AH420 | High-Strength Shipbuilding Steel

AH420 | High-Strength Shipbuilding Steel

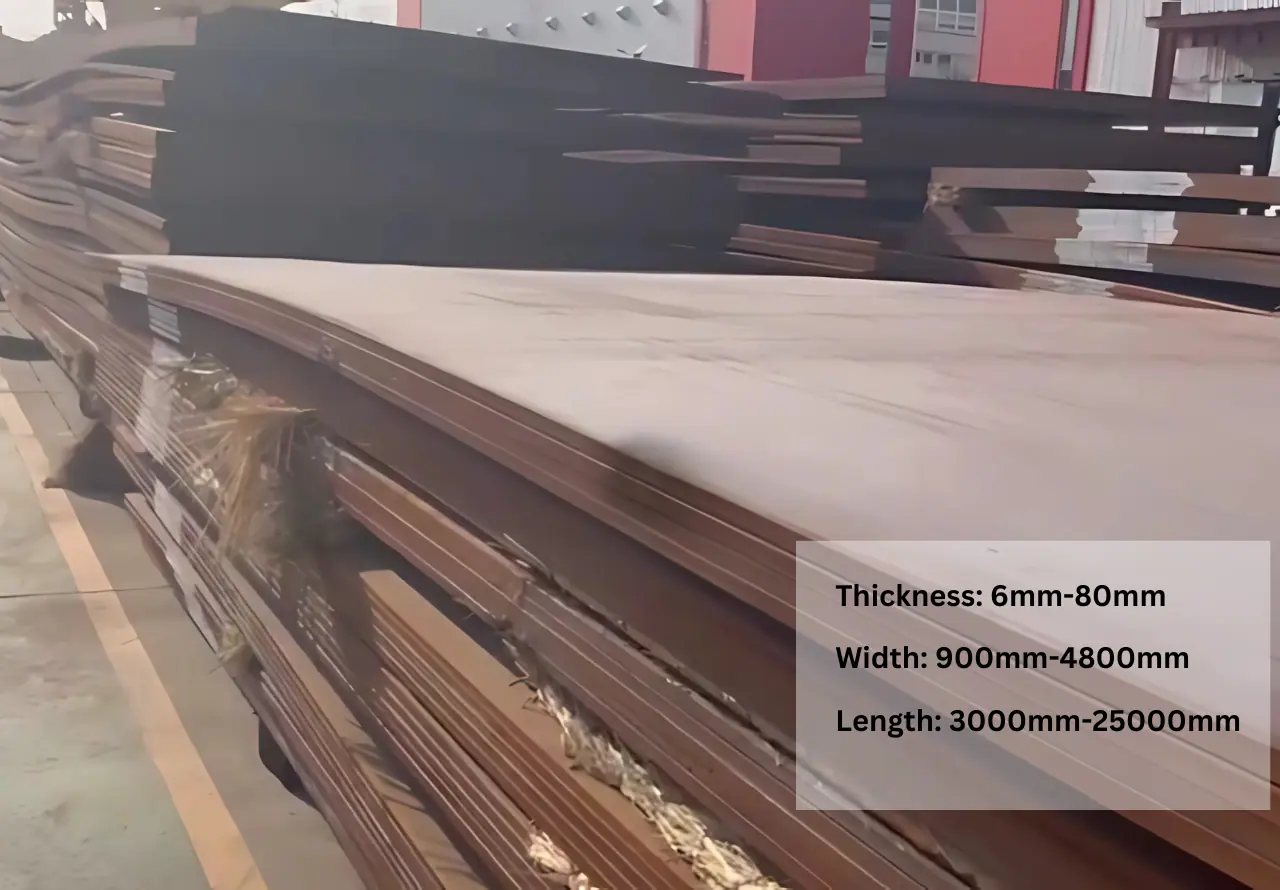

SteelPRO Group has AH420 high-strength shipbuilding steel plates in stock. Offering excellent strength and toughness with good weldability, corrosion resistance, and high durability. Commonly used in shipbuilding, offshore structures, heavy machinery, etc.

Class Cert.: ABS/BV/CCS/DNV/KR/LR/NK/RINA/RS/PRS

Material: Low Alloy Steel

Thickness: 6mm-80mm, or customized

Width: 900mm-4800mm, or customized

Length: 3000mm-25000mm, or customized

Condition of Delivery: TMCP/Q+T/TMCP+T, or as request

Stock: In stock

Origin: Hebei/Henan/Jiangsu, China

Port: Qingdao

Looking for other Grade 420 high-strength steel?

Click here for DH420.

Description

What Is AH420?

AH420 Steel is a high-strength, high-toughness material widely used in shipbuilding and marine engineering. The “A” denotes the toughness rating at room temperature, “H” indicates high strength, and “420” refers to a minimum yield strength of 420 MPa.

AH420 enhances toughness and crack resistance by controlling low phosphorus and sulfur content. The addition of manganese improves impact resistance and hardenability in thick plates, ensuring uniform mechanical properties throughout the structure. It also offers excellent weldability and corrosion resistance, with optional Z-direction properties (e.g., AH420-Z35) to prevent lamellar tearing during welding or heavy loads.

Typical applications include ship hulls, decks, offshore platforms, pipelines, wind turbine foundations, and port machinery. It delivers outstanding durability, fatigue resistance, and structural integrity under harsh conditions.

Characteristics of AH420

- Good balance of strength and toughness

- High wear resistance

- Resistant to cracking under stress

- Excellent weldability

- Easy to machine and shape

Chemical Compositions

| Element | Max % |

|---|---|

| Carbon, C | 0.21 |

| Manganese, Mn | 1.70 |

| Silicon, Si | 0.10–0.55 |

| Sulfur, S | 0.035 |

| Phosphorus, P | 0.035 |

| Copper, Cu | 1.5 |

| Chromium, Cr | 2.0 |

| Nickel, Ni | 2.0 |

| Molybdenum, Mo | 1.0 |

| Aluminum, Al | 0.015 min |

| Niobium, Nb | 0.06 |

| Vanadium, V | 0.10 |

| Titanium, Ti | 0.20 |

| Nitrogen, N | 0.020 |

Physical Properties

| Property | Metric | Imperial |

|---|---|---|

| Density | 7800 kg/m³ | 0.282 lb/in³ |

| Melting Point | 1450 – 1510 °C | 2642 – 2750 °F |

| Thermal Conductivity | 24.9 W/m·K at 100°C | 14.4 BTU/(hr·ft·°F) |

| Electrical Conductivity | ~1.8% IACS | ~1.8% IACS |

| Specific Heat Capacity | 460 J/(kg·K) | 0.11 BTU/(lb·°F) |

| Thermal Expansion Coefficient | 10.3 × 10⁻⁶ /°C (0-100°C) | 5.7 × 10⁻⁶ /°F (32-212°F) |

| Electrical Resistivity | 550 nΩ·m | 550 nΩ·m |

Mechanical Properties

| Thickness (mm) | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) Transverse/Longitudinal | Test Temperature (°C) | Impact Energy (KV J) Transverse/Longitudinal |

|---|---|---|---|---|---|

| 8-260 | ≥ 420 | 530-680 | ≥ 18 | 0 | ≥28/42 |

Industries & Applications

| Industry | Application |

|---|---|

| Shipbuilding | Hull plates, Bulkheads, Deck plates, Structural beams |

| Offshore Structures | Oil platforms, Subsea pipelines, Riser pipes, Jackets |

| Construction | Bridges, High-rise structures, Structural supports, Steel frames |

| Automotive | Truck frames, Chassis components, Suspension parts, Reinforcement bars |

| Energy | Wind turbine towers, Hydropower stations, Boilers, Pressure vessels |

| Mining | Excavator buckets, Dump truck bodies, Crushers, Conveyor belts |

| Oil & Gas | Storage tanks, Refinery components, Heat exchangers, Drilling rigs |

| Heavy Machinery | Cranes, Forklifts, Bulldozers, Loaders |

Machining

Heat Treatment

- Annealing: Heat to 820-850°C, hold for 1-2 hours, then cool slowly in the furnace.

- Hardening: Heat to 950-980°C, hold for 30-60 minutes, then quench in oil or water.

- Tempering: Reheat to 200-400°C (based on required hardness), hold for 1-2 hours, then cool in air.

- Stress Relieving: Heat to 600-650°C, hold for 1 hour, then cool in still air.

Surface Treatment

- Polishing: Enhances surface finish and reduces roughness.

- Electroplating: Adds corrosion resistance with coatings like zinc or chromium.

- Painting/Coating: Provides additional corrosion protection.

- Heat Treatment Coatings: Prevents oxidation during heat treatments.

- Shot Peening: Increases surface hardness and fatigue resistance.

- Anodizing (if applicable): Forms a protective oxide layer for enhanced durability.

*Customization is available upon request.

Our Service

SteelPRO Group – manufacturer and solution provider for special steel, offering multi-industry application solutions and customised services, 100% quality free, accompanying customers in their growth!

Our Quality Control

- Roundness

- Tolerance

- Microstructure

- Non-Destructive Testing

- Destructive Testing

- Process Control

Service Integration Processing

- Welding

- Metal Fabrication

- CNC Machining

- Lathe

- Forming

QUESTION 1

QUESTION 2

QUESTION 3

QUESTION 4

QUESTION 4

CONTACT

CONTACT

Certifications

Other Products

-

-

SteelPRO Group offers FH550 high-strength structural steel plates for shipbuilding....

-

SteelPRO Group offers DH550 high-strength shipbuilding steel plates in stock....

-

SteelPro Group offers FH36 high-strength steel for shipbuilding. It has...