S500 | High Strength Structural Steel

S500 | High Strength Structural Steel

S500 is a high-strength structural steel used in construction and engineering. “S” stands for structural, and “500” means a 500 MPa yield strength. Equivalent grades are ASTM A572/A572M Grade 50, Q500, ST52-3. It is strong, tough, weldable, and wear-resistant, ideal for bridges, buildings, and heavy machinery.

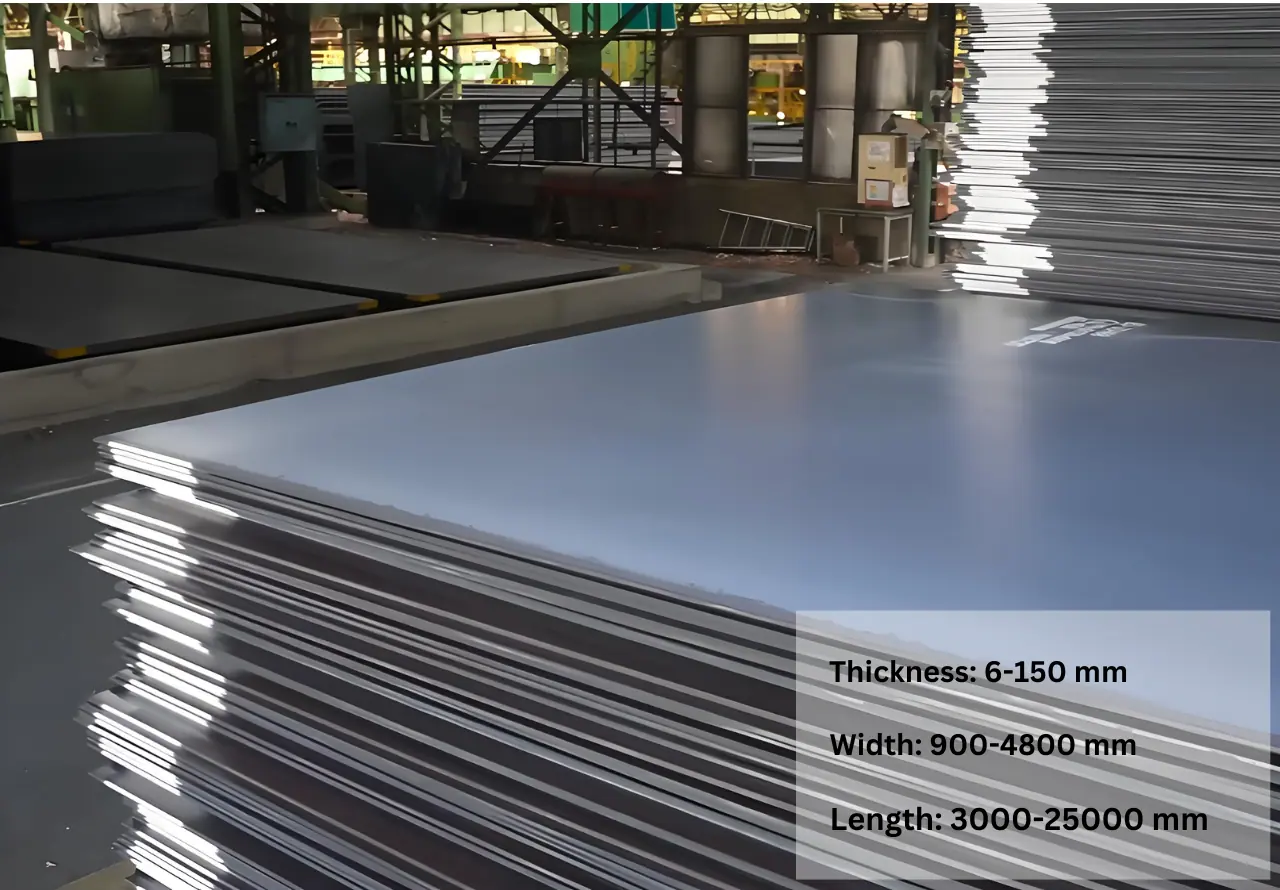

We offer S500Q/QL1/QL2 products with 6 to 150mm thicknesses, 900~4800 mm width, 3000~25000 mm length according to the EN 10025-6 standard.

Description

What is Steel S500?

S500 is a high-strength structural steel made primarily of iron, with small amounts of carbon, manganese, and silicon. It is produced as solid sheets or plates through hot rolling. With a yield strength of 500 MPa, it offers good weldability, toughness, and wear resistance, making it ideal for construction, bridges, and heavy machinery. It complies with the EN 10025-6 S500 standard. Its variants, such as S500Q, S500QL, and S500MC, are tailored for specific applications.Characteristics of S500 Steel

S500 is a high-strength structural steel, offering excellent load-bearing and toughness due to its optimized alloy composition and heat treatment. Its fire resistance allows it to retain strength at high temperatures, making it reliable in demanding conditions. Good weldability results from controlled carbon content, enabling easier fabrication. It is widely used in construction, bridges, and heavy equipment. For better corrosion resistance or performance in cold environments, alternatives like S355, S460, or A572 are recommended, each suited to specific structural and environmental demands.Chemical Compositions

| Element | Content (%) |

|---|---|

| Carbon, C | 0.12 – 0.20 |

| Manganese, Mn | 1.00 – 1.60 |

| Phosphorus, P | ≤ 0.025 |

| Sulfur, S | ≤ 0.010 |

| Silicon, Si | 0.20 – 0.50 |

| Chromium, Cr | 0.30 – 0.50 |

| Nickel, Ni | 0.40 – 0.60 |

| Molybdenum, Mo | 0.15 – 0.30 |

| Vanadium, V | 0.02 – 0.10 |

Physical Properties

| Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Density | 7.85 g/cm³ | 0.283 lb/in³ |

| Melting Point | ~1,500 °C | ~2,732 °F |

| Boiling Point | ~3,000 °C | ~5,432 °F |

| Thermal Conductivity | 40 – 50 W/m·K | 278 – 347 BTU·in/hr·ft²·°F |

| Electrical Conductivity | 5 – 10 MS/m | 5 – 10 MS/m |

| Specific Heat Capacity | 500 J/kg·K | 0.12 BTU/lb·°F |

| Thermal Expansion Coefficient | 12 x 10⁻⁶ /K | 6.7 x 10⁻⁶ /°F |

| Electrical Resistivity | 18 – 25 x 10⁻⁸ Ω·m | 18 – 25 x 10⁻⁸ Ω·m |

Mechanical Properties

| Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Tensile Strength | 500 – 700 MPa | 72,500 – 101,500 psi |

| Yield Strength | ≥ 500 MPa | ≥ 72,500 psi |

| Brinell Hardness | 180 – 250 HB | 180 – 250 HB |

| Rockwell Hardness | 85 – 95 HRB | 85 – 95 HRB |

| Vickers Hardness | 190 – 260 HV | 190 – 260 HV |

| Elongation | 10 – 15% | 10 – 15% |

| Elastic Modulus | 200 GPa | 29,000 ksi |

Data After QT(Quenching and Tempering) Processing

| Property | Metric | Imperial |

|---|---|---|

| Tensile Strength | 700 – 850 MPa | 101,500 – 123,000 psi |

| Yield Strength | ≥ 620 MPa | ≥ 89,923 psi |

| Brinell Hardness | 260 – 320 HB | 260 – 320 HB |

| Rockwell Hardness | 95 – 100 HRB / 35 – 40 HRC | 95 – 100 HRB / 35 – 40 HRC |

| Vickers Hardness | 270 – 330 HV | 270 – 330 HV |

| Elongation | 8 – 12% | 8 – 12% |

| Elastic Modulus | 200 GPa | 29,000 ksi |

Industries & Applications

| Industries | Products |

|---|---|

| Construction | Beams, Columns, Frames, Trusses, Braces |

| Mining | Shovels, Dump Bodies, Drill Pipes, Crushers, Chutes |

| Heavy Equipment | Cranes, Bulldozers, Forklifts, Loaders, Excavators |

| Transportation | Rail Cars, Ship Hulls, Truck Frames, Cargo Containers, Bridges |

| Energy | Wind Towers, Hydropower Structures, Pipelines, Nuclear Plant Frames, Transmission Poles |

| Defense | Armored Vehicles, Bunkers, Military Bridges, Missile Launchers, Tactical Equipment |

| Manufacturing | Press Frames, Molds, Dies, Conveyor Components, Machine Tools |

| Aerospace | Structural Panels, Landing Gears, Engine Mounts, Spacecraft Components, Reinforcements |

| LGS & Seismic Buildings | Wall Panels, Roof Trusses, Floor Systems, Bracings, Reinforcement Frames |

Machining

S500 Steel Heat Treatment Process

- Annealing:

- Heat to 680 – 750°C (1250 – 1380°F), hold, and cool slowly in the furnace to soften the steel, relieve stress, and improve machinability.

- Preheating:

- Heat to 500 – 600°C (930 – 1110°F) to prevent cracking during subsequent processes.

- Austenitizing:

- Heat to 850 – 900°C (1560 – 1650°F) until the structure becomes austenite.

- Quenching:

- Rapidly cool in oil or water to increase hardness and strength by forming martensite.

- Tempering:

- Reheat to 200 – 600°C (390 – 1110°F) to relieve stress and enhance toughness without sacrificing hardness.

S500 Steel Surface Treatments

- Galvanization: Provides corrosion resistance with a zinc coating.

- Powder Coating: Enhances durability and offers color customization.

- Anodizing: Improves surface hardness and wear resistance.

- Shot Peening: Increases fatigue strength through surface compression.

- Electroplating: Adds a protective metal layer for corrosion and wear resistance.

- Polishing: Creates a smooth, reflective surface for aesthetics and functionality.

- Pickling and Passivation: Removes contaminants and prevents corrosion.

Our Service

SteelPRO Group – manufacturer and solution provider for special steel, offering multi-industry application solutions and customised services, 100% quality free, accompanying customers in their growth!

Our Quality Control

- Roundness

- Tolerance

- Microstructure

- Non-Destructive Testing

- Destructive Testing

- Process Control

Service Integration Processing

- Welding

- Metal Fabrication

- CNC Machining

- Lathe

- Forming

QUESTION 1

QUESTION 2

QUESTION 3

QUESTION 4

QUESTION 4

CONTACT

CONTACT

Certifications

Other Products

-

-

SteelPRO Group offers FH550 high-strength structural steel plates for shipbuilding....

-

SteelPRO Group offers DH550 high-strength shipbuilding steel plates in stock....

-

SteelPro Group offers FH36 high-strength steel for shipbuilding. It has...