DX53D Galvanized Steel PPGI

DX53D Galvanized Steel PPGI

As a professional galvanized steel manufacturer and supplier, SteelPRO Group provides high-quality DX53D galvanized steel PPGI products, covering a variety of coatings (such as PE, SMP, PVDF, etc.) and types (sheets, coils). Our products comply with international standards like EN 10346, ASTM A653, with rich surface treatments including matte, wood grain, stone grain printing, etc., and are widely used in the construction, home appliance and furniture industries.

- Standards: EN 10346, ASTM A653/A653M, JIS G3302, GB/T 2518

- Grades: DX53D, DX53D+Z, SECC, SGCD, SGHC, FS Type A/B/C

- Technology: Cold rolling, Hot dip galvanizing, Passivation treatment, Pre-painted, etc.

- Substrate: Cold rolled substrate, hot dip galvanized substrate, electro galvanized substrate

- Type: Coated, embossed and printed boards

- Certification: ISO 9001, CE

DX53D Galvanized Steel PPGI

DX53D Galvanized Steel PPGI

Product Specifications

Product Specifications

| Product Name | DX53D Hot dip galvanized steel PPGI |

| Thickness | 0.1mm-5mm, Customized |

| Width | 600mm – 2000mm, Customized Regular Width: 914mm, 1000mm, 1219mm, 1220mm, 1250mm |

| Coil Inner | 508mm – 610mm, Customized |

| Zinc Layer | 30g – 275g/m² |

| Coating Thickness | Top Coating: 15μm-25μm;

Back Coating: 5μm-20μm. |

| Surface Color | According to required RAL. |

| Coating Material | Polyester (PE), Silicone Polyester (SMP), High Durable Polyester (HDP), Fluoropolymer (PVDF) |

| Painting structure | No coating, single-sided coating, double-sided coating |

| Spangle | Big, regular, mini, and zero spangles |

| Surface Treatment | anti-finger print/skin pass/oiled/dry/chromated/Embossed/Lamination |

| Hardness | Soft (normal), hard, full hard(G300-G550) |

| T Bend | ≧ 3 T |

| Reverse Impact | ≧ 9 J |

| Salt Spray Resistance | ≧ 500 H |

| Anti-MEK Wiping | ≧ 100 Times |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Invoicing | By actual weight |

| Delivery Time | 7-15 days |

| Payment | T/T, L/C, Credit Card |

| Port | Tianjin, Qingdao or according to your requirement |

| Packaging Details | In bundles, in bulk, customized packing |

Chemical Compositions

Chemical Compositions

| Element | Carbon (C) | Silicon (Si) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Aluminum (Al) |

|---|---|---|---|---|---|---|

| Content (%) | ≤ 0.12 | ≤ 0.50 | ≤ 0.60 | ≤ 0.10 | ≤ 0.045 | ≥ 0.015 |

Mechanical properties

Mechanical properties

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 270 – 370 |

| Yield Strength (MPa) | ≥ 140 |

| Elongation (%) | ≥ 26 |

| Vickers Hardness (HV) | 100 – 130 |

| Brinell Hardness (HB) | Approx. 50 – 70 |

| Rockwell Hardness (HRB) | ≤ 85 |

| Elastic Modulus (GPa) | ~210 |

Industries & Applications

Industries & Applications

- Construction industry: PPGI sheets are often used to manufacture anti-corrosion roof panels, exterior wall panels and other building materials for industrial and civil buildings, especially for building structures that require long-term anti-corrosion.

- Light industry: In home appliance manufacturing, PPGI sheets are used to produce the outer shells of home appliances such as refrigerators, washing machines, and microwave ovens. They are also widely used in daily necessities such as civil chimneys and kitchen utensils to provide beauty and durability.

- Automotive industry: Its excellent corrosion resistance makes it an ideal material for the automotive industry. It is mainly used to manufacture corrosion-resistant parts for automobiles and extend the service life of vehicles.

- Agriculture, animal husbandry and fishery: It is suitable for the production of grain storage and transportation facilities. It is also widely used in frozen meat and aquatic product storage equipment to meet anti-corrosion and hygiene requirements.

- Commercial application: Due to its anti-corrosion performance and easy processing, PPGI sheets are widely used in the manufacture and transportation of material storage, packaging equipment, etc. to ensure the reliability and safety of materials.

Other Infomation

Other Infomation

Whether to choose single-sided PPGI or double-sided PPGI depends mainly on the specific use environment and requirements of your product.

Single-sided PPGI has a color coating on only one side, and the other side is usually gray or lightly galvanized. Its advantage is that it is low-cost and suitable for applications where only one side needs to be exposed, such as the interior walls of buildings or the inside of roofs, because in these places, the other side does not need special decoration and protection.

Double-sided PPGI has a color coating on both sides, providing better anti-corrosion protection and more beautiful appearance. This type of product is suitable for situations where both sides may be exposed, such as exterior walls or fences, because it can maintain a consistent appearance from any angle and has stronger protection. Double-sided PPGI will cost slightly more, but it can extend the service life of the material, especially when used in humid or highly corrosive environments.

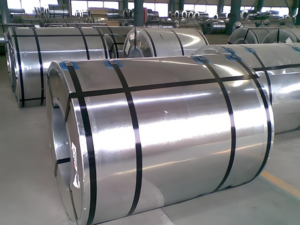

Our Inventory

Our Inventory

SteelPRO Group provides high-quality steel solutions to customers around the world with strong production capacity and advanced manufacturing technology. We have modern production equipment and strict quality control system to ensure that each product can meet customers’ high standards in terms of output and quality. Whether it is galvanizing, coating or size customization, we have flexible production capacity and fast delivery guarantee to meet the scale requirements of various projects.

Main products: steel pipes, steel plates, steel coils, steel bars, steel strips, stainless steel series, carbon steel series, high-strength steel series, nuclear grade steel, galvanized steel, steel for wind and solar energy, etc.

Packing

Packing

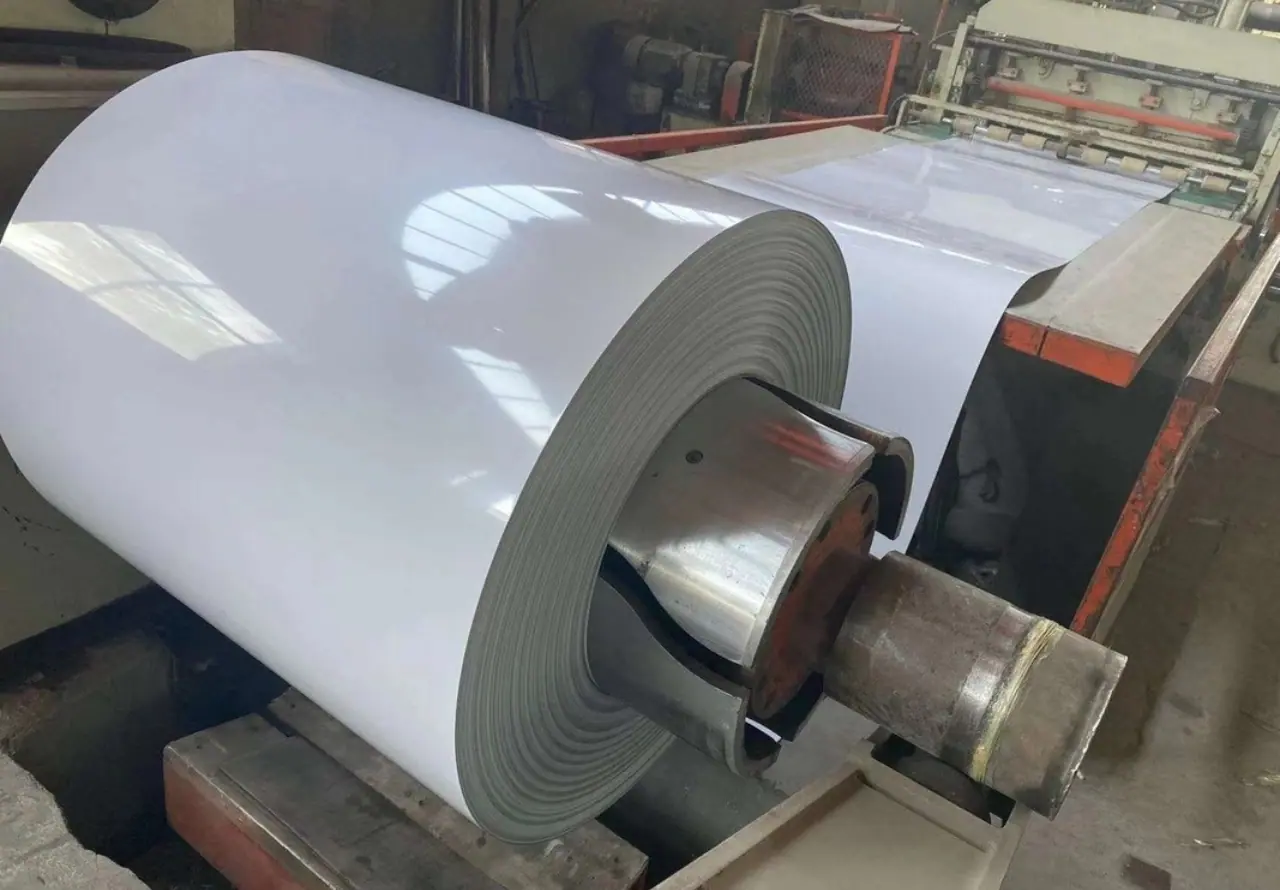

SteelPRO Group’s DX53D galvanized steel PPGI products have been exported to the Middle East, Africa, South America and Southeast Asia. To ensure the safety of the products during long-distance transportation, we use professional packaging: PPGI is first wrapped with a waterproof film and plastic or metal protection strips are added to the edges to prevent collision damage. The coils are securely tied with multiple steel straps and placed on wooden pallets for easy loading and unloading. Finally, the overall lamination provides additional protection to ensure that the product remains intact when it reaches the customer.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

Does SteelPRO Group provide technical support and after-sales service?

Yes, we provide customers with comprehensive technical support and after-sales service, including product usage consultation, installation guidance and maintenance suggestions to ensure customers have a worry-free experience and improve the overall life and performance of the product.

Is SteelPRO Group's DX53D galvanized steel PPGI environmentally friendly?

We are committed to green manufacturing. The emission of harmful substances in the production process of DX53D galvanized steel PPGI is strictly controlled and meets environmental standards. Our materials can be recycled, reducing resource waste and are an environmentally friendly steel choice.

Can SteelPRO Group provide customized galvanized steel PPGI solutions for customers?

Yes. We have rich technical experience and flexible production capabilities. We can provide customized services of different sizes, coating colors and surface treatments according to customer needs to meet the special requirements of various industries and applications.

Can this steel plate be used with other materials?

Yes, DX53D galvanized steel PPGI can be combined with a variety of materials such as concrete and wood. It is very suitable for construction and decoration purposes, improving the overall protection performance and appearance texture of the project.

Can DX53D galvanized steel PPGI be used in humid or seaside environments?

Yes, DX53D galvanized steel PPGI has excellent corrosion resistance in humid or corrosive environments such as the seaside due to the dual protection of the galvanized layer and the coating, making it a very suitable choice.

Can this PPGI steel plate be processed secondary, such as cutting and welding?

Yes, DX53D galvanized steel PPGI has good processing performance and can be processed secondary, such as cutting and bending, but attention should be paid to the protection of the cut surface and welding area to maintain the anti-corrosion effect.

CONTACT

Certificates and Cooperation

Certificates and Cooperation