AH40 | High-Strength Shipbuilding Steel

AH40 | High-Strength Shipbuilding Steel

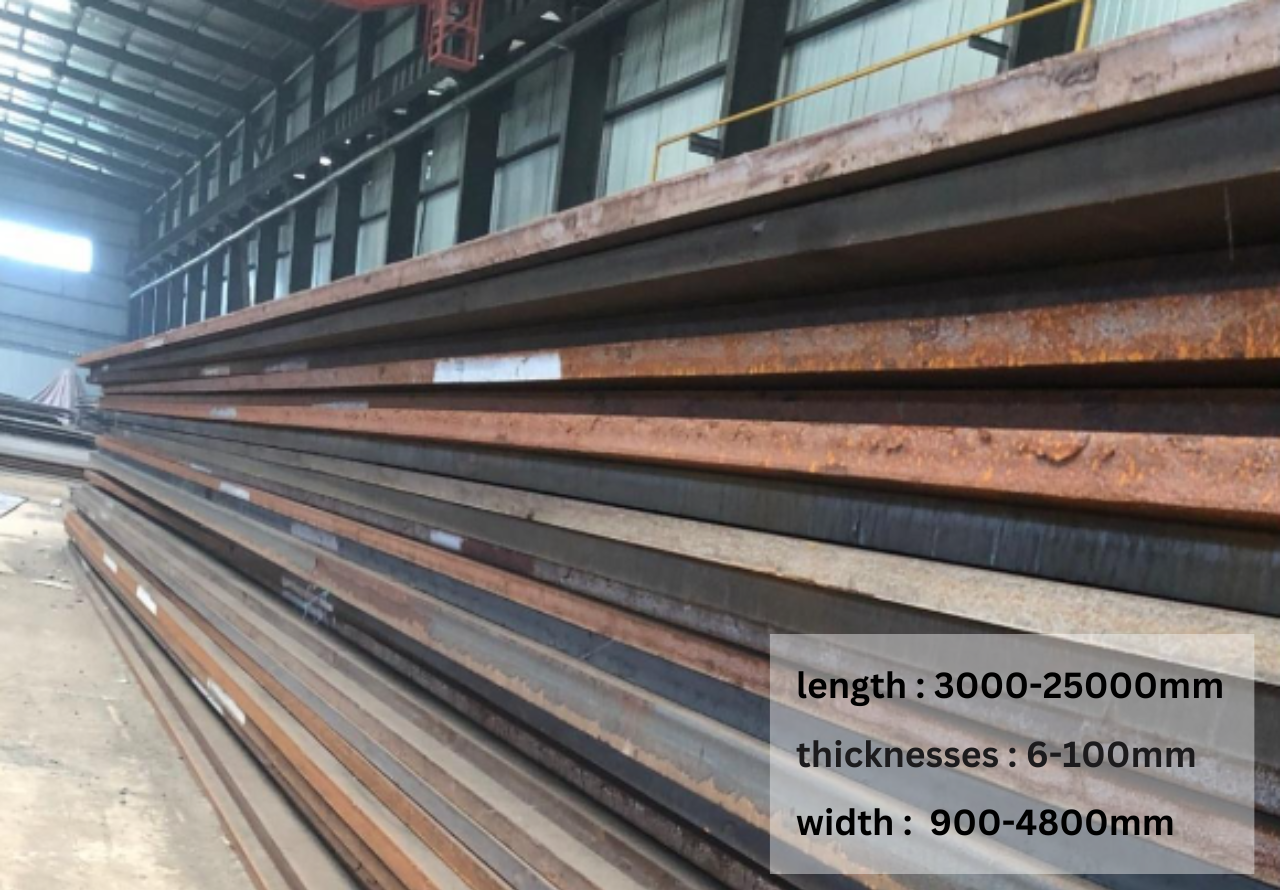

SteelPRO Group provides AH40 high-strength shipbuilding steel plates in stock.

Class Cert.: ABS/BV/CCS/DNV/KR/LR/NK/RINA/RS/PRS

Material: Low Alloy Steel

Thickness: 6mm-100mm, or customized

Width: 900mm-4800mm, or customized

Length: 3000mm-25000mm, or customized

Condition of Delivery: A/HR/N/CR/Q+T/TMPC, or as request

Stock: In stock

Origin: Hebei/Henan/Jiangsu, China

Port: Qingdao

Looking for other Grade 40 high-strength steel?

Click here for DH40/EH40/FH40.

Description

What Is AH40?

AH40 steel is a high-strength, high-toughness material widely used in shipbuilding and offshore structures. The “A” represents the quality grade, while “H” indicates high-strength steel, with “40” referring to a yield strength of 40 kgf/mm² (about 390 MPa).

It offers excellent corrosion resistance, tensile and bending strength, and good weldability, performing reliably in harsh marine conditions. This makes it suitable for applications like ship hulls, decks, and offshore platforms, where durability, impact resistance, and reduced maintenance are essential for long-term performance.

Characteristics of AH40

- High strength and toughness

- Excellent corrosion resistance

- Good weldability and machinability

- Strong resistance to bending, torsion, and impact

- Reliable performance in harsh marine environments

AH40 Steel Manufacturer

SteelPro Group supplies AH40 steel certified by international classification societies. Our products include plates, bulb flats, L-sections, and T-sections, ensuring guaranteed safety and quality. We offer shot blasting, primer coating, and other corrosion-resistant finishes. With extensive experience in serving heavy-duty vessels such as tankers, container ships, and offshore support vessels, we look forward to collaborating with you!-

- Classifier: ABS, LR, CCS, KR, NK

- Standard: ASTM A131, EN 10025

- Certificate: EN 10204 Type 3.2

- Impact Strength: 34 J at 0°C

Certifications

Chemical Compositions

| Element | Max % |

|---|---|

| Carbon, C | 0.18 |

| Silicon, Si | 0.5 |

| Manganese, Mn | 0.90 – 1.60 |

| Phosphorus, P | 0.03 |

| Sulfur, S | 0.03 |

| Aluminum, Als | 0.015 |

| Niobium, Nb | 0.02 – 0.05 |

| Vanadium, V | 0.05 – 0.10 |

| Titanium, Ti | 0.02 |

| Copper, Cu | 0.35 |

| Chromium, Cr | 0.2 |

| Nickel, Ni | 0.4 |

| Molybdenum, Mo | 0.08 |

Physical Properties

| Property | Metric | Imperial |

|---|---|---|

| Density | 7,850 kg/m³ | 0.284 lb/in³ |

| Melting Point | 1,510 °C | 2,750 °F |

| Thermal Conductivity | 50 W/m·K | 289 BTU·in/hr·ft²·°F |

| Electrical Conductivity | 6.8 MS/m | 11.7% IACS |

| Specific Heat Capacity | 480 J/kg·K | 0.114 BTU/lb·°F |

| Thermal Expansion Coefficient | 12 x 10⁻⁶ /°C | 6.67 x 10⁻⁶ /°F |

| Electrical Resistivity | 145 nΩ·m | 1.45 μΩ·cm |

Mechanical Properties

| Thickness (mm) | Yield Strength (MPa min.) | Tensile Strength (MPa) | Elongation (% min.) | Test Temperature (°C) | Impact Energy (KV J min.) Transverse/Longitudinal |

|---|---|---|---|---|---|

| ≤50 | 390 | 510 – 650 | 20 | 0 | 27/41 |

Industries & Applications

| Industry | Application |

|---|---|

| Shipbuilding | Hulls, Decks, Bulkheads, Offshore Platforms |

| Marine Engineering | Ship Frames, Submarines, Engine Foundations, Offshore Structures |

| Oil & Gas | Oil Rigs, Pipelines, Drilling Platforms, Storage Tanks |

| Heavy Equipment Manufacturing | Cranes, Excavators, Loaders, Bulldozers |

Machining

Heat Treatment

- Normalizing: 900-950°C, air cool.

- Stress Relieving: 540-600°C, hold for 1-2 hours, then air cool.

- Quenching: 850-900°C, quench in water or oil.

- Tempering: 550-650°C, depending on required properties.

Surface Finish

- Polishing: Improves smoothness and shine.

- Grinding: Removes material for a smooth finish.

- Sandblasting: Produces a matte or textured surface.

- Brushing: Creates a linear texture with a satin finish.

- Anodizing: Increases corrosion resistance and surface hardness.

- Plating: Adds a metal coating for enhanced durability or aesthetics.

- Powder Coating: Provides a uniform, durable protective layer.

- Passivation: Enhances corrosion resistance by removing contaminants.

*Customization is available upon request.

Our Service

SteelPRO Group – manufacturer and solution provider for special steel, offering multi-industry application solutions and customised services, 100% quality free, accompanying customers in their growth!

Our Quality Control

- Roundness

- Tolerance

- Microstructure

- Non-Destructive Testing

- Destructive Testing

- Process Control

Service Integration Processing

- Welding

- Metal Fabrication

- CNC Machining

- Lathe

- Forming

QUESTION 1

QUESTION 2

QUESTION 3

QUESTION 4

QUESTION 4

CONTACT

CONTACT

Certifications

Other Products

-

-

SteelPRO Group offers FH550 high-strength structural steel plates for shipbuilding....

-

SteelPRO Group offers DH550 high-strength shipbuilding steel plates in stock....

-

SteelPro Group offers FH36 high-strength steel for shipbuilding. It has...