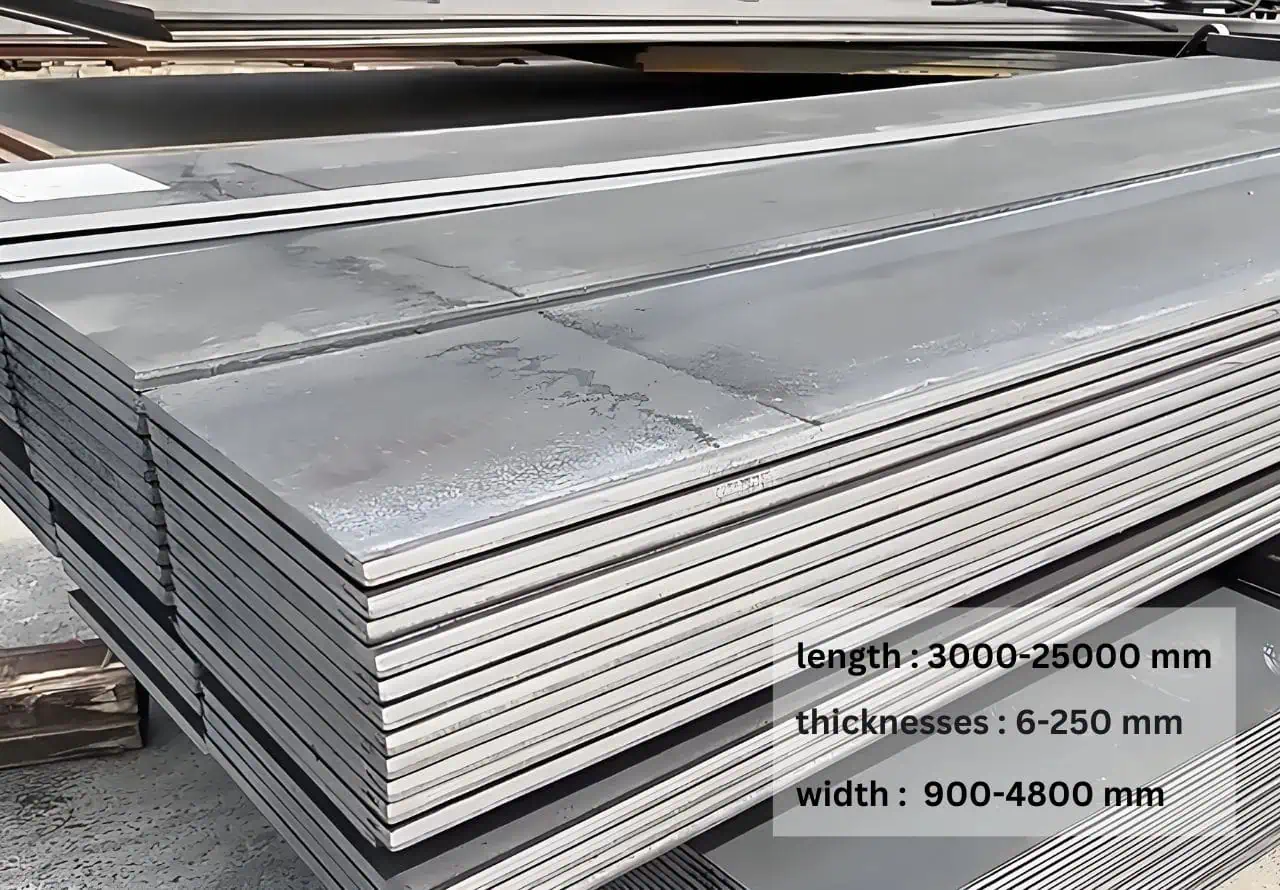

| Thickness | 8-100mm |

| Width | 900-4800mm |

| Length | 3000-25000mm |

| Weight | Depends on length and width |

| Outer diameter (OD) | Pipes: 20 mm to 610 mm, Bars: 10 mm to 400 mm |

| Inner diameter (ID) | Pipes: 15 mm to 600 mm |

| Tolerances | Thickness: ±0.3mm to ±1.2mm, Width: ±3mm to ±10mm, Length: ±5mm to ±15mm |

| Technology | Hot Rolling, TMCP |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Shapes | Pressure Vessel Steel Plate, Pressure Vessel Steel Sheet, Pipes, Profiles |

| MOQ (Minimum Order Quantity) | 5 tons (according to the actual tonnage) |

| Lead Time | Typically 7-20 days |

| Price Terms & Payment | Based on customer requirements, T/T, L/C |

| Ports | Qingdao, Lianyungang, Dalian |

| Export Countries | Southeast Asia, Central Asia, Europe, Russia, South America, Middle East, etc. |

| Shipping Method | Offers Sea, Air and Customized Shipping |

Chemical Compositions

| Element | Grade A (Class 1) | Grade B (Class 1) | Grade C (Class 1) | Grade D (Class 3) | Grade E (Class 4) | Grade F (Class 6) | Grade G (Class 10) |

|---|---|---|---|---|---|---|---|

| Carbon, C | 0.2 max | 0.15 max | 0.1 max | 0.09 max | 0.07 max | 0.1 max | 0.13 max |

| Silicon, Si | 0.15 – 0.5 | 0.15 – 0.5 | 0.15 – 0.5 | 0.05 – 0.25 | 0.05 – 0.3 | 0.1 – 0.45 | 0.04 – 0.15 |

| Manganese, Mn | 0.7 – 1.35 | 0.7 – 1.35 | 0.7 – 1.6 | 1 – 2 | 0.7 – 1.6 | 1.1 – 1.7 | 0.6 – 1.2 |

| Phosphorus, P | 0.03 max | 0.03 max | 0.03 max | 0.01 max | 0.015 max | 0.02 max | 0.015 max |

| Sulfur, S | 0.03 max | 0.025 max | 0.015 max | 0.005 max | 0.005 max | 0.008 max | 0.015 max |

| Chromium, Cr | 0.25 max | 0.25 max | 0.25 max | 0.3 max | 0.3 max | 0.3 max | 1 max |

| Nickel, Ni | 0.25 max | 0.6 max | 0.25 max | 1 – 5 | 0.6 max | 0.85 max | 6 – 7.5 |

| Copper, Cu | 0.35 max | 0.35 max | 0.35 max | 0.5 max | 0.35 max | 0.4 max | 0.35 max |

| Molybdenum, Mo | 0.08 max | 0.3 max | 0.08 max | 0.4 max | 0.3 max | 0.5 max | 0.3 max |

| Vanadium, V | 0.06 max | 0.06 max | 0.06 max | 0.02 max | 0.06 max | 0.09 max | 0.02 max |

| Niobium, Nb | 0.03 max | 0.03 max | 0.06 max | 0.05 max | 0.08 max | 0.1 max | 0.05 max |

| Titanium, Ti | – | – | 0.02 max | 0.03 max | – | – | 0.02 max |

| Boron, B | – | – | – | 0.0005 – 0.002 | 0.0007 max | 0.0007 max | 0.0005 – 0.002 |

| Aluminum, Al | Al≥0.02 or Als≥0.015 | Al≥0.02 or Als≥0.015 | Al≥0.02 or Als≥0.015 | 0.02 min | Al≥0.02 or Als≥0.015 | Al≥0.02 or Als≥0.015 | 0.008 min |

Mechanical Properties

| Property | Grade A (Class 1) | Grade B (Class 1) | Grade C (Class 1) | Grade D (Class 3) | Grade E (Class 4) | Grade F (Class 6) | Grade G (Class 10) |

|---|---|---|---|---|---|---|---|

| Tensile Strength | 585 – 760 MPa | 85 – 110 ksi | 585 – 760 MPa | 85 – 110 ksi | 620 – 790 MPa | 90 – 115 ksi | 690 – 830 MPa | 100 – 120 ksi | 620 – 790 MPa | 90 – 115 ksi | 620 – 760 MPa | 90 – 110 ksi | 690 – 930 MPa | 100 – 135 ksi |

| Yield Strength | 485 MPa | 70 ksi | 485 MPa | 70 ksi | 515 MPa | 75 ksi | 585 MPa | 85 ksi | 515 MPa | 75 ksi | 515 MPa | 75 ksi | 620 MPa | 90 ksi |

| Brinell Hardness (HB) | 170 – 220 HB | 170 – 220 HB | 180 – 230 HB | 200 – 250 HB | 180 – 230 HB | 180 – 230 HB | 200 – 260 HB |

| Rockwell Hardness (HRC) | 82 – 90 HRB | 82 – 90 HRB | 83 – 92 HRB | 87 – 95 HRB | 83 – 92 HRB | 83 – 92 HRB | 87 – 96 HRB |

| Vickers Hardness (HV) | 170 – 220 HV | 170 – 220 HV | 180 – 230 HV | 200 – 250 HV | 180 – 230 HV | 180 – 230 HV | 200 – 260 HV |

| Elongation (% in 50mm) | 18% | 18% | 16% | 15% | 16% | 16% | 14% |

| Elastic Modulus | 200 GPa | 29,000 ksi | 200 GPa | 29,000 ksi | 200 GPa | 29,000 ksi | 200 GPa | 29,000 ksi | 200 GPa | 29,000 ksi | 200 GPa | 29,000 ksi | 200 GPa | 29,000 ksi |

Data After Normalizing Processing

| Property | Grade A (Class 1) | Grade B (Class 1) | Grade C (Class 1) | Grade D (Class 3) | Grade E (Class 4) | Grade F (Class 6) | Grade G (Class 10) |

|---|---|---|---|---|---|---|---|

| Tensile Strength | 690 – 830 MPa | 100 – 120 ksi | 690 – 830 MPa | 100 – 120 ksi | 760 – 900 MPa | 110 – 130 ksi | 830 – 930 MPa | 120 – 135 ksi | 760 – 900 MPa | 110 – 130 ksi | 690 – 860 MPa | 100 – 125 ksi | 830 – 960 MPa | 120 – 140 ksi |

| Yield Strength | 585 MPa | 85 ksi | 585 MPa | 85 ksi | 620 MPa | 90 ksi | 690 MPa | 100 ksi | 620 MPa | 90 ksi | 620 MPa | 90 ksi | 690 MPa | 100 ksi |

| Brinell Hardness (HB) | 200 – 250 HB | 200 – 250 HB | 210 – 270 HB | 230 – 280 HB | 210 – 270 HB | 200 – 260 HB | 230 – 300 HB |

| Rockwell Hardness (HRC) | 87 – 95 HRB | 87 – 95 HRB | 88 – 96 HRB | 90 – 98 HRB | 88 – 96 HRB | 87 – 96 HRB | 90 – 99 HRB |

| Vickers Hardness (HV) | 200 – 250 HV | 200 – 250 HV | 210 – 270 HV | 230 – 280 HV | 210 – 270 HV | 200 – 260 HV | 230 – 300 HV |

| Elongation (% in 50mm) | 15% | 15% | 14% | 13% | 14% | 14% | 12% |

| Elastic Modulus | 200 GPa | 29,000 ksi | 200 GPa | 29,000 ksi | 200 GPa | 29,000 ksi | 200 GPa | 29,000 ksi | 200 GPa | 29,000 ksi | 200 GPa | 29,000 ksi | 200 GPa | 29,000 ksi |

Industries & Applications

| Industries | Products |

|---|---|

| Pressure Vessels | Chemical reactors, Gas storage tanks, Boiler drums, Heat exchangers, LPG storage tanks |

| Shipbuilding | Hull structures, Bulkheads, Deck structures, Offshore platforms, Submarine hulls |

| Oil and Gas | Storage tanks, Oil platforms, Pipeline systems, Drilling equipment, Pressure valves |

| Nuclear Power Plants | Reactor pressure vessels, Containment vessels, Steam generators, Nuclear waste containers, Heat exchangers |

| Petrochemical Industry | Process vessels, Distillation towers, Heat exchangers, Chemical storage tanks, Gas scrubbers |

| Construction | Structural beams, Steel bridges, Heavy-duty columns, Foundation supports, Offshore wind structures |

| Mining Equipment | Excavator arms, Mining truck bodies, Crushers, Shovels, Loaders |

| Aerospace | Aircraft fuselage, Spacecraft structural parts, Launch vehicle tanks, Pressure tanks, Engine components |

| Military | Armored vehicles, Missile silos, Submarine pressure hulls, Tank turrets, Ammunition storage containers |

Packing

Here are four key advantages of SteelPRO Group in packing A841 steel:

- Tailored Packaging: We customize packaging for A841, ensuring proper fit and protection for different sizes and thicknesses.

- Corrosion Protection: We use moisture-resistant wraps and corrosion inhibitors to safeguard A841 steel from damage.

- Reinforced Strapping: Secure strapping methods keep A841 stable during transport, preventing movement and damage.

- Compliance with Standards: We meet international packaging standards, ensuring safe and compliant transport for A841 steel.

SteelPRO Group ensures reliable, high-quality packaging for A841 steel.

Machining

A841 Heat Treatment Product Options

We offer the following heat-treated A841 alloy pressure vessel steels:

- Quenched and Tempered A841 Steel: Processed at 900-1150°C, providing high strength and toughness for demanding applications.

- Normalized A841 Steel: Treated at 870-950°C, offering enhanced ductility and good weldability.

- TMCP A841 Steel: Improved strength and weldability through thermo-mechanical processing.

- Stress-Relieved A841 Steel: Heated at 540-600°C to reduce residual stresses after welding or forming.

- Custom Options: We also supply as-rolled or custom-specified A841 steel to meet your needs.

Our A841 steel ensures optimal mechanical properties for various applications.

A841 Surface Finish

We offer the following surface treatments for A841 steel:

- Shot Blasting: Removes rust, scale, and contaminants, providing a clean surface for further processing.

- Pickling: Removes oxides and impurities, improving corrosion resistance and preparing the surface for coating.

- Galvanizing: Applies a protective zinc coating, preventing corrosion and extending the lifespan of the steel.

- Painting: Adds a protective layer to prevent corrosion and enhance aesthetics, available in a variety of coatings.

- Anti-Corrosion Coating: Provides a specialized layer that protects against harsh environmental conditions and chemical exposure.

Custom surface treatment requirements can be accommodated upon request.

A841 Pressure Vessel Steel Supplier

As a trusted supplier of A841 Alloy Pressure Vessel Steel, we provide industry-leading service and expertise across multiple aspects:

Competitive Pricing: We offer highly competitive prices without compromising on quality, ensuring value for your investment.

Timely Delivery: Our efficient production and logistics ensure fast lead times, keeping your projects on schedule.

Comprehensive Product Range: We supply a full range of A841 grades to meet diverse application needs, with various thicknesses and sizes available.

Strict Quality Assurance and Certifications: Every batch of A841 steel undergoes stringent quality testing, and we provide certifications in accordance with international standards like EN 10204 3.1/3.2.

Custom Solutions: We deliver tailor-made solutions based on your project requirements, including customized sizes, forms, and surface treatments.

Safe Packaging and Efficient Logistics: We ensure secure, damage-free packaging for all A841 steel products and provide reliable, transparent logistics to guarantee smooth delivery.

With us, you get a professional, comprehensive solution for all your A841 Alloy Pressure Vessel Steel needs.

Our Service

SteelPRO Group – manufacturer and solution provider for special steel, offering multi-industry application solutions and customised services, 100% quality free, accompanying customers in their growth!

Our Quality Control

- Roundness

- Tolerance

- Microstructure

- Non-Destructive Testing

- Destructive Testing

- Process Control

Service Integration Processing

- Welding

- Metal Fabrication

- CNC Machining

- Lathe

- Forming

What Is The Difference Between Class 1 And Class 2 For A841 Steel?

Class 1 and Class 2 differ mainly in heat treatment and mechanical properties, with Class 2 offering higher strength for more demanding applications.

Can A841 Alloy Be Used For High-Pressure Environments?

Yes, A841 is designed for high-pressure environments, commonly used in pressure vessels and storage tanks.

Does A841 Steel Offer Good Weldability?

Yes, A841 steel has good weldability, particularly after heat treatments like normalizing or tempering.

Do You Offer Support With Technical Specifications And Drawings?

Yes, we provide full support with technical specifications, including customized solutions based on your project’s drawings and needs.

Can You Accommodate Urgent Requests?

Yes, we work closely with clients to handle urgent requests and expedite orders when necessary, depending on stock availability and processing requirements.

What Kind Of Testing Is Done Before Shipment?

We conduct thorough testing, including mechanical and chemical property verification, to ensure that all products meet industry standards before shipment.

CONTACT

CONTACT

Certifications

Other Products

-

-

SteelPRO Group offers FH550 high-strength structural steel plates for shipbuilding....

-

SteelPRO Group offers DH550 high-strength shipbuilding steel plates in stock....

-

SteelPro Group offers FH36 high-strength steel for shipbuilding. It has...