Introduction to Mold Steel

Mold steel is engineered for high performance in tough manufacturing environments. With a hardness rating of up to 60 HRC, it offers exceptional wear resistance, significantly reducing the need for frequent replacements. Its high heat tolerance, typically up to 600°C (1112°F), ensures stability in high-temperature applications like die casting and plastic injection molding. This leads to 20-30% longer mold life, reducing downtime and maintenance costs.

Mold steel’s machinability allows for precision molds with tight tolerances, improving production efficiency and product quality. Its resistance to corrosion also minimizes material degradation, extending its lifespan even in harsh conditions. By choosing mold steel, manufacturers benefit from enhanced durability, lower maintenance costs, and consistent high-quality output, which can improve overall productivity by up to 15-20%.

Benefits of Mold Steel

- Longer mold life with high strength

- Heat resistant for tough environments

- Less maintenance thanks to corrosion resistance

- Strong and durable to avoid cracks

- Easy to work with for complex molds

- Great for many uses like plastic injection and die casting

Types & Grades of Mold Steel

Mold steel is categorized into different types and grades. We’ll just pick some common of them as follows:

- Carbon Mold Steel

Common Grades: S50C, S55C, 1045, 1050

Applicability: General plastic molds, small components. - Alloy Mold Steel

Common Grades: P20, 718 (P20+Ni), 2738, 4140

Applicability: Medium-precision plastic molds, automotive, electronics. - Hot Work Mold Steel

Common Grades: H13, SKD61, 1.2344, 1.2367

Applicability: High-temperature applications, die casting, forging. - Cold Work Mold Steel

Common Grades: D2, SKD11, 1.2379, O1

Applicability: Cutting, punching, shearing. - Stainless Mold Steel

Common Grades: 420, 1.2083, 1.2316, 440C

Applicability: High corrosion resistance, high polish molds.

Industries & Applications

Some common industries and applications include:

Automotive

Electronics

Aerospace

Medical

Packaging

Consumer Goods

Construction

Furniture

Mold Steel Product Specifications

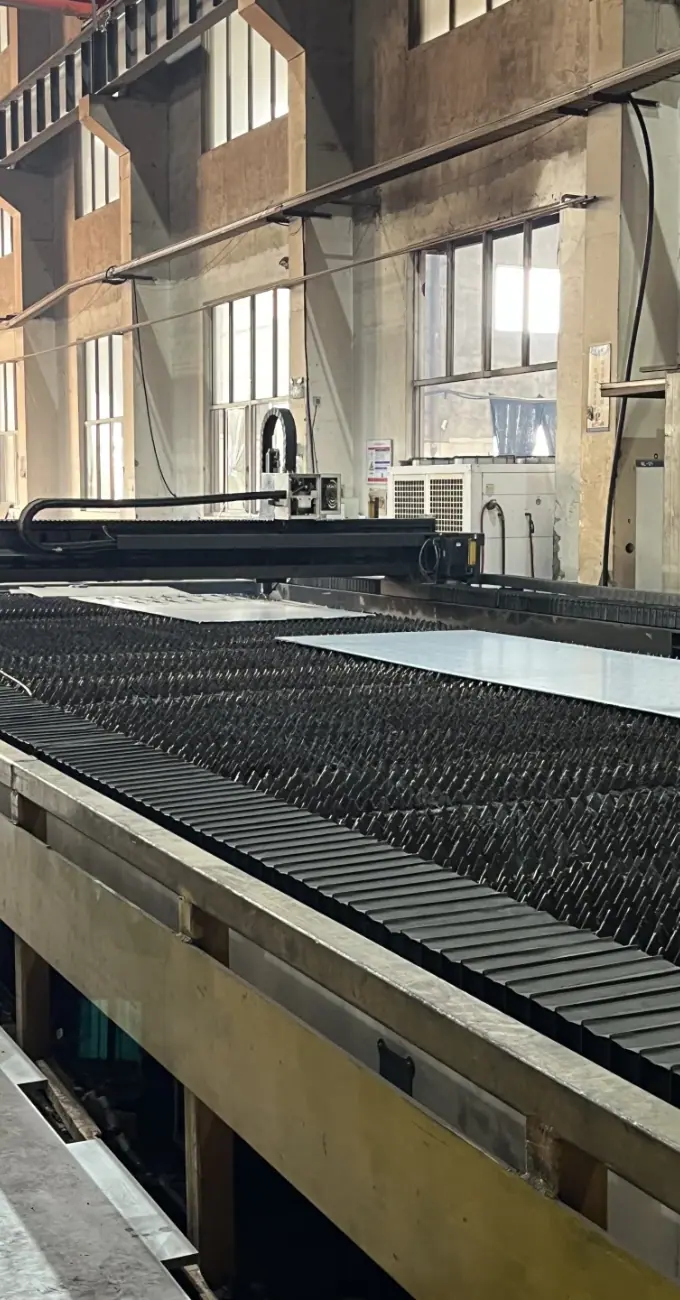

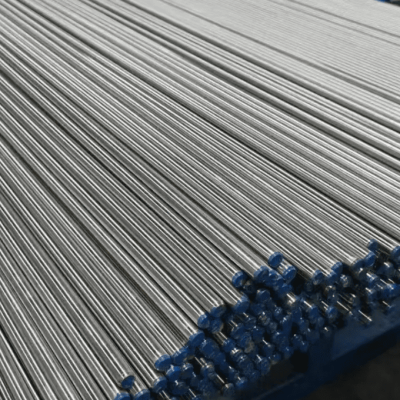

SteelPRO Group offers most of the commonly used grades for mold steel in major shapes, including round/flat bars, plates/sheets, strips, forgings, wires, etc. Browse the list below for the grades and specifications we cover. The list doesn’t cover it fully. For details, please contact our sales team. We’ll contact you shortly.

| Grade | Specifications (mm) | Standard | ||

| Thickness | Width | Length | ||

| 35/40/45/50/55 | 6–250 | 900–4800 | 3000–25000 | GB/T 711 or Negotiation |

| SM45/48/50/53/55 | YB/T 107 | |||

| SM3Cr2Mo | ||||

| S35C/S38C/S40C/S45C/S50C/S55C | JIS G 4051 or Negotiation | |||

| 40Cr/42CrMo/42CrMo4/SCM440/YGHM45/YGHM50 | GB /T 3077 or Negotiation | |||

| P20/1.2311/718/738 | ASTM A681 or Negotiation | |||

Mold Steel When & Where You Need It

At SteelPRO Group, you get more than just quality steel. With multiple facilities across the country capable of providing mold steel, we can also work with you to manage your inventory, ensuring you get the product when and where you need it to keep your production running.

Explore Our Available Steel Products & Grades

Our knowledge and experience give nearly 100% accurate delivery of High Carbon, Low Carbon, Stainless Steel products processed and packaged to your exact specifications.