S355 | High Strength Structural Steel

S355 | High Strength Structural Steel

S355 is a non-alloy structural steel under EN 10025 with a minimum yield strength of 355 MPa. The name “S” stands for structural steel, and “355” indicates the yield strength in MPa. It is also known by equivalent grades such as Q355B (GB) and A572 Grade 50 (USA). S355 features good weldability, high strength, and moderate toughness, making it suitable for construction, bridges, and heavy machinery.

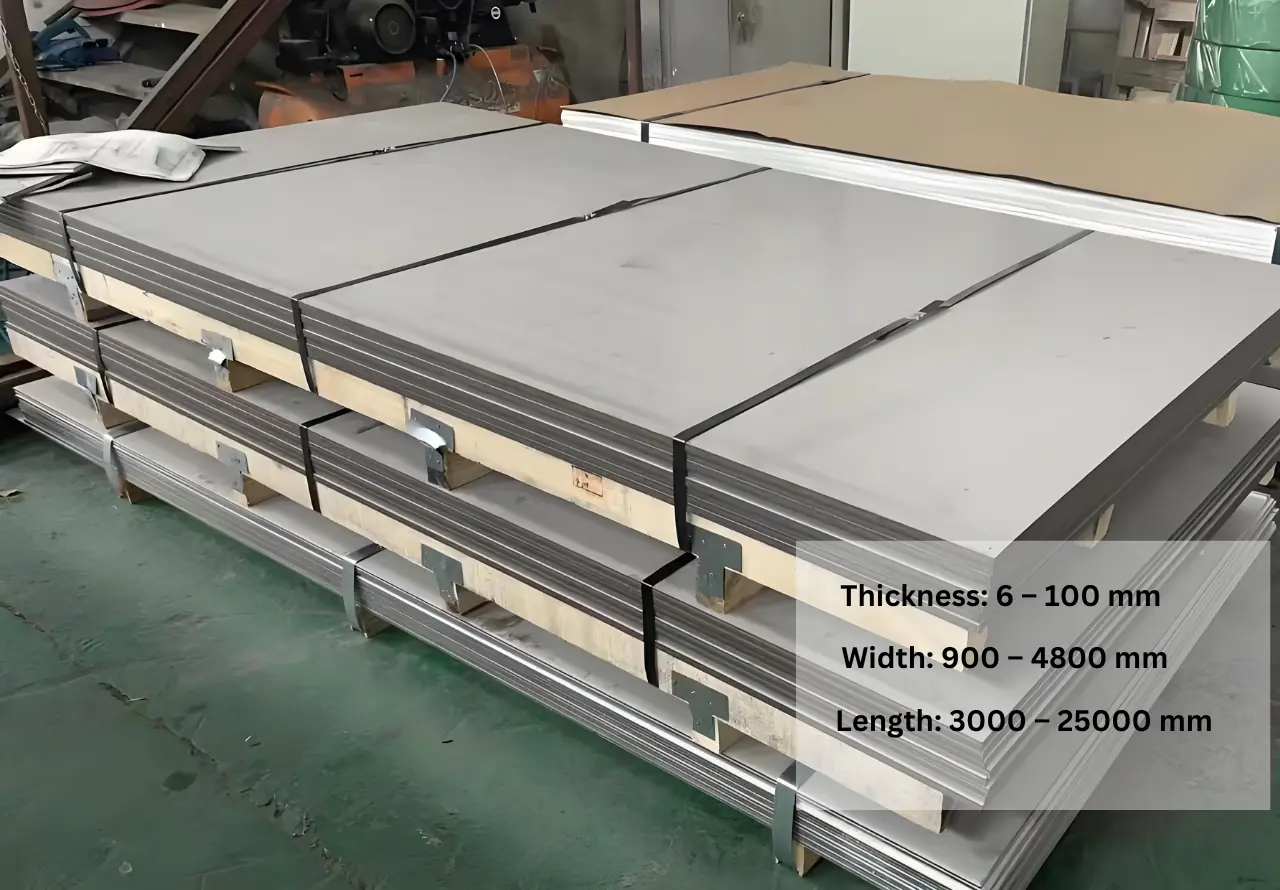

We can supply the S355 sub-series from 6 to 300 mm thickness, 900~4800 mm width, and 3000~25000 mm length according to standards EN 10025-2, 3, and 4, respectively.

Description

What is S355?

S355 is a structural steel made of about 98% iron with small amounts of carbon, manganese, silicon, and phosphorus. It is typically supplied in solid plates, bars, or sections and processed through hot rolling. S355 features high strength, good weldability, and moderate toughness, making it ideal for construction, bridges, wind turbines, and heavy machinery. It has several subgrades based on impact energy: S355JR (27J at +20°C), S355J0 (27J at 0°C), S355J2 (27J at -20°C), and S355K2 (40J at -20°C). Its equivalents include Q355B (China) and A572 Grade 50 (USA).Characteristics of S355 Steel

S355 steel offers excellent impact toughness and good weather resistance, making it reliable in harsh environments. It comes in multiple quality grades (JR, J0, J2, K2, N, M) to suit various temperature conditions and applications. The material provides high strength, good weldability, and flexibility for structural uses. S355 is widely used in construction, bridges, offshore structures, wind turbines, and heavy equipment. For applications needing higher strength or enhanced corrosion resistance, alternatives like S460, Corten Steel, or HSLA (ASTM A588, A572) Steel may be more suitable.Chemical Compositions

| Element | S355JR / J0 | S355J2 | S355K2 | S355N | S355M |

|---|---|---|---|---|---|

| Carbon, C | ≤ 0.24% | ≤ 0.22% | ≤ 0.22% | ≤ 0.18% | ≤ 0.16% |

| Silicon, Si | ≤ 0.60% | ≤ 0.60% | ≤ 0.60% | ≤ 0.50% | ≤ 0.50% |

| Manganese, Mn | ≤ 1.60% | ≤ 1.60% | ≤ 1.60% | 1.00–1.70% | 1.10–1.70% |

| Phosphorus, P | ≤ 0.045% | ≤ 0.035% | ≤ 0.035% | ≤ 0.025% | ≤ 0.025% |

| Sulfur, S | ≤ 0.045% | ≤ 0.035% | ≤ 0.035% | ≤ 0.020% | ≤ 0.020% |

| Nitrogen, N | ≤ 0.012% | ≤ 0.012% | ≤ 0.012% | ≤ 0.012% | ≤ 0.012% |

| Copper, Cu | ≤ 0.55% | ≤ 0.55% | ≤ 0.55% | ≤ 0.55% | ≤ 0.55% |

| Aluminum, Al | ≥ 0.02% | ≥ 0.02% | ≥ 0.02% | ≥ 0.02% | ≥ 0.02% |

| Iron, Fe | Balance | Balance | Balance | Balance | Balance |

Physical Properties

| Property | S355JR / J0 | S355J2 | S355K2 | S355N | S355M |

|---|---|---|---|---|---|

| Density | 7.85 g/cm³ / 0.284 lb/in³ | 7.85 g/cm³ / 0.284 lb/in³ | 7.85 g/cm³ / 0.284 lb/in³ | 7.85 g/cm³ / 0.284 lb/in³ | 7.85 g/cm³ / 0.284 lb/in³ |

| Melting Point | 1425–1540 °C / 2597–2800 °F | 1425–1540 °C / 2597–2800 °F | 1425–1540 °C / 2597–2800 °F | 1425–1540 °C / 2597–2800 °F | 1425–1540 °C / 2597–2800 °F |

| Boiling Point | ~3000 °C / ~5432 °F | ~3000 °C / ~5432 °F | ~3000 °C / ~5432 °F | ~3000 °C / ~5432 °F | ~3000 °C / ~5432 °F |

| Thermal Conductivity | 50 W/m·K / 289 BTU/(hr·ft·°F) | 49 W/m·K / 283 BTU/(hr·ft·°F) | 49 W/m·K / 283 BTU/(hr·ft·°F) | 47 W/m·K / 272 BTU/(hr·ft·°F) | 46 W/m·K / 265 BTU/(hr·ft·°F) |

| Electrical Conductivity | 6.99 MS/m / 6.99 MS/m | 6.80 MS/m / 6.80 MS/m | 6.80 MS/m / 6.80 MS/m | 6.50 MS/m / 6.50 MS/m | 6.40 MS/m / 6.40 MS/m |

| Specific Heat Capacity | 480 J/(kg·K) / 0.114 BTU/(lb·°F) | 480 J/(kg·K) / 0.114 BTU/(lb·°F) | 480 J/(kg·K) / 0.114 BTU/(lb·°F) | 490 J/(kg·K) / 0.117 BTU/(lb·°F) | 490 J/(kg·K) / 0.117 BTU/(lb·°F) |

| Thermal Expansion Coefficient | 12 × 10⁻⁶ /K / 6.7 × 10⁻⁶ /°F | 11.9 × 10⁻⁶ /K / 6.6 × 10⁻⁶ /°F | 11.9 × 10⁻⁶ /K / 6.6 × 10⁻⁶ /°F | 11.7 × 10⁻⁶ /K / 6.5 × 10⁻⁶ /°F | 11.5 × 10⁻⁶ /K / 6.4 × 10⁻⁶ /°F |

| Electrical Resistivity | 142 nΩ·m / 142 nΩ·m | 145 nΩ·m / 145 nΩ·m | 145 nΩ·m / 145 nΩ·m | 150 nΩ·m / 150 nΩ·m | 152 nΩ·m / 152 nΩ·m |

Mechanical Properties

| Property | S355JR / J0 | S355J2 | S355K2 | S355N | S355M |

|---|---|---|---|---|---|

| Tensile Strength | 470–630 MPa / 68,170–91,370 psi | 490–630 MPa / 71,100–91,370 psi | 490–630 MPa / 71,100–91,370 psi | 510–680 MPa / 73,950–98,610 psi | 510–680 MPa / 73,950–98,610 psi |

| Yield Strength | 355 MPa / 51,490 psi | 355 MPa / 51,490 psi | 355 MPa / 51,490 psi | 420 MPa / 60,900 psi | 420 MPa / 60,900 psi |

| Elastic Modulus | 210 GPa / 30,458 ksi | 210 GPa / 30,458 ksi | 210 GPa / 30,458 ksi | 210 GPa / 30,458 ksi | 210 GPa / 30,458 ksi |

| Poisson’s Ratio | 0.27–0.30 | 0.27–0.30 | 0.27–0.30 | 0.27–0.30 | 0.27–0.30 |

| Brinell Hardness | 146–187 HB | 150–190 HB | 150–190 HB | 180–220 HB | 180–220 HB |

| Rockwell Hardness | 84 HRB (approx.) | 85–90 HRB (approx.) | 85–90 HRB (approx.) | 90–95 HRB (approx.) | 90–95 HRB (approx.) |

| Vickers Hardness | 150–190 HV | 160–200 HV | 160–200 HV | 200–240 HV | 200–240 HV |

| Elongation | 18–22% | 16–20% | 16–20% | 12–16% | 12–16% |

Data After QT(Quenching and Tempering) Processing

| Property | S355JR / J0 (QT) | S355J2 (QT) | S355K2 (QT) | S355N (QT) | S355M (QT) |

|---|---|---|---|---|---|

| Tensile Strength | 750–950 MPa / 108,800–137,800 psi | 800–1000 MPa / 116,000–145,000 psi | 800–1000 MPa / 116,000–145,000 psi | 850–1100 MPa / 123,250–159,500 psi | 850–1100 MPa / 123,250–159,500 psi |

| Yield Strength | 500–650 MPa / 72,500–94,300 psi | 550–700 MPa / 79,800–101,500 psi | 550–700 MPa / 79,800–101,500 psi | 600–750 MPa / 87,000–108,800 psi | 600–750 MPa / 87,000–108,800 psi |

| Elastic Modulus | 210 GPa / 30,458 ksi | 210 GPa / 30,458 ksi | 210 GPa / 30,458 ksi | 210 GPa / 30,458 ksi | 210 GPa / 30,458 ksi |

| Poisson’s Ratio | 0.27–0.30 | 0.27–0.30 | 0.27–0.30 | 0.27–0.30 | 0.27–0.30 |

| Brinell Hardness | 230–300 HB | 240–320 HB | 240–320 HB | 260–340 HB | 260–340 HB |

| Rockwell Hardness | 95–100 HRB (approx.) | 96–102 HRB (approx.) | 96–102 HRB (approx.) | 98–104 HRB (approx.) | 98–104 HRB (approx.) |

| Vickers Hardness | 240–300 HV | 250–320 HV | 250–320 HV | 280–340 HV | 280–340 HV |

| Elongation | 10–14% | 8–12% | 8–12% | 6–10% | 6–10% |

Industries & Applications

| Industries | Products |

|---|---|

| Construction | Beams, Columns, Trusses, Frames, Railings |

| Bridge Engineering | Bridge Girders, Decks, Supports, Bearings, Guardrails |

| Offshore Structures | Oil Rigs, Wind Turbine Foundations, Platforms, Piping Systems, Anchors |

| Heavy Machinery | Cranes, Excavators, Bulldozers, Forklifts, Loaders |

| Energy | Wind Towers, Solar Panel Frames, Hydropower Structures, Pipeline Supports, Transformers |

| Automotive | Chassis, Suspension Arms, Truck Frames, Axle Housings, Body Panels |

| Rail Infrastructure | Rails, Sleepers, Platforms, Signal Structures, Overhead Line Supports |

| Shipbuilding | Hulls, Deck Plates, Bulkheads, Masts, Containers |

| Mining Equipment | Drilling Rigs, Conveyor Systems, Crushers, Shovels, Dump Trucks |

Machining

S355 Steel Heat Treatment

- Normalizing:

- Heat to 850–900°C (1560–1650°F), hold until uniform temperature.

- Effect: Refines grain structure, improves toughness, and prepares the steel for machining or further heat treatment.

- Annealing:

- Heat to 680–750°C (1256–1382°F), then cool slowly in the furnace.

- Effect: Reduces hardness, relieves internal stress, and enhances ductility.

- Quenching:

- Heat to 860–920°C (1580–1690°F), then rapidly cool in water or oil.

- Effect: Increases hardness and strength but reduces toughness.

- Tempering:

- After quenching, reheat to 500–680°C (932–1256°F), followed by air cooling.

- Effect: Restores toughness, reduces brittleness, and adjusts hardness.

- Stress Relieving:

- Heat to 550–650°C (1022–1202°F), hold for 1–2 hours, and cool in air.

- Effect: Minimizes residual stresses from welding or machining without significant changes in hardness or strength.

S355 Surface Finish

- Shot Blasting: Improves surface cleanliness and adhesion for coatings.

- Pickling: Removes rust, scale, and impurities, enhancing corrosion resistance.

- Galvanizing: Adds a zinc layer to protect against corrosion.

- Powder Coating: Provides a durable, decorative, and corrosion-resistant finish.

- Painting: Adds color, protection, and environmental resistance.

- Anodizing (for special alloys): Increases corrosion resistance and wear properties.

- Polishing: Creates a smooth, reflective surface for aesthetic or functional purposes.

Custom surface treatment requirements can be accommodated upon request.

Our Service

SteelPRO Group – manufacturer and solution provider for special steel, offering multi-industry application solutions and customised services, 100% quality free, accompanying customers in their growth!

Our Quality Control

- Roundness

- Tolerance

- Microstructure

- Non-Destructive Testing

- Destructive Testing

- Process Control

Service Integration Processing

- Welding

- Metal Fabrication

- CNC Machining

- Lathe

- Forming

QUESTION 1

QUESTION 2

QUESTION 3

QUESTION 4

QUESTION 4

CONTACT

CONTACT

Certifications

Other Products

-

-

SteelPRO Group offers FH550 high-strength structural steel plates for shipbuilding....

-

SteelPRO Group offers DH550 high-strength shipbuilding steel plates in stock....

-

SteelPro Group offers FH36 high-strength steel for shipbuilding. It has...