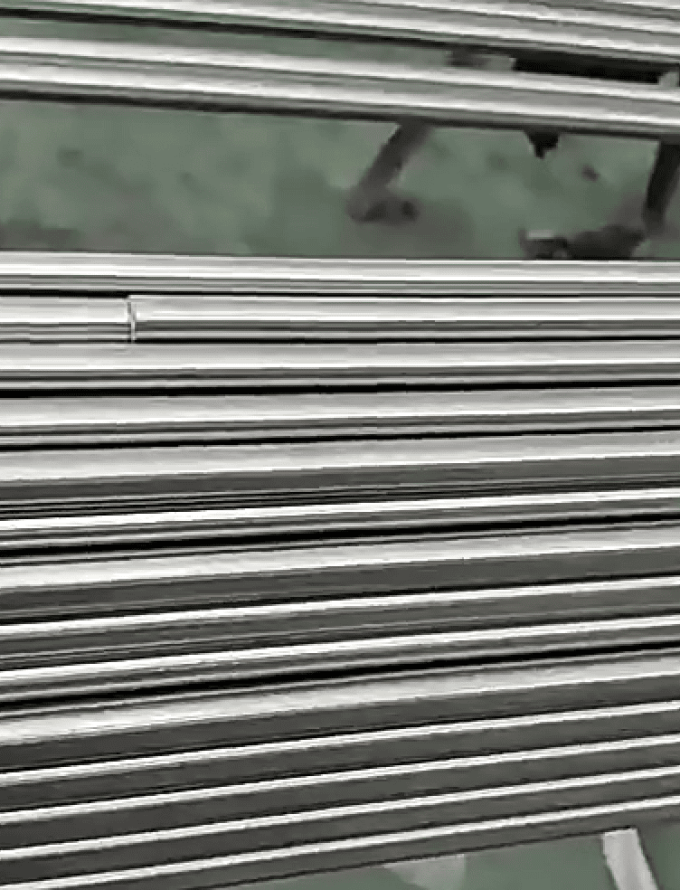

HIGH STRENGTH STEEL BAR

Our high strength steel bars are upheld by a dedication to quality and bolstered by efficient logistics to ensure prompt delivery, all at very competitive rates.

High Strength Steel Bars are widely used in structural applications, heavy construction equipment, building structures, truck frames, aerospace, and oil and gas industries for their high load capacity, corrosion resistance, and performance under extreme conditions.

Reach out to us today to discover more and request a quote tailored to your specifications.

What are High Strength Steel Bar

High Strength Steel Bar Type

| Type | Size Ranges | Applications | |

|---|---|---|---|

| Diameter from 1/4 inch to 24 inches | Shafts, bolts, pins, gears | get a quote |

| Thickness from 1/4 inch to 8 inches | Rails, posts, braces, couplings | get a quote |

| Across Flats (AF) from 1/4 inch to 3 inches | Nuts, fasteners, connectors, specialized fittings | get a quote |

| Width from 1/4 inch to 12 inches | Brackets, frames, reinforcements, supports | get a quote |

High Strength Steel Bar Grades

| Standard | USA | SIZE | |

|---|---|---|---|

| ASTM A29 | 4140 | 1/2'' - 15'' | get a quote |

| ASTM A29 | 4130 | 1 1/4'' - 15'' | get a quote |

| ASTM A572 | Grade 50 | 2/5'' - 12'' | get a quote |

| ASTM A615 | Grade 60 | 2/5'' - 12'' | get a quote |

| ASTM A615 | Grade 75 | 2/5'' - 12'' | get a quote |

| ASTM A706 | Grade 80 | 2/5'' - 12'' | get a quote |

Quality Assurance for High Strength Steel Bars

Regular Quality Inspections

Bend Test: Evaluates ductility.

Chemical Analysis: Verifies grade compliance.

Hardness Testing: Assesses wear resistance (Brinell, Rockwell).

Tensile Testing: Measures yield and tensile strength, elongation.

Extreme Testing

Fatigue Testing: Assesses durability under cyclic loading.

Impact Testing: Evaluates toughness and fracture resistance.

High-Temperature Testing: Assesses performance under extreme heat.

Corrosion Resistance Testing: Evaluates resistance to corrosive environments.

If you have specific requirements, we can customize additional tests to meet your needs.

To ensure the safe and secure transportation of our steel bars, we use robust packaging methods:

Secured Bundling: Bars are securely bundled with steel straps and wooden supports. Finished products are shipped in wooden crates.

Protective Coatings: Our steel bars are coated to prevent corrosion and damage during transit. Additional coating options are available upon request.

Labeling and Documentation: Each shipment is clearly labeled and comes with detailed documentation for easy tracking.

Several factors can influence the performance of high strength steel bars:

Corrosion: Exposure to moisture and corrosive environments can weaken steel bars over time.

Chemical Exposure: Contact with certain chemicals can lead to corrosion and strength degradation.

Mechanical Damage: Physical impacts during handling and installation can affect structural integrity.

Temperature Variations: Extreme temperatures can cause expansion or contraction, impacting performance.

Proper storage is crucial to maintaining the quality and performance of high strength steel bars:

Elevation: Use wooden pallets or supports to keep bars off the ground and avoid moisture.

Organized Stacking: Stack bars neatly with adequate spacing for easy access and inspection.

Ventilation: Ensure adequate ventilation to prevent condensation and the buildup of moisture.

Dry Environment: Store steel bars in a dry, covered area to protect them from moisture and corrosion.

Regular Inspections: Inspect regularly for corrosion or damage and address promptly to maintain quality.

Usage & Application of High Strength Steel Bar

High Strength Steel Bars are essential across various industries for their unparalleled strength, durability, and performance:

- Construction Companies: Reinforced concrete structures, bridges, and high-rise buildings.

- Automotive Manufacturers: Chassis, suspension systems, and safety parts.

- Heavy Machinery Producers: Cranes, bulldozers, and other heavy equipment.

- Oil and Gas Corporations: Drilling rigs, pipelines, and offshore structures.

- Aerospace Firms: Aircraft landing gear, structural components, and engine parts.

- Mining Companies: Drills and loaders for enhanced durability.

- Marine Industries: Shipbuilding and offshore platforms.

Why Choose Our High Strength Steel Bar

Our high strength steel bars, made from top-quality materials, ensure superior strength and durability for a wide range of applications. We provide full traceability with thorough documentation, including raw material test certificates and final dimensional statements. Our efficient logistics and dedicated customer support ensure prompt delivery and quick, helpful responses to your inquiries.

We offer a broad range of steel bar sizes and grades, providing customized solutions tailored to your specific project needs. With competitive pricing, we guarantee the best value, unmatched performance, and complete satisfaction for your investment.

Choose us for high strength steel bars that exceed industry standards and deliver exceptional results for your projects.