SGCC Galvanized Steel Coil

SGCC Galvanized Steel Coil

SteelPRO Group is a manufacturer of SGCC galvanized steel coils that meet international standards. We offer a wide range of galvanized products that you can customize in terms of surface treatment, size, shape, etc., suitable for construction, home appliances and automotive fields. In addition to galvanized steel coils, we also offer a series of products such as plates, pipes, PPGI, roofing panels, etc., covering multiple grades to meet the diverse needs of customers and provide professional technical support.

- Standard: JIS G 3302, GB/T 2518, ASTM A653, EN 10346, etc.

- Grades: SGCC, SPCC, CS Type A, CS Type B, DX51D, etc

- Technology: Cold Rolling, Hot-dip Galvanizing

- Certification: ISO 9001, CE

SGCC Galvanized Steel Coil

SGCC Galvanized Steel Coil

Product Specifications

Product Specifications

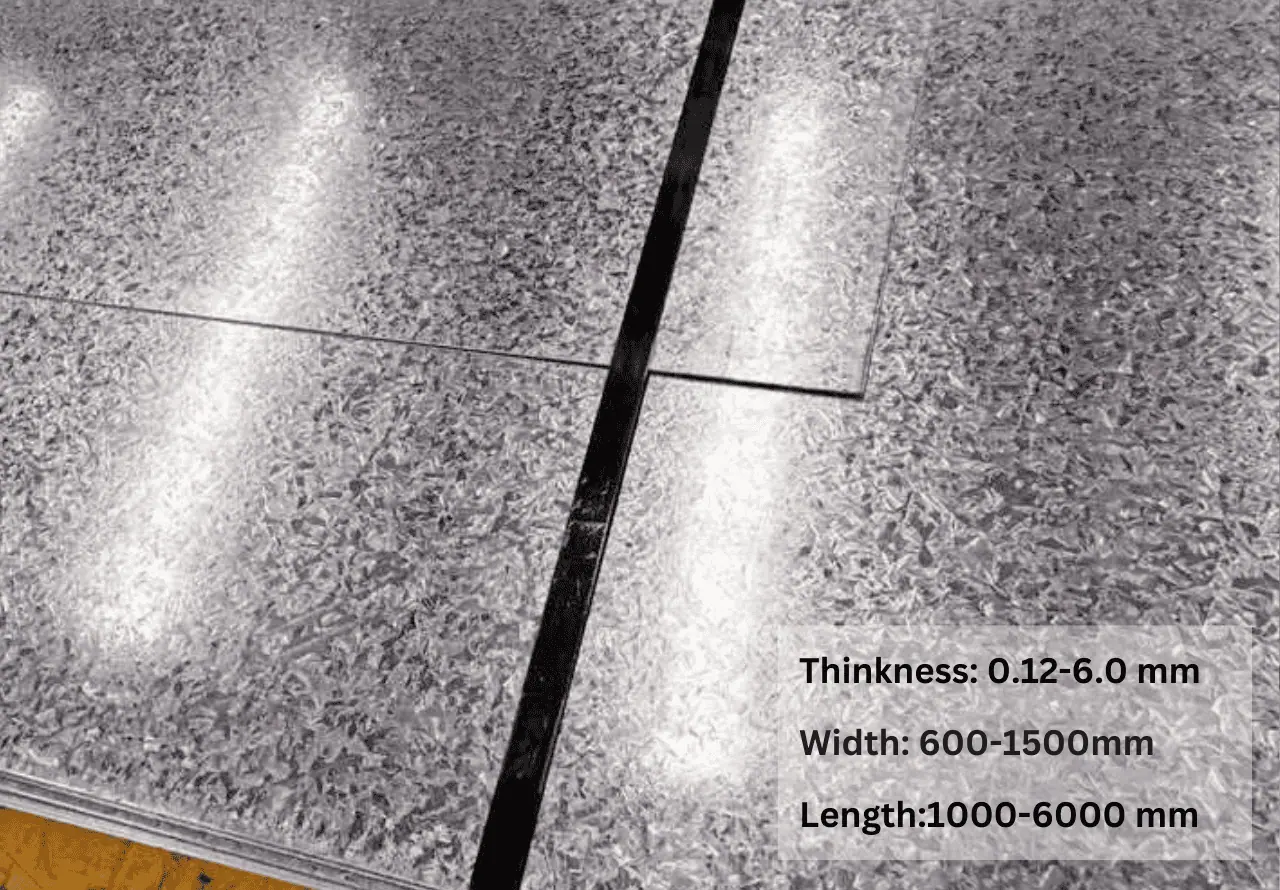

| Product Name | SGCC Galvanized Steel Coil |

| Thickness | 0.3mm~3mm, Customized |

| Width | 600mm – 1500mm, Customized |

| Length | Customized |

| Coil Inner | 508mm – 610mm, Customized |

| Zinc Layer | 30g – 275g/m² |

| Spangle | big, regular, mini, and zero spangles |

| Surface Treatment | anti-finger print /skin pass/oiled/ dry/chromated/Embossed/Lamination |

| Surface quality | A, B |

| Test | Zinc Coating Thickness Test, Bend, Cross-hatch, Salt Spray Test, Tensile Test, etc. |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Invoicing | by actual weight |

| Delivery Time | 7-15 days |

| Payment | T/T, L/C, Credit Card |

| Port | Shanghai, Qingdao or according to your requirement |

| Packaging Details | In bundles, in bulk, customized packing |

Chemical Compositions

Chemical Compositions

| Element | Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon (Si) |

|---|---|---|---|---|---|

| Composition (%) | ≤ 0.15 | ≤ 0.80 | ≤ 0.05 | ≤ 0.04 | ≤ 0.03 |

Mechanical properties

Mechanical properties

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 270 – 500 |

| Yield Strength (MPa) | ≥ 205 |

| Elongation (%) | ≥ 22 |

| Vickers Hardness (HV) | 80 – 120 |

| Brinell Hardness (HB) | 70 – 100 |

| Rockwell Hardness (HRB) | 50 – 70 |

| Elastic Modulus (GPa) | ~ 210 |

Industries & Applications

Industries & Applications

Construction: Used for roofing, wall panels, doors, window frames, and structural components due to its durability and corrosion resistance.

Home Appliances: Commonly used for the outer casings of refrigerators, washing machines, air conditioners, and other household appliances.

Automotive Industry: Suitable for vehicle body parts, underbody components, and inner structural elements due to its strength and corrosion protection.

Electrical Equipment: Applied in enclosures for electrical and control panels to provide protection from moisture and corrosion.

Furniture and Storage: Used in the production of metal furniture, shelving, and storage units requiring durability and rust prevention.

Agricultural Equipment: Applied to machinery and equipment exposed to outdoor conditions, providing rust resistance and extending lifespan.

Other Infomation

Other Infomation

SteelPRO Group offers a variety of surface treatments and coating options that meet international quality standards. Customers can choose the most suitable products according to the application environment, usage time and appearance requirements to obtain the best cost-effectiveness and product performance.

Anti-Rust Coating

Anti-Rust coating is a basic protective layer that is suitable for most environments, especially for products that are stored for a short period of time or for general applications. It can effectively prevent mild oxidation of metals during storage and initial use, maintaining the appearance and basic durability of the product.

Anti-Corrosion Coating

Anti-corrosion treated coatings are suitable for highly corrosive environments such as high humidity, acid rain or salt spray. This coating forms a protective film on the surface to prevent chemical corrosion of steel. Suitable for outdoor building structures, building materials in coastal areas or industrial equipment exposed to water and chemicals.

Anti-Fingerprint Coating

Anti-Fingerprint Coating forms a transparent protective layer on the surface to prevent fingerprints and oil stains from adhering to maintain a clean appearance. This treatment is particularly suitable for home appliances, electronic equipment or decorative materials with high appearance requirements. It is easy to clean and has excellent anti-fouling properties.

Color Coating (PPGI)

Color coating provides a variety of color options for products while increasing corrosion resistance. PPGI coatings are suitable for building materials, home appliance panels, signboards and other fields that require beautiful appearance. They can effectively extend the service life and make the products more decorative.

Special coatings

For specific needs, we also provide special coating treatments, such as UV-resistant coatings, wear-resistant coatings and antibacterial coatings. These coatings are suitable for scenarios with special performance requirements, such as building materials exposed to sunlight for a long time, industrial equipment requiring high wear resistance, or applications in the food and medical fields.

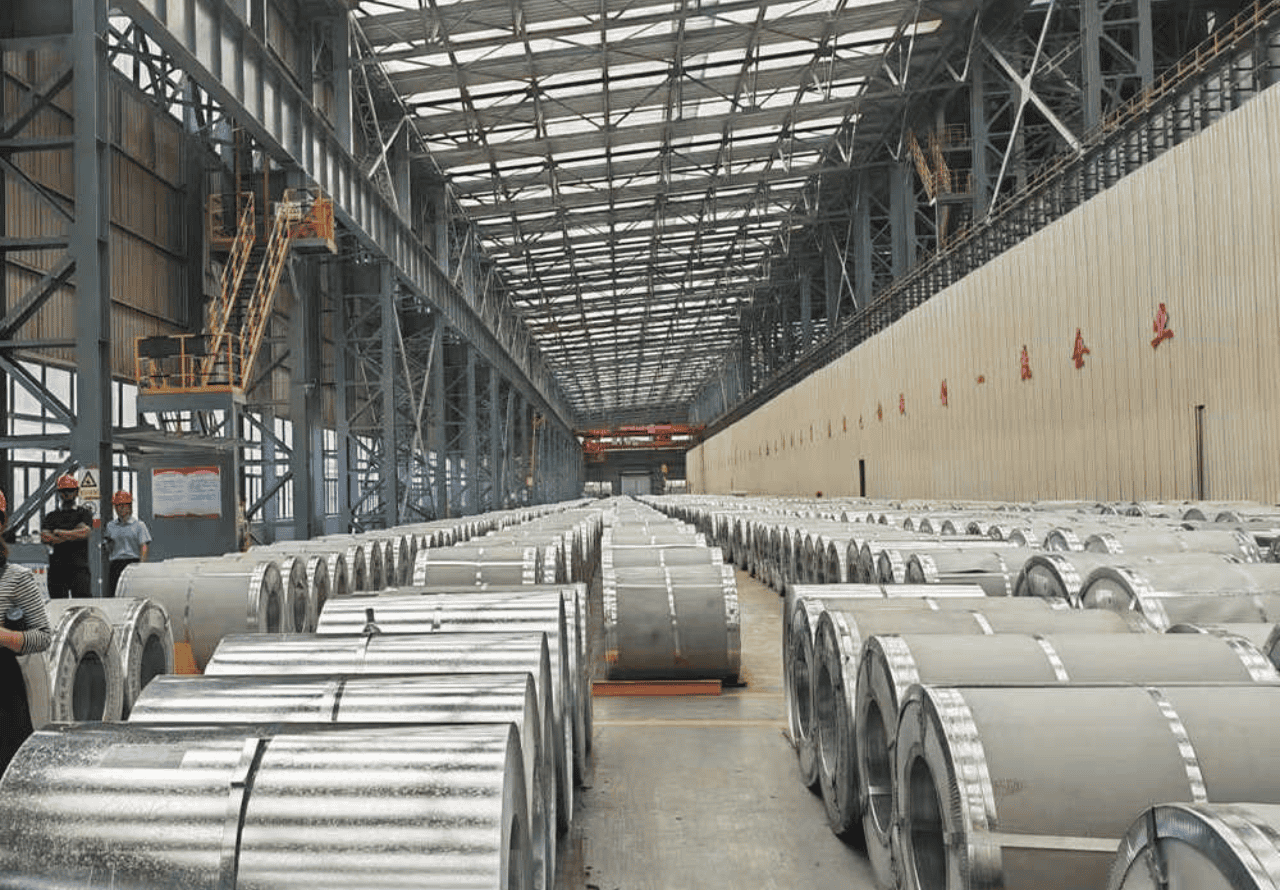

Our Inventory

Our Inventory

Galvanized steel manufacturer and supplier SteelPRO Group has a wide range of products with stable quality, strong durability, corrosion resistance, impact resistance, and adaptability to a variety of environments. We have strong production capabilities, relying on advanced automated production lines and efficient production capacity to ensure that each product meets strict international standards and provide customers with stable supply guarantees. With rich production experience and strong resource integration capabilities, we are able to meet the diverse needs of customers, including quick response to large-volume orders and customized products, ensuring the smooth progress of your project.

Main products: steel coils, steel plates, rebar, carbon steel, stainless steel, galvanized steel, structural steel, and specialty steel for industries such as construction, automotive, manufacturing, and energy.

Packing

Packing

Our packaging is strictly in accordance with international standards to ensure the safety and integrity of the products during transportation. Each batch of products is treated with multiple layers of protection such as moisture-proof and collision-proof to meet the needs of long-distance transportation. With years of export experience, SteelPRO Group provides efficient and reliable packaging solutions to ensure that customers receive intact products and help projects proceed smoothly.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

How does SteelPRO Group ensure product quality?

All our products are subject to strict quality control and meet international standards. Each batch of steel coils undergoes multiple quality tests before leaving the factory, including thickness, adhesion and corrosion resistance, to ensure product stability and reliability.

Can SGCC galvanized steel coils be used in high humidity environments?

Yes, our SGCC galvanized steel coils perform well in high humidity environments. Products that have been passivated and anti-fingerprint treated are more corrosion-resistant and easy to clean, making them ideal for humid or frequently cleaned places.

What subsequent processing processes are suitable for SGCC galvanized steel coils?

SGCC galvanized steel coils are suitable for a variety of processing processes, such as stamping, bending, cutting, etc. Our products have a strong coating and are not easy to fall off after processing, making them ideal materials for excellent performance in subsequent processes.

How stable are our SGCC galvanized steel coils at high temperatures?

SGCC galvanized steel coils are suitable for use in normal temperature environments. If they need to be used at high temperatures, we recommend the use of special high-temperature treated materials to ensure the stability and long-term durability of the coating.

Do SteelPRO Group's products pass international quality certifications?

Yes, our products have passed ISO and other international quality certifications and meet relevant industry standards. These certifications ensure the quality and performance of the products to meet the stringent requirements of global customers.

Can SteelPRO Group provide samples?

We can provide SGCC galvanized steel coil samples for testing free of charge according to customer needs, so that customers can understand in advance whether the performance of the product meets the project requirements. However, the freight needs to be borne by the customer.

CONTACT

Certificates and Cooperation

Certificates and Cooperation