Q390 STEEL | STRUCTURAL STEEL

Q390 STEEL | STRUCTURAL STEEL

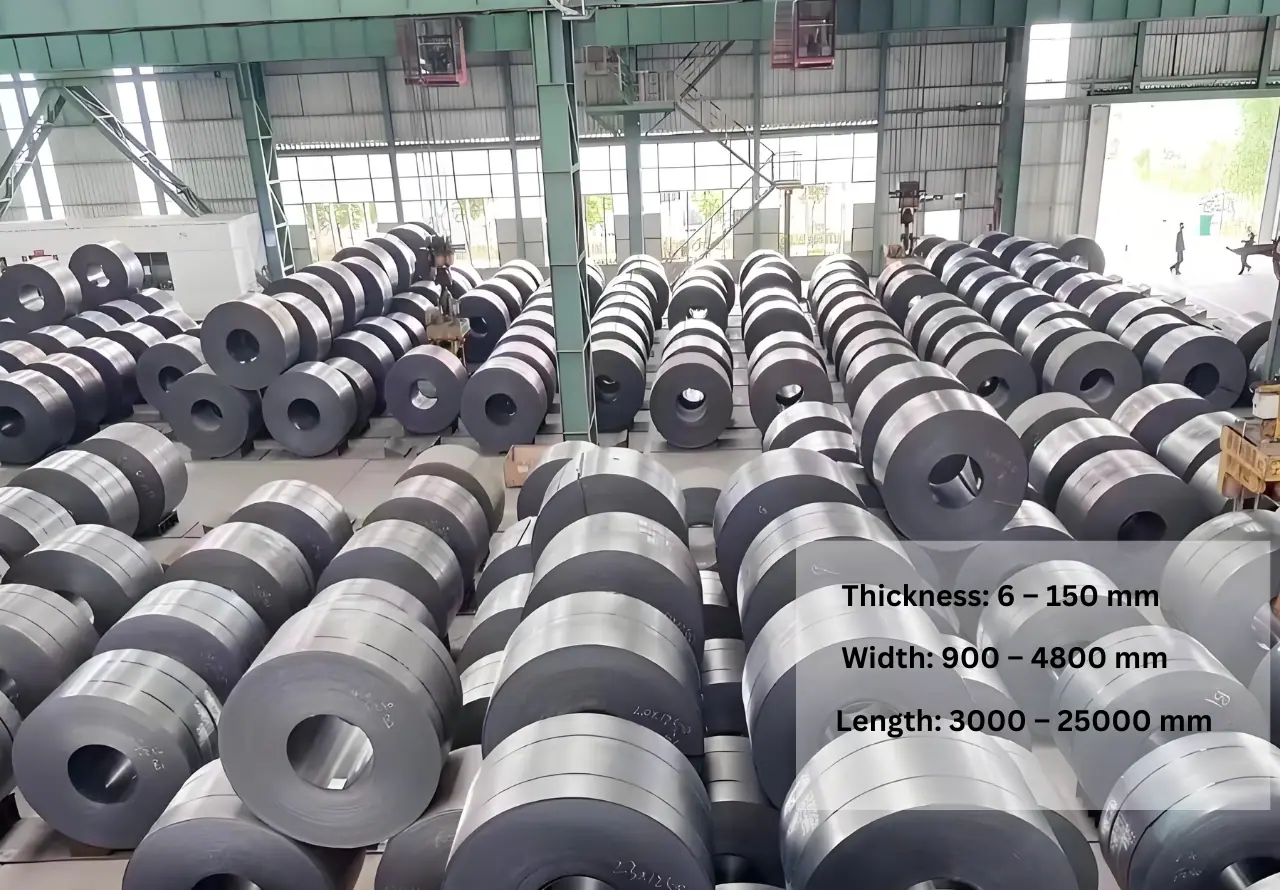

Q390 is a high-strength, low-alloy structural steel widely used in engineering and construction. The “Q” denotes the yield point, while “390” indicates a yield strength of 390 MPa. This steel offers high strength, good weldability, and excellent toughness, making it ideal for bridges, buildings, and heavy machinery. Its equivalent grades include ASTM A572 Grade 55 and JIS G3106 SM490. We can produce Q390NB/C/D/E products in thicknesses of 6 to 150 mm according to GB/T 1591.

Description

What is Q390

Q390 is a high-strength low-alloy structural steel primarily used in various engineering structures. It is composed of approximately 0.18% carbon, 1.60% manganese, 0.035% phosphorus, and 0.035% sulfur, with the balance being iron. Typically supplied as solid plates, Q390 features high strength, good weldability, toughness, and wear resistance. It also has subcategories Q390A, Q390B, Q390C, Q390D, and Q390E. It is mainly used in construction, bridges, and heavy machinery. Processed through hot rolling, Q390 can be further categorized into subgrades based on specific mechanical properties.Characteristics of Q390 Steel

Chemical Compositions

| Element | Percentage (%) |

|---|---|

| Carbon (C) | 0.20 max |

| Silicon (Si) | 0.55 max |

| Manganese (Mn) | 1.00 – 1.60 |

| Phosphorus (P) | 0.035 max |

| Sulfur (S) | 0.035 max |

| Chromium (Cr) | 0.30 max |

| Nickel (Ni) | 0.30 max |

| Copper (Cu) | 0.30 max |

Physical Properties

| Property | Metric | Imperial |

|---|---|---|

| Density | 7.85 g/cm³ | 0.284 lb/in³ |

| Melting Point | 1400°C – 1450°C | 2552°F – 2642°F |

| Thermal Conductivity | 35 W/m·K | 20.2 BTU·in/hr·ft²·°F |

| Specific Heat Capacity | 500 J/kg·K | 0.12 BTU/lb·°F |

| Thermal Expansion Coefficient | 12 x 10⁻⁶ /°C | 6.7 x 10⁻⁶ /°F |

| Electrical Resistivity | 0.15 x 10⁻⁶ Ω·m | 0.15 x 10⁻⁶ Ω·m |

Mechanical Properties

| Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Tensile Strength | 490 – 620 MPa | 71 – 90 ksi |

| Yield Strength | ≥ 390 MPa | ≥ 56.6 ksi |

| Brinell Hardness (HB) | 140 – 190 HB | 140 – 190 HB |

| Rockwell Hardness (HRC) | 20 – 25 HRC | 20 – 25 HRC |

| Vickers Hardness (HV) | 150 – 200 HV | 150 – 200 HV |

| Elongation | ≥ 20% | ≥ 20% |

Data After Quenching and Tempering(QT)

| Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Tensile Strength | 600 – 750 MPa | 87 – 109 ksi |

| Yield Strength | ≥ 460 MPa | ≥ 66.7 ksi |

| Impact Toughness | 27 J at -20°C | 20 ft·lbf at -4°F |

| Elongation | ≥ 18% | ≥ 18% |

| Reduction of Area | 50% | 50% |

| Elastic Modulus | 210 GPa | 30.5 Msi |

Industries & Applications

| Industry | Products |

|---|---|

| Bridges and Building Structures | Girders, Trusses, Support Beams, Columns |

| Automotive and Truck Parts | Chassis, Frames, Suspension Components, Reinforcements |

| Railroad Cars and Cargo Containers | Railroad Car Bodies, Underframes, Side Panels, Cargo Container Walls |

| Structural Tubing | Frameworks, Support Structures, Scaffolding, Pipelines |

| Lighting Standards | Streetlight Poles, Floodlight Columns, Traffic Signal Posts, Public Area Lighting |

| Transmission Poles | Electrical Power Poles, Communication Towers, Utility Poles, Telecommunication Masts |

| Heavy Machinery | Excavator Booms, Crane Arms, Mining Equipment Frames, Forestry Machinery Chassis |

| Marine and Offshore Structures | Ship Hulls, Offshore Platform Structures, Deck Supports, Marine Piles |

| Industrial Manufacturing | Heavy-duty Conveyor Systems, Large Industrial Presses, Furnace Structures, Steel Mill Equipment Frames |

Machining

Q390 Heat Treatment

- Heating: Heat the steel to 880-920°C (1615-1690°F) to achieve uniform austenitization.

- Soaking: Hold at the target temperature for 30-60 minutes, depending on thickness, to ensure even heat distribution.

- Quenching: Rapidly cool in water or oil to increase hardness and strength.

- Tempering: Reheat to 550-650°C (1020-1200°F) and hold for 1-2 hours to relieve internal stresses and improve toughness.

- Cooling: Allow the steel to cool in air to achieve a balance of strength, toughness, and ductility.

Q390 Surface Finish Processing

- Shot Blasting: Clean the surface using steel shots to remove scale, rust, and contaminants.

- Painting: Apply a layer of primer followed by a topcoat for corrosion protection.

- Galvanizing: Coat with zinc to protect from corrosion, especially in harsh environments.

- Polishing: Improve the surface finish to achieve a smooth and reflective appearance.

Custom grades can be provided according to requirements.

Our Service

SteelPRO Group – manufacturer and solution provider for special steel, offering multi-industry application solutions and customised services, 100% quality free, accompanying customers in their growth!

Our Quality Control

- Roundness

- Tolerance

- Microstructure

- Non-Destructive Testing

- Destructive Testing

- Process Control

Service Integration Processing

- Welding

- Metal Fabrication

- CNC Machining

- Lathe

- Forming

QUESTION 1

QUESTION 2

QUESTION 3

QUESTION 4

QUESTION 4

CONTACT

CONTACT

Certifications

Other Products

-

-

SteelPRO Group offers FH550 high-strength structural steel plates for shipbuilding....

-

SteelPRO Group offers DH550 high-strength shipbuilding steel plates in stock....

-

SteelPro Group offers FH36 high-strength steel for shipbuilding. It has...