16MO3 | Alloy Pressure Vessel Steel

16MO3 | Alloy Pressure Vessel Steel

16Mo3 is a low-alloy pressure vessel steel known for its high-temperature strength and corrosion resistance. The name “16Mo3” indicates 0.16% carbon content, with “Mo” representing molybdenum as an alloying element. Similar grades include ASTM A204Gr.A, ASTM A204Gr.B, DIN 15Mo3, NF 15D3, A302, A204. Its molybdenum content provides good heat and corrosion resistance. 16Mo3 is widely used in boilers, pressure vessels, heat exchangers, and other components exposed to high temperatures.

Description

What is 16Mo3?

16Mo3 is a pressure vessel-grade chromium-molybdenum steel specified under EN 10028. It contains 0.16% carbon and molybdenum. Known for its heat and corrosion resistance due to chromium and molybdenum, it is produced by hot rolling and also classified as boiler steel. 16Mo3 is used in high-temperature applications like power plants, refineries, and pressure vessels. It has good weldability and durability, making it suitable for heat exchangers and high-temperature components.Why Choose 16Mo3 Alloy Pressure Vessel Steel?

When it comes to high-temperature applications like power plants and petrochemical facilities, why choose 16Mo3? We recommend 16Mo3 for its excellent heat and corrosion resistance, performing well at up to 600°C and withstanding stress over 220 MPa. It’s perfect for power plants and petrochemical facilities. Its low-alloy composition offers good weldability, simplifying fabrication and lowering costs. Plus, we ensure reliable quality and timely delivery.Product Specification

| Category | Details |

| Quality Standard | EN 10028-2-2009 |

| Certifications | ISO 9001, CE, AD 2000-W0, PED, SGS, ASTM A204 |

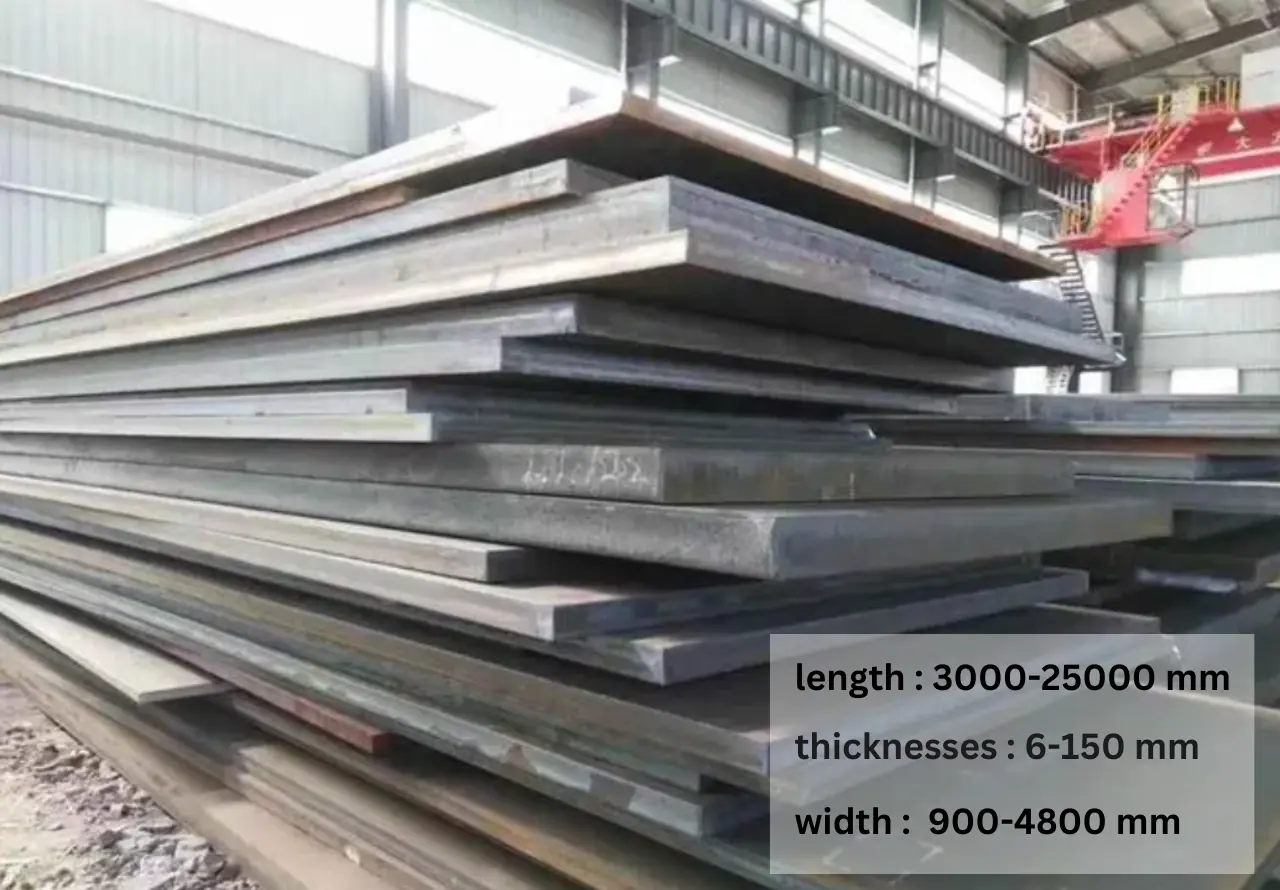

| Thickness | 6-150mm |

| Width | 900-4800mm |

| Length | 3000-25000mm |

| Weight | Depends on length and width |

| Outer diameter (OD) | Pipes: 21 mm to 610 mm, Bars: 20 mm to 400 mm |

| Inner diameter (ID) | Pipes: 12 mm to 600 mm |

| Tolerances | Thickness: ±0.3mm to ±0.7mm, Width: ±5mm to±10mm, Length: ±10mm to ±20mm |

| Technology | Hot Rolled |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Shapes | Alloy Pressure Vessel Steel Plate, Alloy Pressure Vessel Steel Sheet, Pipes, Profiles |

| MOQ (Minimum Order Quantity) | 5 tons (according to the actual tonnage) |

| Lead Time | Typically 7-20 days |

| Price Terms & Payment | Based on customer requirements, T/T, L/C |

| Ports | Qingdao, Lianyungang, Dalian |

| Export Countries | Southeast Asia, Central Asia, Europe, Russia, South America, Middle East, etc. |

| Shipping Method | Offers Sea, Air and Customized Shipping |

Chemical Compositions

| Element | Content (%) |

|---|---|

| Carbon, C | 0.12 – 0.20 |

| Silicon, Si | 0.20 – 0.35 |

| Manganese, Mn | 0.40 – 0.90 |

| Phosphorus, P | ≤ 0.025 |

| Sulfur, S | ≤ 0.010 |

| Chromium, Cr | ≤ 0.30 |

| Molybdenum, Mo | 0.25 – 0.35 |

| Nickel, Ni | ≤ 0.30 |

| Copper, Cu | ≤ 0.30 |

| Nitrogen, N | ≤ 0.012 |

Mechanical Properties

| Property | Metric (MPa, HB, HR, HV, %) | Imperial (ksi, HB, HR, HV, %) |

|---|---|---|

| Tensile Strength (≤16 mm thickness) | 440 – 590 MPa | 63.8 – 85.6 ksi |

| Tensile Strength (>16 mm thickness) | 430 – 570 MPa | 62.4 – 82.7 ksi |

| Yield Strength (≤16 mm thickness) | ≥ 240 MPa | ≥ 34.8 ksi |

| Yield Strength (>16 mm thickness) | ≥ 220 MPa | ≥ 31.9 ksi |

| Brinell Hardness (HB) | 150 – 180 HB | 150 – 180 HB |

| Rockwell Hardness (HRB) | 75 – 87 HRB | 75 – 87 HRB |

| Vickers Hardness (HV) | 155 – 180 HV | 155 – 180 HV |

| Elongation (≥3 mm thickness) | ≥ 22% | ≥ 22% |

| Elastic Modulus | 200 GPa | 29,000 ksi |

Data After Normalizing Processing

| Property | Metric (MPa, HB, HR, HV, %) | Imperial (ksi, HB, HR, HV, %) |

|---|---|---|

| Tensile Strength (≤16 mm thickness, normalized) | 460 – 620 MPa | 66.7 – 89.9 ksi |

| Tensile Strength (>16 mm thickness, normalized) | 450 – 600 MPa | 65.3 – 87.0 ksi |

| Yield Strength (≤16 mm thickness, normalized) | ≥ 260 MPa | ≥ 37.7 ksi |

| Yield Strength (>16 mm thickness, normalized) | ≥ 240 MPa | ≥ 34.8 ksi |

| Brinell Hardness (HB, normalized) | 160 – 190 HB | 160 – 190 HB |

| Rockwell Hardness (HRB, normalized) | 78 – 90 HRB | 78 – 90 HRB |

| Vickers Hardness (HV, normalized) | 165 – 190 HV | 165 – 190 HV |

| Elongation (≥3 mm thickness, normalized) | ≥ 20% | ≥ 20% |

| Elastic Modulus (normalized) | 200 GPa | 29,000 ksi |

Industries & Applications

| Industries | Products |

|---|---|

| Power Generation | Boilers, Heat exchangers, Superheater tubes, Turbine casings, Piping systems |

| Petrochemical Industry | Pressure vessels, Reactors, Heat recovery systems, Storage tanks, Distillation columns |

| Oil and Gas Industry | Pipeline components, Gas processing units, Offshore platforms, Separators, Compressors |

| Chemical Processing | Chemical reactors, Condensers, Heat exchangers, Towers, Autoclaves |

| Industrial Boilers | Steam drums, Economizers, Water walls, Furnace tubes, Superheater coils |

| Nuclear Power Plants | Reactor vessels, Containment structures, Steam generators, Pressure piping, Control rod mechanisms |

| Fossil Fuel Plants | Coal-fired boilers, Heat recovery steam generators, Steam turbines, Piping systems, Flue gas desulfurization systems |

| Marine Engineering | Shipbuilding boilers, Exhaust gas cleaning systems, Marine engine parts, Fuel processing equipment, Storage tanks |

| Thermal Power Plants | Heat recovery boilers, Piping systems, Superheater tubes, Turbine housings, Heat exchangers |

Packing

At SteelPRO Group, we take great care in packing 16Mo3 to ensure safe transportation and maintain the steel’s integrity. Here are four key advantages we offer:

- Custom Packaging Solutions: We tailor packaging to match the specific size and shape of 16Mo3 steel products, minimizing movement and potential damage during transit.

- Protection from Corrosion: We use high-quality protective coatings and anti-corrosion wraps to safeguard 16Mo3 against moisture and rust, especially for long-distance or overseas shipments.

- Reinforced Strapping and Crating: Our packing includes reinforced strapping and strong wooden crates, ensuring that the steel remains stable and secure, even in harsh transport conditions.

- Compliance with International Standards: We adhere to global packaging and shipping standards, ensuring that our packing meets the strict requirements of various industries, including power plants and petrochemical sectors.

These measures ensure safe and efficient delivery, keeping the steel in prime condition for your projects.

Machining

16Mo3 Heat Treatment Product Options

SteelPRO Group offers a wide range of 16Mo3 alloy pressure vessel steel with various heat treatment options to suit your project needs. Here’s what we provide:

- Normalized 16Mo3 Steel: Improves mechanical properties such as strength and hardness, making it suitable for high-temperature environments.

- Annealed 16Mo3 Steel: Softened for better machinability and easier forming, ideal for complex fabrication processes.

- Quenched and Tempered 16Mo3 Steel: Increased strength and toughness for applications that require high wear resistance and durability.

- Stress-Relieved 16Mo3 Steel: Reduced residual stresses, improving dimensional stability and performance under pressure.

- Cold Rolled 16Mo3 Steel: Available for applications that demand precise dimensions and a smooth surface finish.

- Hot Rolled 16Mo3 Steel: Suitable for applications requiring thicker sections and improved toughness in harsh conditions

16Mo3 Surface Finish

Here are the surface treatments we offer for 16Mo3 steel:

- Shot Blasting: Removes scale, rust, and impurities, providing a clean surface ready for coating or painting.

- Pickling: Removes oxidation and scale from the surface, improving corrosion resistance and preparing the steel for further treatment.

- Galvanizing: Adds a protective zinc coating, enhancing corrosion resistance in harsh environments.

- Painting: Provides a layer of protection against rust and environmental damage, also available in various colors for aesthetic or identification purposes.

- Oil Coating: Prevents oxidation during storage and transport, maintaining the steel’s surface integrity.

- Passivation: Enhances corrosion resistance by forming a protective oxide layer on the surface.

- Phosphating: Improves paint adhesion and provides temporary rust protection during handling and storage.

16Mo3 Alloy Pressure Vessel Steel Manufacturer

As a leading supplier of 16Mo3 Alloy Pressure Vessel Steel, SteelPRO Group offers unparalleled expertise and commitment across multiple key areas:

- Competitive Pricing and Customer Focus: We provide competitive pricing while prioritizing client satisfaction with dedicated support throughout your project.

- Wide Range of Products: Our 16Mo3 steel range covers various forms, including plates, pipes, and bars, ensuring we meet all your project requirements.

- Strict Quality Assurance and Certifications: Each batch is thoroughly tested and certified according to industry standards such as EN 10204 3.1/3.2, ensuring reliable, high-quality materials.

- Custom Solutions: We offer tailored steel solutions, including specific dimensions, finishes, and treatments, ensuring 16Mo3 meets your exact needs.

- Safe Packaging and Efficient Logistics: Our robust packaging ensures safe delivery, and our efficient logistics system guarantees timely and transparent shipping updates.

SteelPRO Group is your trusted partner for all 16Mo3 alloy pressure vessel steel needs, backed by experience, precision, and customer-first service.

Our Service

SteelPRO Group – manufacturer and solution provider for special steel, offering multi-industry application solutions and customised services, 100% quality free, accompanying customers in their growth!

Our Quality Control

- Roundness

- Tolerance

- Microstructure

- Non-Destructive Testing

- Destructive Testing

- Process Control

Service Integration Processing

- Welding

- Metal Fabrication

- CNC Machining

- Lathe

- Forming

How Does 16Mo3 Perform Under High-Pressure Conditions?

16Mo3 is specifically designed for pressure vessels and can withstand high pressures due to its excellent mechanical properties, such as high yield strength and toughness.

Can You Ensure Consistency In Mechanical Properties Across Different Batches?

Yes, we maintain strict quality control and testing protocols to ensure consistency in mechanical properties across all batches of 16Mo3 steel.

What Is The Usual Turnaround Time For Technical Inquiries Or Quotations?

We strive to respond to all technical inquiries and quotations within 24-48 hours, depending on the complexity of the request.

How Do You Handle Urgent Material Requirements Or Emergency Orders?

We offer expedited processing for urgent orders, depending on stock availability and production capacity, ensuring minimal disruption to your project timelines.

Can You Provide Traceability Documentation For 16Mo3 Materials?

Absolutely, we offer full traceability for all 16Mo3 materials, including detailed mill certificates to meet customer and regulatory requirements.

Do You Support Partial Shipments For Large Orders?

Yes, we can arrange partial shipments to ensure timely delivery based on your project timeline, especially for large or custom orders.

CONTACT

CONTACT

Certifications

Other Products

-

-

SteelPRO Group offers FH550 high-strength structural steel plates for shipbuilding....

-

SteelPRO Group offers DH550 high-strength shipbuilding steel plates in stock....

-

SteelPro Group offers FH36 high-strength steel for shipbuilding. It has...