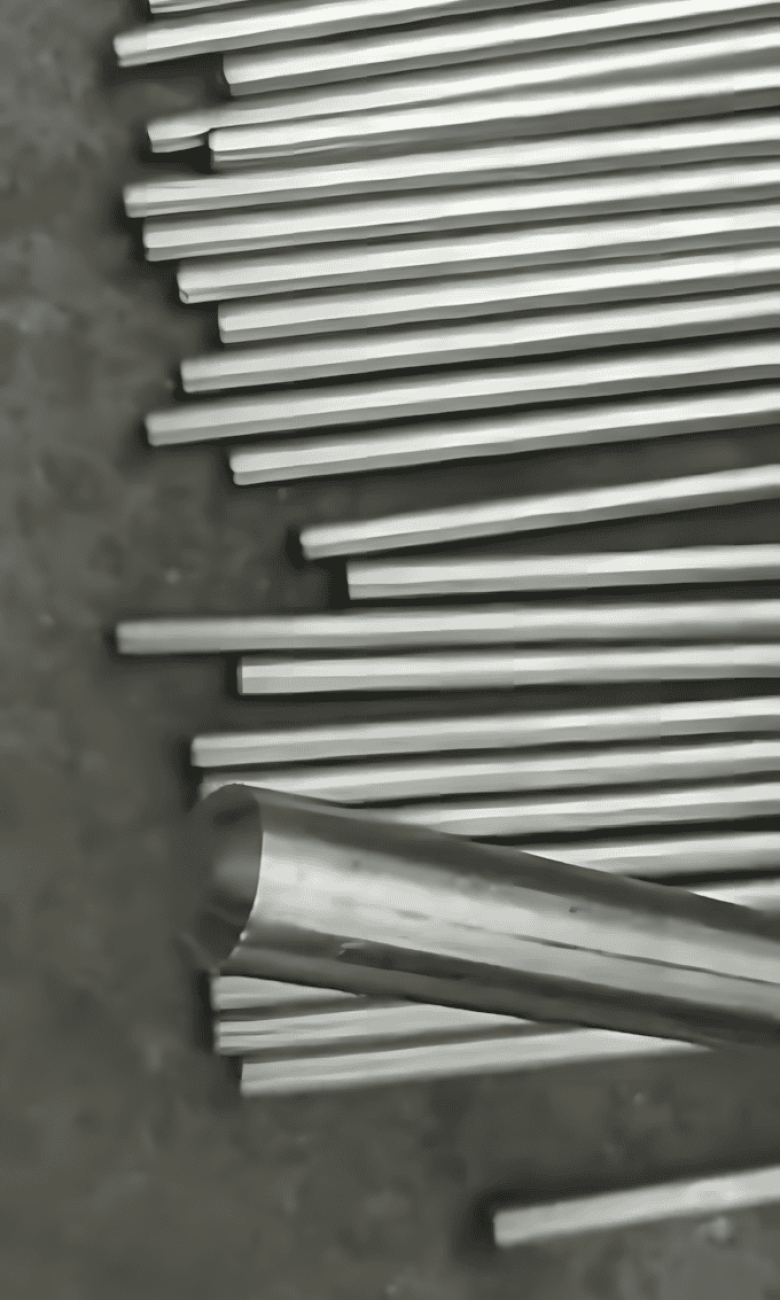

Steel for Manufacture of Appliances

Providing Strength and Durability for Modern Living, Corrosion-Resistant Stainless Steel for Kitchen Appliance Packages, Turning Your Designs into Reality.

ADVANCED HEAT-RESISTANT STEELS FOR APPLIANCE MANUFACTURERS

Crafted to withstand extreme temperatures, our steels offer unmatched thermal stability, ensuring enduring performance in household appliance manufacturing.

PRECISION ENGINEERING, ENDURING PERFORMANCE

From refrigerators to ovens and washers, our meticulous process guarantees precision-engineered solutions for electronics and household appliances, delivering unmatched reliability and longevity.

FORGING NEW FRONTIERS IN APPLIANCE MANUFACTURING

At the forefront of innovation, we pioneer lightweight alloys with exceptional strength and corrosion resistance, setting new benchmarks in appliance manufacturing efficiency.

Types of Steel for Manufacture of Appliances

- Stainless Steel: Known for its corrosion resistance and sleek appearance, stainless steel is widely used in kitchen appliances such as refrigerators, ovens, and dishwashers.

- Galvanized Steel: Offers enhanced durability and corrosion resistance due to its zinc coating, making it suitable for appliance parts and components.

- Aluminized Steel: Provides heat resistance and good formability and is commonly used in the manufacturing of ovens and ranges.

- Carbon Steel: Offers strength and affordability and is used in various kitchen appliances and components.

- Cold Rolled Steel: Provides a smooth finish and precise dimensions, ideal for appliance panels and structures in appliance packages and kitchen setups.

Benefits of Steel for Manufacture of Appliances

- High-Temperature Stability: Engineered to maintain stability in extremely high-temperature environments, it is ideal for manufacturing household appliances such as ovens, freezers, and French door refrigerators that require heat resistance.

- Excellent Strength-to-Weight Ratio: Offers superior strength while remaining lightweight, reducing product weight and improving energy efficiency across a range of appliances.

- Outstanding Corrosion Resistance: Exhibits exceptional resistance to corrosion, protecting against chemical substances and moisture, which enhances product durability and lifespan.

- Precision Engineering for Reliable Products: Ensures reliability and high performance through meticulous engineering and manufacturing processes, meeting the rigorous standards of appliance manufacturers while considering factors like price and door configuration.

Applications

What benefits does stainless steel offer for gas ranges?

How can smart technology be integrated into steel appliances?

Smart technology can enhance appliances like microwaves and refrigerators by offering remote control and energy-saving features, all while maintaining a sleek stainless steel exterior.

Why is wall storage important for kitchen appliances?

Wall storage helps organize steel appliances such as range hoods and microwaves, optimizing kitchen space and accessibility.

How do stainless steel appliances contribute to energy savings?

Stainless steel appliances are known for their energy efficiency and ease of cleaning, reducing overall utility costs.

What role does brand reputation play in choosing steel appliances?

Brand reputation ensures quality and reliability in steel appliance manufacturing, offering peace of mind and dependable customer service from supply to order. This trust in the brand ensures that customers receive consistent quality and reliable support throughout the purchasing process and beyond.