EN 42CrMo4 (1.7225) Steel Plate

- Alloy or Not: Alloy

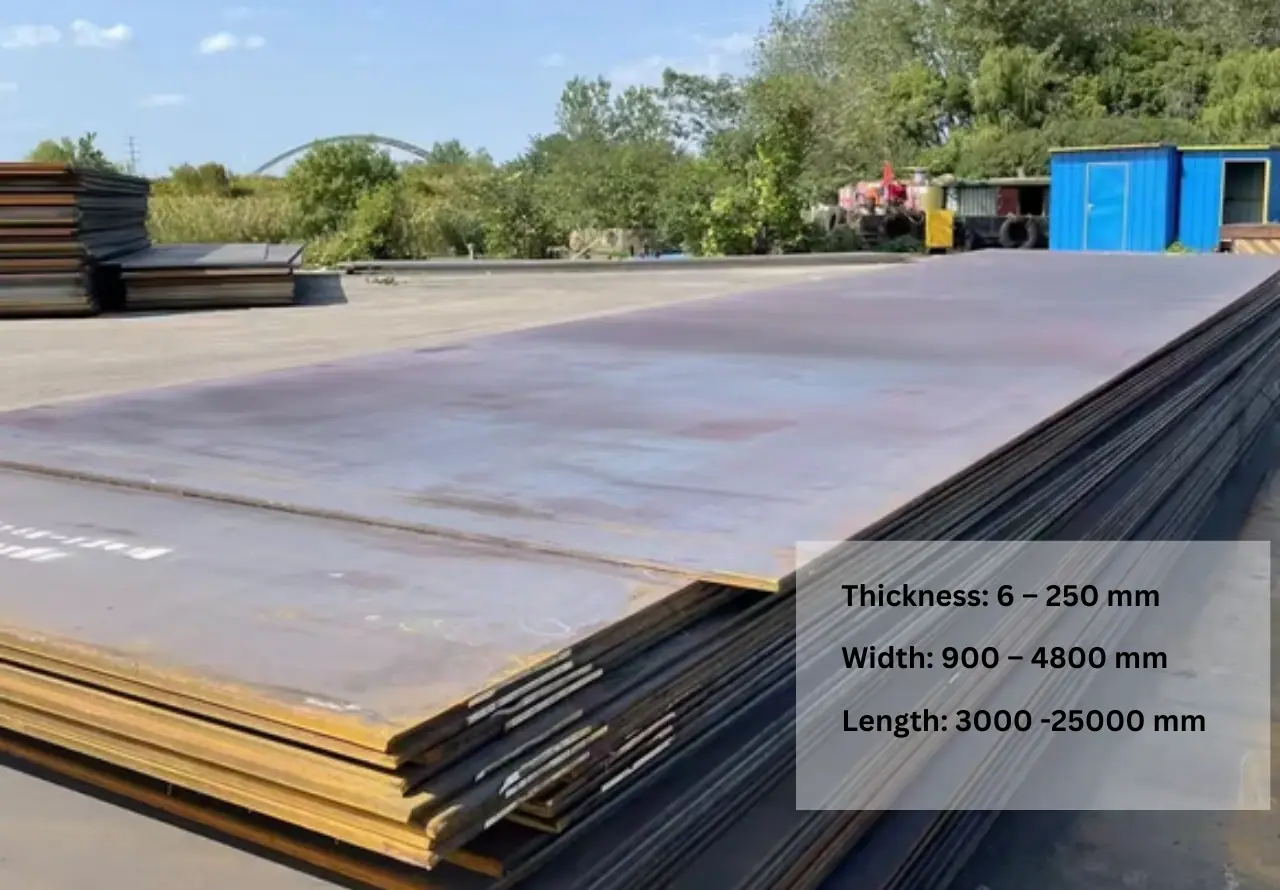

- Thickness: 6 – 250 mm, or as requested

- Width: 900 – 4800 mm, or as requested

- Length: 3000 -25000 mm, or as requested

- Technique: Hot Rolled, Forged, Cold Drawn/Rolled

- Condition: +A/+N/+QT/+HR/+C, or as requested

- Processing Service: Machining, Forging, Grinding, Cutting, Welding, etc.

- Certification: ISO 9001

- Inspection: SGS, TUV, Factory Inspection

- Origin: Hubei/Henan/Jiangsu, China

- Port: Qingdao, Tianjin, Lianyungang

- MOQ: 5 tons (or as per negotiation)

- Delivery Time: 8-14 Days

- Payment: T/T, L/C

Product Detail

If you’re looking for a strong and durable material, the 42CrMo4 steel plate is a solid choice. It’s specifically designed to withstand high pressure, high heat, and heavy loads. The chromium and molybdenum added to the alloy offer impressive strength and hardness, and with heat treatment, we can make it even more durable.

This steel works well for components like gears, bearings, and connecting rods, where fatigue resistance is critical. It’s widely used in industries like oil drilling, heavy machinery, and railways. We also provide custom sizing and surface treatments to meet your exact requirements.

Simply put, the 42CrMo4 plate is a reliable material that performs well even in tough conditions, making it ideal for long-term, high-stress applications.

Contact us if you are unfamiliar with this product or you have questions unsolved.

Naming Rules

Here’s a breakdown of 42CrMo4:

- 42 – Around 0.42% carbon content.

- Cr – Chromium.

- Mo – Molybdenum.

- 4 – Around 0.4% molybdenum content.

Features

42CrMo4 steel plates could bring the following benefits to your project:

- Lasts longer – Fewer part replacements are needed.

- Less maintenance – Highly wear-resistant, reducing repairs.

- Handles heavy loads – Reliable under stress, preventing breakdowns.

- Saves money – Long-lasting performance reduces overall costs.

- Works in any weather – Performs well in hot or cold conditions.

- Supports large parts – Can be used to make big, complex components for high-demand applications.

- Flexible use – Suitable for various industries like automotive and machinery.

- Easy to machine – Simplifies manufacturing, saving time and costs.

Applications

Automotive

Gears, shafts, axles, crankshafts, connecting rods, etc.

Aerospace

Landing gear components, turbine engines, structural parts, etc.

Machinery/Tooling

Machine tool spindles, hydraulic cylinders, heavy-duty tool holders, etc.

Oil and Gas

Drilling equipment, pipeline components, wellhead parts, etc.

Power Generation

Turbine shafts, power transmission components, heavy-duty fasteners, etc.

Manufacturing

Press dies, forging tools, injection molds, heavy-duty machinery components, etc.

Construction

Excavator parts, crane arms, construction tools, wear-resistant plates, etc.

Product Parameters

| Parameter | Details |

|---|---|

| Standard | EN 10083-3:2006, DIN 17200, ASTM A829, GB/T 3077-2015, ISO 683-1, etc. |

| Grade | 42CrMo4, 1.7225, 42CrMo, 4140, SCM440 |

| Thickness | As requested; 6 – 250 mm; Standard 10/12/15/20/25/30/40/50 mm |

| Width | As requested; 900 – 4800 mm; Standard 1000/1250/1500/2000 mm |

| Length | As requested; 3000~25000 mm; Standard 2000/2500/3000/6000 mm |

| Thickness Tolerance | t ≤30mm, ±0.1mm; 30mm < t ≤150mm, ±0.3; or as requested |

| Surface Treatment | Quenched and tempered, Nitrided, Carburized, PVD coated, Chrome plated, Shot peened, Laser hardened, or as requested |

| Condition of Delivery | +A/+N/+QT/+HR/+C, or as requested |

| Testing Method | CCA, HB/HRC/HV, NDT, TST, ITT, etc. |

| Application | Gears, shafts, crankshafts, connecting rods, machine tool spindles, hydraulic cylinders, heavy-duty tool holders, drilling equipment, pipeline components, wellhead parts, turbine shafts, power transmission components, heavy-duty fasteners, forging tools, injection molds, heavy-duty machinery components, excavator parts, crane arms, etc. |

| Certification | Approved by ISO 9001 |

| Packaging | Standard seaworthy packing, or as requested |

*Condition of Delivery: A – Annealed, N – Normalized, QT – Quenched & Tempered, HR – Hot Rolled, C – Cold Worked

*Testing Method: CCA – Chemical Composition Analysis, HB/HRC/HV – Hardness Testing (Brinell, Rockwell, Vickers), NDT – Non-Destructive Testing, TST – Tensile Strength Testing, ITT – Impact Toughness Testing

Material Specifications

Chemical Composition

| Element | C | Si | Mn | P | S | Cr | Mo |

|---|---|---|---|---|---|---|---|

| Wt% | 0.38–0.45 | ≤0.4 | 0.6–0.9 | ≤0.025 | ≤0.035 | 0.9–1.2 | 0.15–0.3 |

*According to EN 10083-3-2006.

Mechanical Properties

| Thickness (mm) | Yield Strength (Mpa) | Tensile Strength (Mpa) | Elongation (%) | Reduction of Area (%) | Impact Toughness (J) at 20℃ |

|---|---|---|---|---|---|

| ≤ 8 | ≥900 | 1100-1300 | ≥10 | ≥40 | ≥30 |

| 8-20 | ≥750 | 1000-1200 | ≥11 | ≥45 | ≥35 |

| 20-60 | ≥650 | 900-1100 | ≥12 | ≥50 | ≥35 |

| 60-100 | ≥550 | 800-950 | ≥13 | ≥50 | ≥35 |

| 100-160 | ≥500 | 750-900 | ≥14 | ≥55 | ≥35 |

Why Choose Us

Consistent Quality

Common issues you may concern, such as surface defects, uneven hardness, and internal stress, can affect performance. We employ methods such as improved heat treatment, sandblasting, and acid pickling to ensure a flawless surface; optimized uniform heat treatment and annealing for consistent hardness; and controlled slow cooling, segmented cooling, and low-temperature tempering to release internal stress.

Precise Dimensions

We guarantee the dimensional accuracy of our 42CrMo4 plates in accordance with international standards. We can maintain tight tolerances up to ±0.01 mm through precision equipment and ISO 9001-certified processes. Every batch undergoes 100% inspection, with zero deviation complaints in the past 5 years. We ensure smooth project execution without installation delays.

Stable Supply

We have 3 factories with a combined annual capacity of over 500,000 tons. In the event of any unforeseen circumstances, we can coordinate across factories to ensure stable production and on-time delivery.

Stable & Competitive Pricing

We maintain upstream raw material suppliers with price-lock agreements in place to effectively manage material cost fluctuations. Also, considering that our clients may face pressure from market changes, we will try our best to offer reasonable discounts to both new and existing clients.

Secure Packaging & Shipping

Packaging can be customized according to your requirements. We provide transparent, real-time photos of the packaging and loading process for your verification. You can also choose your trusted freight forwarder for transportation to ensure the entire logistics process is secure and reliable.

About Us

Founded in 1999, SteelPRO Group operates three factories with a combined annual production capacity of over 500,000 tons. We specialize in manufacturing a wide range of steel products, including round steel, profiles, plates, and pipes. Our portfolio encompasses low-alloy structural steel, tool steel, special steel, and more.

With strict adherence to global standards such as GB, ASTM, DIN, EN, and JIS, we ensure high-quality products, including heat-treated, machined, and prestressed steel. Our solutions are trusted by customers in diverse industries, and we proudly export to different countries across Europe, North America, and Asia.

At SteelPRO, we are dedicated to delivering tailored steel solutions and growing alongside our

Certification

FAQ

What are your prices?

Our prices are subject to change depending on supply and market conditions. For an accurate and up-to-date quote, please contact our sales team directly.

Can you provide relevant documentation?

Yes, we can provide a wide range of documentation, including Certificates of Analysis/Conformance, Insurance, Certificates of Origin, and any other required export documents.

What is the average lead time?

As per mass production, the lead time is 5-20 days after:

1) we have received your deposit; 2) we have received your final confirmation on your orders.

If our lead time doesn’t meet your deadlines, please contact our sales directly in advance in case of any potential issues. We will try to accommodate your needs in all cases, and we are able to do so in most cases.

Can you provide free samples?

Yes, we can provide free samples for quality evaluation. However, shipping costs are generally covered by your company.

Can I visit your factory?

Of course! You are welcome to visit our factory. Please contact us in advance to arrange a convenient time for your visit, and we will gladly organize a tour and provide any necessary information to ensure a productive visit.

Our Service

SteelPRO Group – manufacturer and solution provider for special steel, offering multi-industry application solutions and customised services, 100% quality free, accompanying customers in their growth!

Our Quality Control

- Roundness

- Tolerance

- Microstructure

- Non-Destructive Testing

- Destructive Testing

- Process Control

Service Integration Processing

- Welding

- Metal Fabrication

- CNC Machining

- Lathe

- Forming