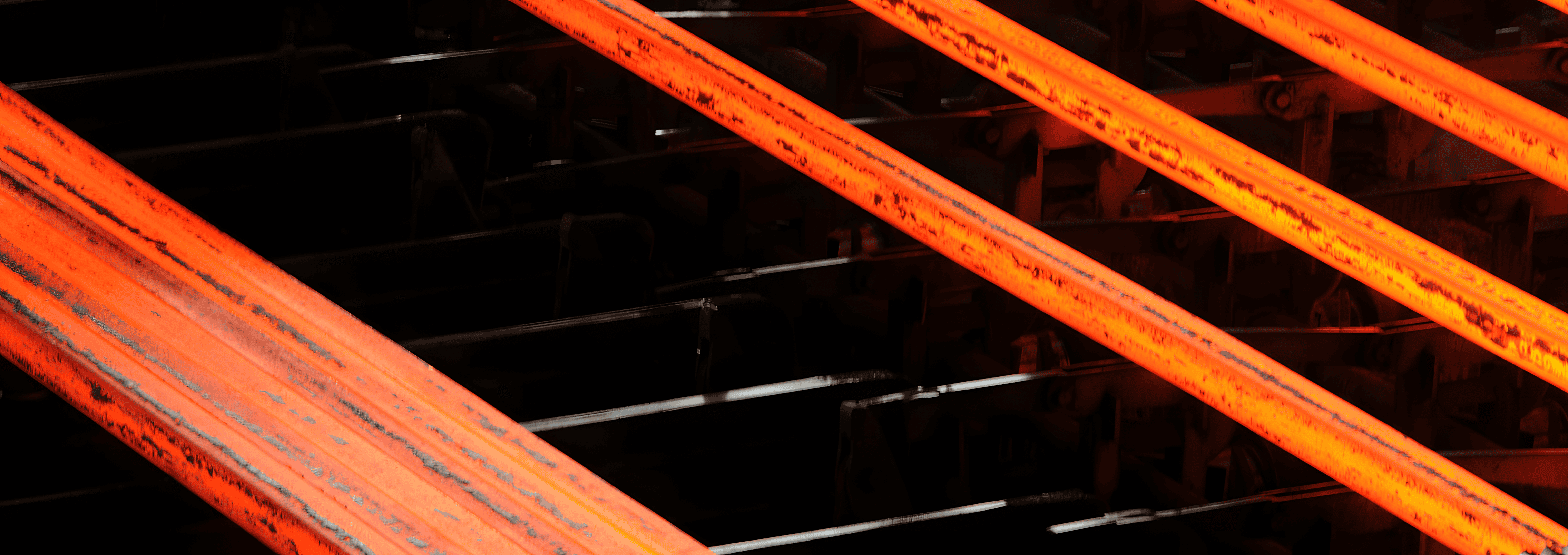

STAINLESS STEELS BAR

As a trusted supplier of stainless steel rods, we use advanced manufacturing techniques to ensure exceptional quality and durability. Our stainless steel bars, with excellent corrosion resistance and strength, are ideal for medical instruments, kitchen equipment, automotive components, and construction projects.

We offer competitive prices without compromising quality. Our extensive inventory and efficient production and logistics ensure fast, reliable delivery.

Choose our stainless steel bars for top quality, great pricing, and fast delivery. Order now for superior corrosion resistance and quick shipping.

What are Stainless Steels Bars

Stainless Steels Bar Type

| Type | Size Ranges | Applications | |

|---|---|---|---|

| Diameter from 0.2 inches to 12 inches | Shafts, axles, and fasteners | get a quote |

| Across flats from 0.24 inches to 4 inches | Brackets, base plates, and braces | get a quote |

| Side length from 0.2 inches to 6 inches | Nuts, bolts, and fasteners | get a quote |

| Thickness 0.08 to 4 inches, Width 0.4 to 12 inches | Tool handles, ornamental ironwork | get a quote |

Stainless Steels Bar Grades

| Standard | USA | SIZE | |

|---|---|---|---|

| ASTM A276 | 304 | 1/8" - 12" | get a quote |

| ASTM A276 | 309 | 1/8" - 12" | get a quote |

| ASTM A276 | 347 | 1/8" - 12" | get a quote |

| ASTM A276 | 410 | 1/8" - 10" | get a quote |

| ASTM A276 | 430 | 1/8" - 10" | get a quote |

| ASTM A276 | 431 | 3/16" - 20" | get a quote |

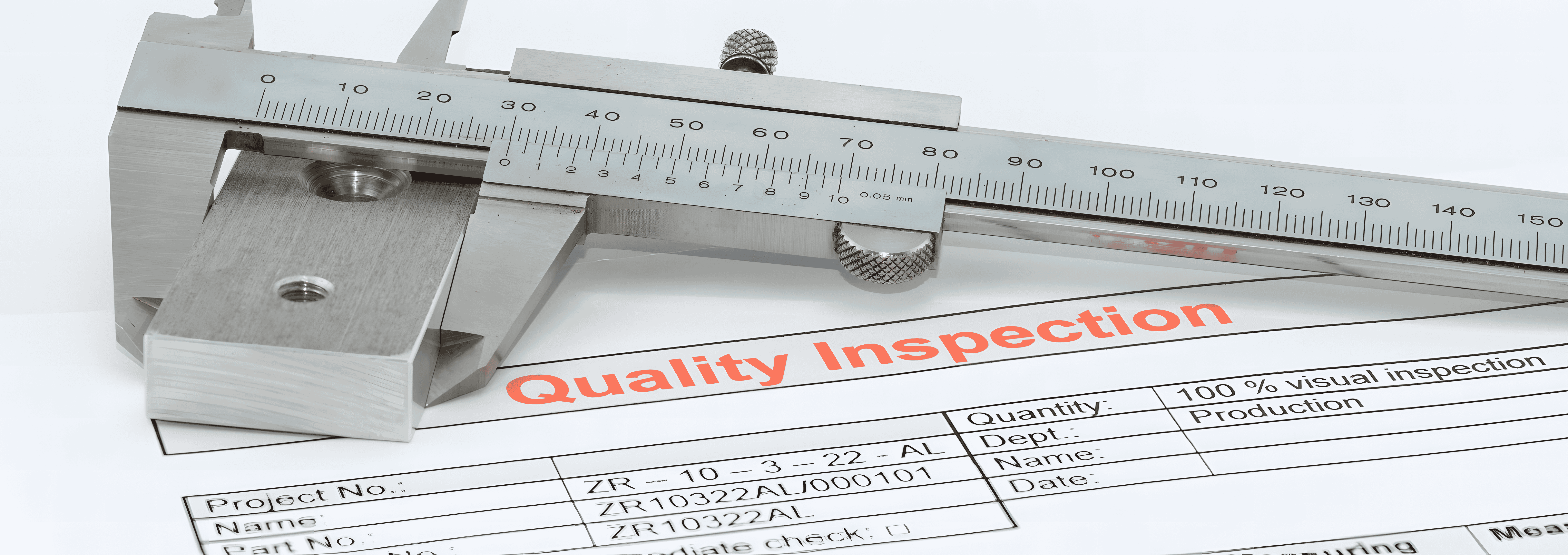

Quality Assurance for Stainless Steels Bars

Regular Quality Inspections:

- Dimensional Accuracy: Verifying precise measurements of diameter, thickness, and length.

- Surface Finish: Checking for smoothness and absence of defects like cracks or scales.

- Mechanical Properties: Testing tensile strength, yield strength, and hardness.

- Chemical Composition: Confirming the correct alloy mix through spectroscopic analysis.

Extreme Testing:

- Impact Testing: Assessing the material’s toughness and resistance to sudden impacts.

- Fatigue Testing: Evaluating the bar’s endurance under repeated stress cycles.

- Corrosion Resistance: Subjecting the bars to corrosive environments to test durability.

- Temperature Resistance: Testing the bars’ performance under extreme temperatures.

If you have specific requirements, we can customize additional tests to meet your needs.

- Protective Coatings: Our steel bars are coated to prevent corrosion and damage during transit. Additional coating options are available upon request.

- Secured Bundling: Bars are securely bundled with steel straps and wooden supports. Finished products are shipped in wooden crates.

- Labeling and Documentation: Each shipment is clearly labeled and comes with detailed documentation for easy tracking.

Several factors impact the performance of stainless steel bars:

- Microstructure: Grain size and phase composition determine properties.

- Dimensional Effects: Bar diameter affects cooling rate and heat treatment.

- Quality Control: Ensures consistency and uniformity.

- Impurities: Affect mechanical properties and fatigue life.

- Storage and Transport: Improper conditions can cause damage or corrosion.

- Heat Treatment: Affects strength, hardness, and workability.

- Processing Techniques: Hot/cold rolling influence properties and surface quality.

Some stainless steels are magnetic and may not suit certain applications. Choosing non-magnetic or low-magnetic austenitic stainless steel grades can avoid magnetism issues.

Proper storage of stainless steel bars is crucial to maintain their quality and performance. Environmental conditions and transportation methods play a significant role.

- Dry Environment: Store in a dry, well-ventilated area to prevent rust and corrosion.

- Stable Temperature: Maintain a stable temperature to avoid thermal stress and deformation.

- Humidity Control: Use dehumidifiers or desiccants to minimize moisture exposure.

- Proper Packaging: Protect bars with suitable packaging during transit to avoid damage.

- Horizontal Storage: Store bars horizontally to prevent bending.

- Separated Storage: Store different specs separately to avoid confusion.

- Away from Corrosive Substances: Keep bars away from corrosive chemicals.

Usage & Application of Stainless Steels Bar

Stainless steel bars are essential for their durability and corrosion resistance, widely used in various industries:

- Automotive: Engine components and exhaust systems.

- Construction: Structural supports and reinforcements.

- Machinery Manufacturing: Gears, shafts, and high-stress parts.

- Medical: Surgical instruments and implants.

- Food and Beverage: Processing equipment and storage containers.

- Electronics and Electrical: Electronic housings and connectors.

Why Choose Our Stainless Steels Bars

Our stainless steel bars are produced using advanced manufacturing techniques that ensure exceptional quality and strength. We provide comprehensive documentation for all our products, guaranteeing reliability and traceability. With a wide selection and customization options, we can meet your specific needs, ensuring you get exactly what you require for your projects.

In addition to our high-quality products, we offer competitive pricing, making our stainless steel bars a cost-effective choice. Our commitment to timely delivery and responsive service ensures you receive your orders promptly and with full support.

Choose our stainless steel bars for unmatched quality, extensive customization, and excellent customer service.