ABRASION RESISTANT STEEL | WEAR RESISTANT STEEL

Hard. Tough. Long-lasting. Abrasion-Resistant.

Introduction to Abrasion Resistant Steel

Abrasion resistant steel, often abbreviated as AR steel and also known as wear-resistant steel, is a high-carbon alloy steel designed to provide exceptional hardness and toughness. With a composition that includes elements such as carbon and alloying materials, this type of steel undergoes a heat treatment process that enhances its wear resistance, making it highly suitable for applications involving high wear and tear. The hardness of abrasion-resistant steel typically ranges from 400 to 600 BHN.

Despite its higher initial cost, AR steel offers cost-effective long-term performance due to its durability and extended service life. It is widely used in industries such as mining and construction, where its superior abrasion resistance, weldability, and formability are essential.

Benefits of Abrasion Resistant Steel

The benefits of using Abrasion resistant steel are numerous, particularly in industries where high wear and tear are a constant challenge:

- Extended Service Life: AR steel significantly reduces downtime and maintenance costs due to its durability.

- High Wear Resistance: Its ability to withstand severe wear and tear makes it ideal for harsh environments.

- Toughness and Hardness: AR steel offers an excellent balance between hardness and impact toughness, suitable for demanding applications.

- Cost-Effective: Despite its higher initial cost, AR steel’s durability ensures long-term cost savings.

- Weldability: AR steel can be welded using standard methods, allowing for versatile fabrication.

- Formability: Available in both formable and non-formable grades to meet various manufacturing needs.

- Versatile Applications: Suitable for a wide range of industries, including mining, construction, and material handling.

Types of Abrasion Resistant Steel

The names and types of abrasion-resistant steel can vary depending on the manufacturer and the raw materials used, each tailored for specific applications and performance requirements:

- AR200: Known for good formability and moderate wear resistance.

- AR235: Low-alloy steel with good abrasion resistance and moderate hardness for general wear applications.

- AR400: High-carbon steel with high abrasion resistance and hardness for heavy wear and impact applications.

- Mn13: High manganese abrasion-resistant steel, known for its excellent work hardening properties and high toughness.

- NM400: Alloy abrasion-resistant steel with high wear resistance and good impact toughness, typically with a BHN of 360-440.

- NM500: Alloy abrasion-resistant steel, offering higher hardness and wear resistance, with a BHN of 460-520.

Industries & Applications

Abrasion resistant steel is utilized in a variety of applications where high wear resistance is essential. These applications span multiple industries, demonstrating the versatility and robustness of AR steel:

Some common industries and applications include:

Mining Equipment

Construction Equipment

Material Handling

Agricultural Machinery

Industrial Manufacturing

Forestry Equipment

Recycling Plants

Railway Components

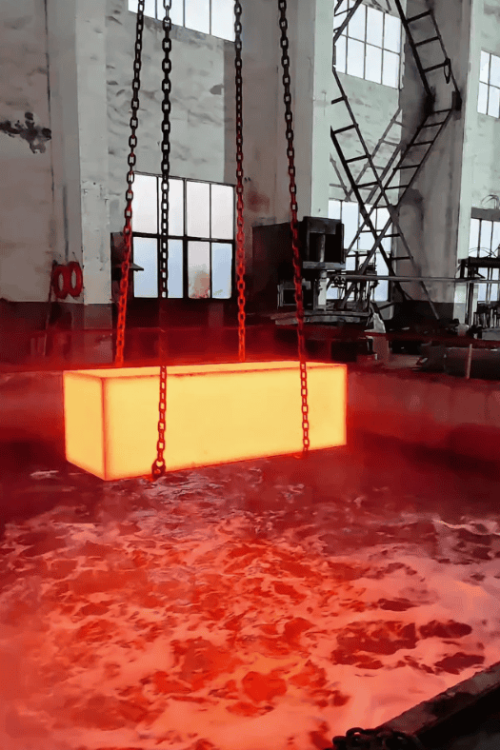

How the Quenching & Tempering Process Makes AR Plates

The quenching and tempering process is essential for producing high-quality abrasion resistant steel plates, enhancing their hardness and toughness for demanding applications:

The quenching and tempering process begins with heating the steel plate to a high temperature to transform its microstructure into austenite. Then, the plate is rapidly cooled with water (quenching), which changes the grain structure to martensite, significantly increasing the steel’s hardness and strength. This process results in through-hardening, ensuring uniform hardness throughout the plate.

Finally, the steel is reheated to a lower temperature (tempering) to reduce brittleness and achieve the desired balance between hardness and toughness. This precise control of temperature and cooling rates is essential to produce high-quality AR plates that meet the stringent demands of wear-resistant applications.

Dimensions & Properties

| Mn13 | NM400 | NM500 | |

|---|---|---|---|

| Yield Strength | 350 MPa (50,763 psi) | ≥ 1,000 MPa (≥ 145,038 psi) | ≥ 1,250 MPa (≥ 181,263 psi) |

| Tensile Strength | 850 MPa (123,275 psi) | 1,250 MPa (181,263 psi) | 1,450 MPa (210,305 psi) |

| Material Standard | ASTM A128 | ASTM A514 | ASTM A517 |

| Vickers Hardness | Approximately 200-250 HV | Approximately 370-430 HV | Approximately 450-550 HV |

Abrasion Resistant Steels When & Where You Need It

Here, you get more than just quality steel. With multiple facilities across the country capable of providing high-strength steels, we can also work with you to manage your inventory, ensuring you get product when and where you need it to keep your production running.

Explore Our Available Steel Products & Grades

Our knowledge and experience give nearly 100% accurate delivery of High Strength Steel, Plain Carbon Steel, Alloy Steel, Stainless Steel products processed and packaged to your exact specifications.

What is AR steel used for?

AR steel is used in industries requiring high wear resistance, such as mining equipment, construction machinery, material handling systems, and agricultural machinery.

What metals are high abrasion resistance?

Metals high in abrasion resistance include high-carbon steel, abrasion-resistant steel, alloy steels with elements like chromium and manganese, and hardened tool steels.

How does your abrasion-resistant steel perform under extreme temperatures and environmental conditions?

Our abrasion-resistant steel performs well under extreme temperatures and harsh environmental conditions, maintaining its hardness and toughness to ensure reliability and longevity.

Comparing initial costs of abrasion-resistant steel to long-term maintenance and replacement costs?

Abrasion-resistant steel has a higher initial cost compared to regular steel, but it significantly reduces long-term maintenance and replacement costs due to its durability and extended service life.

Differences between NM, MN, and AR series abrasion-resistant steel, and which is best for my application?

NM steel is a Chinese-made high-carbon alloy known for its balance of toughness and hardness. MN steel, or high-manganese steel, offers excellent work hardening and impact resistance. AR steel, or Abrasion Resistant steel, is globally recognized for its high hardness and wear resistance. The choice depends on your specific application needs: NM for balanced performance, MN for impact resistance, and AR for overall wear resistance.