EH40 | High-Strength Shipbuilding Steel

EH40 | High-Strength Shipbuilding Steel

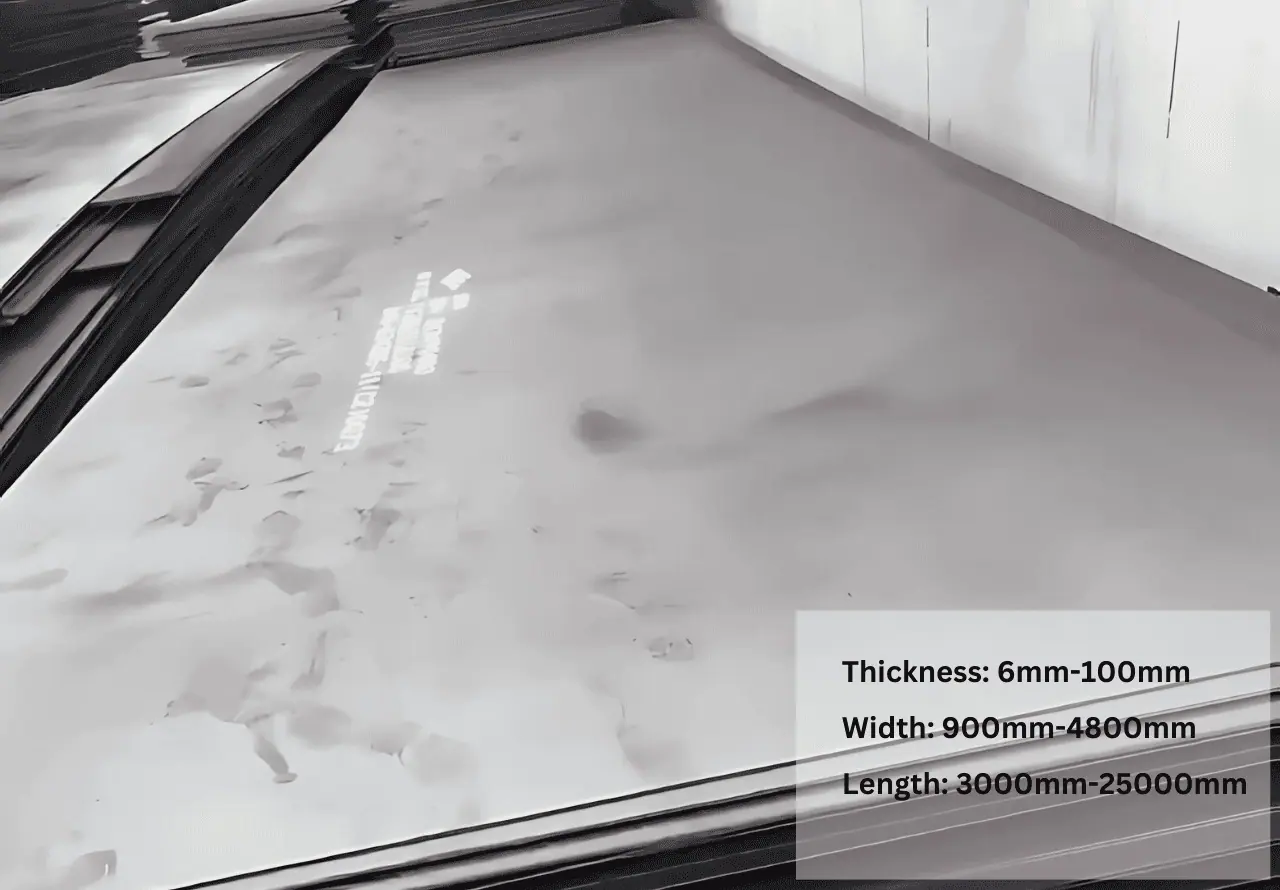

SteelPRO Group provides EH40 high-strength shipbuilding steel plates in stock.

Class Cert.: ABS/BV/CCS/DNV/KR/LR/NK/RINA/RS/PRS

Material: Low Alloy Steel

Thickness: 6mm-100mm, or customized

Width: 900mm-4800mm, or customized

Length: 3000mm-25000mm, or customized

Condition of Delivery: A/HR/N/CR/Q+T/TMPC, or as request

Stock: In stock

Origin: Hebei/Henan/Jiangsu, China

Port: Qingdao

Looking for other Grade 40 high-strength steel?

Click here for AH40/DH40/FH40.

Description

What Is EH40?

EH40 steel is a high-strength structural steel primarily used in shipbuilding and marine engineering. “E” stands for toughness level at -40℃, “H” indicates its high strength.

EH40 offers excellent tensile strength (over 400 MPa) and a minimum yield strength of 390 MPa, making it durable under heavy loads. It retains toughness at low temperatures, ensuring stability in harsh marine environments. Its good weldability allows for defect-free construction, and anti-corrosion coatings protect it from seawater, ensuring long-term reliability.

It is widely used in building hulls, decks, and bulkheads for both oceangoing and coastal vessels. It also plays a vital role in offshore platforms, subsea pipelines, and other marine infrastructure that require high strength and corrosion resistance.

Characteristics of EH40

- High strength for heavy-duty applications

- Good weldability with minimal risk of cracking

- Excellent toughness, even in low temperatures

- Resistant to corrosion and harsh environments

- Suitable for offshore and structural uses

EH40 Steel Manufacturer

Our EH40 steel is ideal for critical structural components like ice belts, reinforced hull sections, and stiffeners in ice-class ships, offshore platforms, and polar-class vessels. With a thickness range of 6 mm to 150 mm, we ensure flexibility to meet diverse design requirements. Each batch is produced in compliance with ASTM A131 and EN 10025, certified to EN 10204 Type 3.2 for full traceability.

SteelPro Group works closely with shipyards globally to ensure timely delivery of certified EH40 plates and profiles. We strictly control product dimensional tolerances and offer tailored solutions to meet your specific needs.Certifications

Chemical Compositions

| Element | Content (%) |

|---|---|

| Carbon, C | ≤ 0.18 |

| Manganese, Mn | ≤ 1.60 |

| Silicon, Si | 0.10 – 0.50 |

| Phosphorus, P | ≤ 0.035 |

| Sulfur, S | ≤ 0.035 |

| Chromium, Cr | ≤ 0.20 |

| Nickel, Ni | ≤ 0.40 |

| Copper, Cu | ≤ 0.35 |

| Molybdenum, Mo | ≤ 0.08 |

| Vanadium, V | ≤ 0.05 |

| Aluminum, Al | ≥ 0.015 |

Physical Properties

| Property | Metric | Imperial |

|---|---|---|

| Density | 7.8 – 7.9 g/cm³ | 0.282 – 0.285 lb/in³ |

| Melting Point | 1450 – 1520 °C | 2642 – 2768 °F |

| Thermal Conductivity | 50.2 W/m·K | 29.1 BTU/h·ft·°F |

| Electrical Conductivity | 2.44 x 10⁶ S/m | 2.44 x 10⁶ S/m |

| Specific Heat Capacity | 500 J/kg·K | 0.119 BTU/lb·°F |

| Thermal Expansion Coefficient | 11.7 µm/m·°C | 6.5 µin/in·°F |

| Electrical Resistivity | 0.39 µΩ·m | 0.39 µΩ·m |

Mechanical Properties

| Thickness (mm) | Yield Strength (MPa min.) | Tensile Strength (MPa) | Elongation (% min.) | Test Temperature (°C) | Impact Energy (KV J min.) Transverse/Longitudinal |

|---|---|---|---|---|---|

| ≤50 | 390 | 510 – 650 | 20 | -40 | 27/41 |

Industries & Applications

| ndustry | Common EH40 Steel Products |

|---|---|

| Shipbuilding | Hull plates, Bulkheads, Decks, Offshore platforms |

| Oil & Gas | Pipelines, Storage tanks, Rig structures, Subsea equipment |

| Construction | Bridges, High-rise buildings, Structural supports, Heavy machinery |

| Defense | Naval vessels, Armored vehicles, Military bunkers, Weapons platforms |

| Energy | Wind turbine towers, Hydropower plants, Nuclear plant components, Transmission towers |

Machining

Heat Treatment

- Normalizing: Heat the steel to 890-950°C, followed by air cooling. This refines the grain structure and improves toughness.

- Quenching: Heat to 900-940°C, followed by water or oil quenching. This increases hardness and strength.

- Tempering: Reheat to 550-650°C, then air cool. This reduces brittleness while retaining hardness and toughness.

- Stress Relieving: Heat to 540-620°C and cool in air to reduce internal stresses.

Surface Finish

- Shot Blasting: Removes rust, scale, and impurities, enhancing paint adhesion.

- Pickling: An acid treatment that cleans the surface of oxides and contaminants, leaving a smooth finish.

- Protective Coating: Apply coatings like epoxy or zinc-rich primers to guard against corrosion.

- Grinding/Polishing: Reduces surface roughness and achieves a finer texture for specific applications.

*Customization is available upon request.

Our Service

SteelPRO Group – manufacturer and solution provider for special steel, offering multi-industry application solutions and customised services, 100% quality free, accompanying customers in their growth!

Our Quality Control

- Roundness

- Tolerance

- Microstructure

- Non-Destructive Testing

- Destructive Testing

- Process Control

Service Integration Processing

- Welding

- Metal Fabrication

- CNC Machining

- Lathe

- Forming

QUESTION 1

QUESTION 2

QUESTION 3

QUESTION 4

QUESTION 4

CONTACT

CONTACT

Certifications

Other Products

-

-

SteelPRO Group offers FH550 high-strength structural steel plates for shipbuilding....

-

SteelPRO Group offers DH550 high-strength shipbuilding steel plates in stock....

-

SteelPro Group offers FH36 high-strength steel for shipbuilding. It has...