DX52D Galvanized Steel Pipe

DX52D Galvanized Steel Pipe

SteelPRO Group specializes in manufacturing DX52D galvanized steel pipes that can withstand harsh environments. You can choose regular sizes or customize. We also provide other galvanized steel products such as DX51D Gi coils, DC01Gi plates, PPGI, roofing sheets, etc., in accordance with EN, JIS, ASTM, GB and other standards.

- Standards: EN 10346, EN 10143, DIN EN 10219, ASTM A653

- Grades: DX52D, DX52D+Z, CS Type A/B, SGCD2, SECC

- Technology: Hot Dip Galvanizing, Cold Rolled, Hot Rolled, ERW, Electro-galvanizing

- Certification: ISO 9001, CE

DX52D Galvanized Steel Pipe

DX52D Galvanized Steel Pipe

Product Specifications

Product Specifications

| Product Name | DX52D Hot Dip Galvanized Steel Pipe | Tube |

| WT (Wall Thickness) | 1mm – 12mm, Customized |

| OD (Outer Diameter) | 8mm – 914mm, Customized |

| Length | 1m – 12m, Customized

Regular: 5.8m, 6m, 8m, 12m, etc. |

| Zinc Coating | 20-400g/m², g30, g40, g60, g90, etc. |

| Surface Treatment | Anti-finger print / Skin pass / Oiled / Dry / Chromated / Embossed / Lamination |

| Spangle | Zero Spangle / Mini Spangle / Regular Spangle / Large Spangle |

| Pipe ends | Smooth end / Threaded end / With connector |

| Shape | Round, Square, Rectangle, Oval, Hexagon, etc. |

| Test | Zinc Coating Thickness Test, Salt Spray Test, Adhesion Test, Tensile Test, Impact Test, Bend Test, Welding Test, etc. |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Invoicing | By actual weight |

| Delivery Time | 7-15 days |

| Payment | T/T, L/C, Credit Card |

| Port | Shanghai, Qingdao or according to your requirement |

| Packaging Details | In bundles, in bulk, customized packing |

Chemical Compositions

Chemical Compositions

| Element | Carbon (C) | Silicon (Si) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Aluminum (Al) |

|---|---|---|---|---|---|---|

| Percentage (%) | ≤ 0.12 | ≤ 0.50 | ≤ 0.60 | ≤ 0.10 | ≤ 0.045 | ≥ 0.015 |

Mechanical properties

Mechanical properties

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 270 – 410 |

| Yield Strength (MPa) | ≤ 260 |

| Elongation (%) | ≥ 26 |

| Vickers Hardness (HV) | 100 – 160 (approximate) |

| Brinell Hardness (HB) | 90 – 150 (approximate) |

| Rockwell Hardness (HRB) | ≤ 74 |

| Elastic Modulus (GPa) | ~ 210 |

Industries & Applications

Industries & Applications

- Automotive parts: Inner body panels, structural reinforcements, and chassis components.

- Appliances: Washing machines, refrigerators, and other household appliances.

- Construction: Roofs, siding, and metal frames for buildings.

- HVAC systems: Air ducts, ventilation components, and other heating, ventilation, and air conditioning components.

- Furniture: Metal furniture frames, office equipment, and storage units.

- Electrical enclosures: Boxes, cabinets, and other enclosures for electrical equipment.

- Packaging: Steel drums, containers, and packaging for a variety of products.

- Tubes and pipes: Pipes and tubes made for lightweight structural applications.

Other Infomation

Other Infomation

If you want to cut our products after purchase, we recommend that you:

- Use professional tools such as angle grinders and metal cutting saws to ensure the cutting effect and the galvanized layer of the steel pipe is not damaged.

- Metal chips and smoke will be generated during cutting. Please be sure to wear protective masks and goggles and operate in a well-ventilated place. Slow down the cutting speed appropriately, or use coolant to control the temperature to prevent overheating from affecting the protective effect of the galvanized layer.

- After cutting, the exposed part of the steel pipe loses the protection of galvanization. Don’t forget to apply anti-rust paint or cold spray zinc on the cut. Simple treatment can avoid subsequent rust problems.

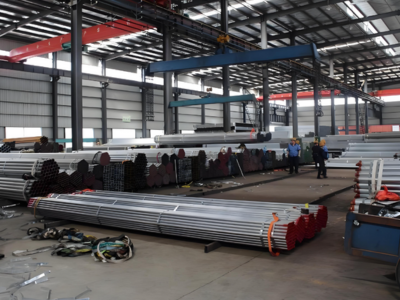

Our Inventory

Our Inventory

As a professional steel supplier and manufacturer, SteelPRO Group puts customers first, strictly controls quality, and has an annual production capacity of more than 1 million tons. We work closely with multiple supply chain partners to ensure that when inventory is short, it can be replenished quickly and delivery is efficient and timely.

Main products: steel pipes, steel plates, steel coils, steel bars, steel strips, stainless steel series, carbon steel series, high-strength steel series, nuclear grade steel, galvanized steel, steel for wind and solar energy, etc.

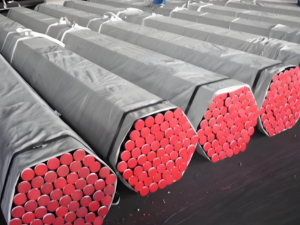

Packing

Packing

Standard packaging: DX52D galvanized steel pipes are usually packed with waterproof packaging, wooden pallets and steel straps to ensure that the steel pipes are not damaged during transportation. All packaging meets international transportation standards to ensure that the products remain intact during long-distance transportation.

Special packaging: If you have special packaging requirements (such as moisture-proof, shock-proof, etc.), we can provide customized packaging services upon request. Please state your special needs when placing an order.

Shipping arrangements: We will flexibly arrange batch shipments or whole batch shipments according to the size and weight of the order. Whether it is a one-time shipment or a batch shipment, we will communicate with you in advance and ensure the most optimized logistics arrangements to avoid unnecessary delays and increased costs.

Cargo tracking: We provide customers with cargo tracking numbers so that customers can track the shipping status of their orders in real time.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

How to get a sample?

To get samples, you need to send us your detailed shipping address (including zip code) and the DHL/FedEx/UPS account you use to collect samples, and the courier cost will be paid by you.

How can I get a quotation from you ?

You can leave us a message and we will reply to every message in time. Or leave your email and we will send you a quotation. You can also find our contact information on the contact page.

Can provide OEM/ODM service?

Yes. Please feel free to contact us for more details discuss.

What is the typical lead time for an order?

Lead times vary depending on order size and product availability. Typically, standard products are shipped within 7-14 business days. Custom orders may take longer and we will provide an estimated delivery time after order confirmation.

Do you offer custom or cut-to-size services?

Yes, we offer custom cutting, sizing and processing services to meet specific project requirements. Please provide details and we will arrange the necessary customization.

How do I know which steel is right for my project?

The choice of steel grade depends on your application. You can refer to our product descriptions for detailed specifications or contact our team for expert guidance based on your needs.

CONTACT

Certificates and Cooperation

Certificates and Cooperation