Dx52d | Galvanized PPGI Steel

Dx52d | Galvanized PPGI Steel

DX52D (1.0350) PPGI is a pre-painted galvanized steel classified as low-carbon steel for cold forming. The PPGI coating provides protection and enhances aesthetics, ideal for products in harsh environments or needing specific colors. DX52D complies with EN 10346 and follows EN 10169 for coating quality when pre-painted. Equivalent grades include ASTM A653 CS Type and JIS G3302 SGCD. It offers good formability and corrosion resistance, suitable for drawing, stamping, and forming. Commonly used in roofing, appliance exteriors, and industries needing aesthetics and protection.

Description

Why Choose PPGI DX52D Galvanised Steel

When you choose DX52D, you get a steel combining formability and strength. It’s ideal for deep drawing, bending, and shaping. We recommend DX52D for its balance of flexibility and durability, making it perfect for a variety of industries. The PPGI process, which involves pre-painting the galvanized steel, enhances both its corrosion resistance and aesthetic appeal, ensuring durability in harsh environments. What sets PPGI DX52D apart is its flexibility, smooth surface, and ability to handle further coatings without losing quality. Whether for construction, appliances, or decorative elements, you’ll get a tough, reliable product tailored to your needs. By choosing DX52D, you’re ensuring long-lasting performance and a solution made for your project.Products of Dx52d Galvanised PPGI Steel We Offer

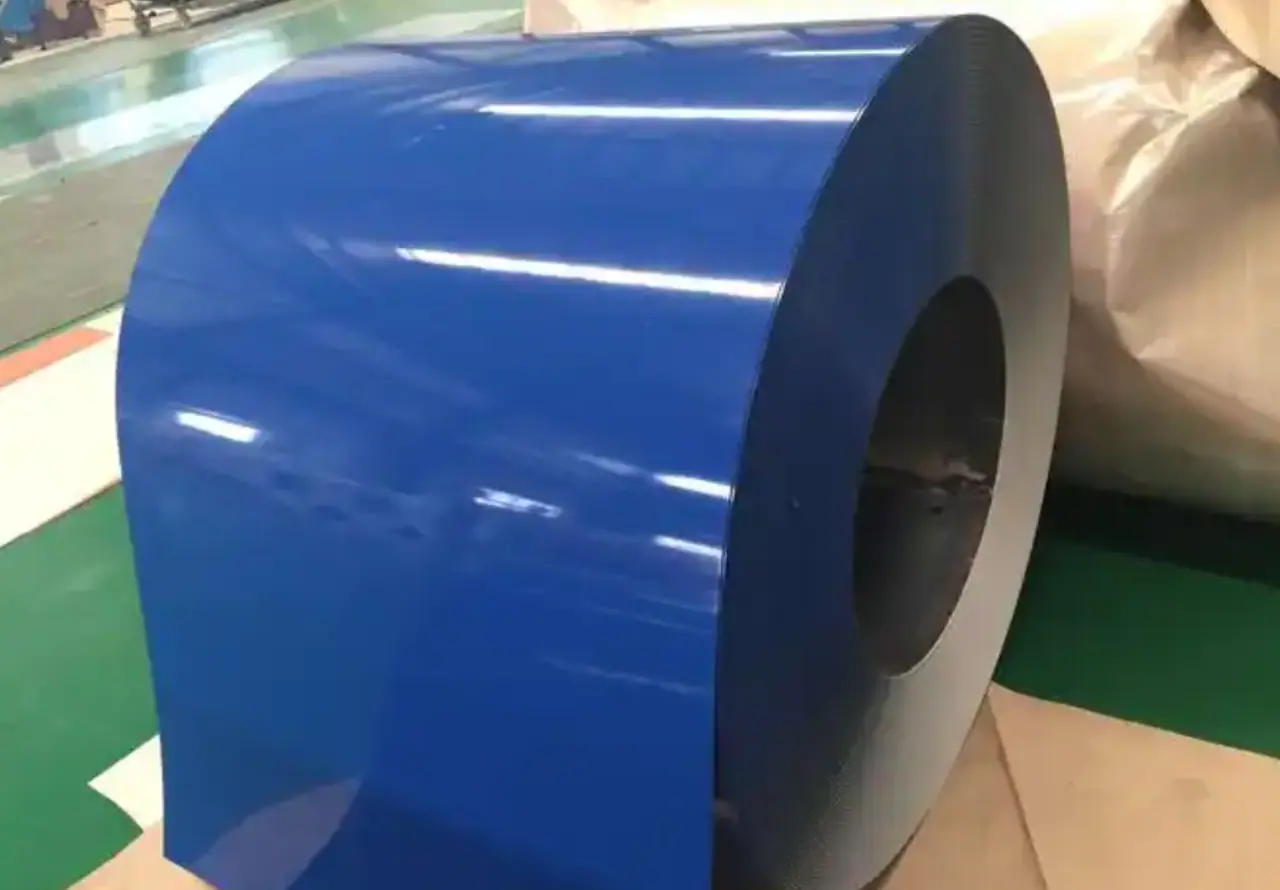

- Coils: Continuous Coils, Pre-painted Coils, Hot-dip Galvanized Coils, Electro-galvanized Coils

- Cut-to-Size (cut-to-length up to 6 meters)

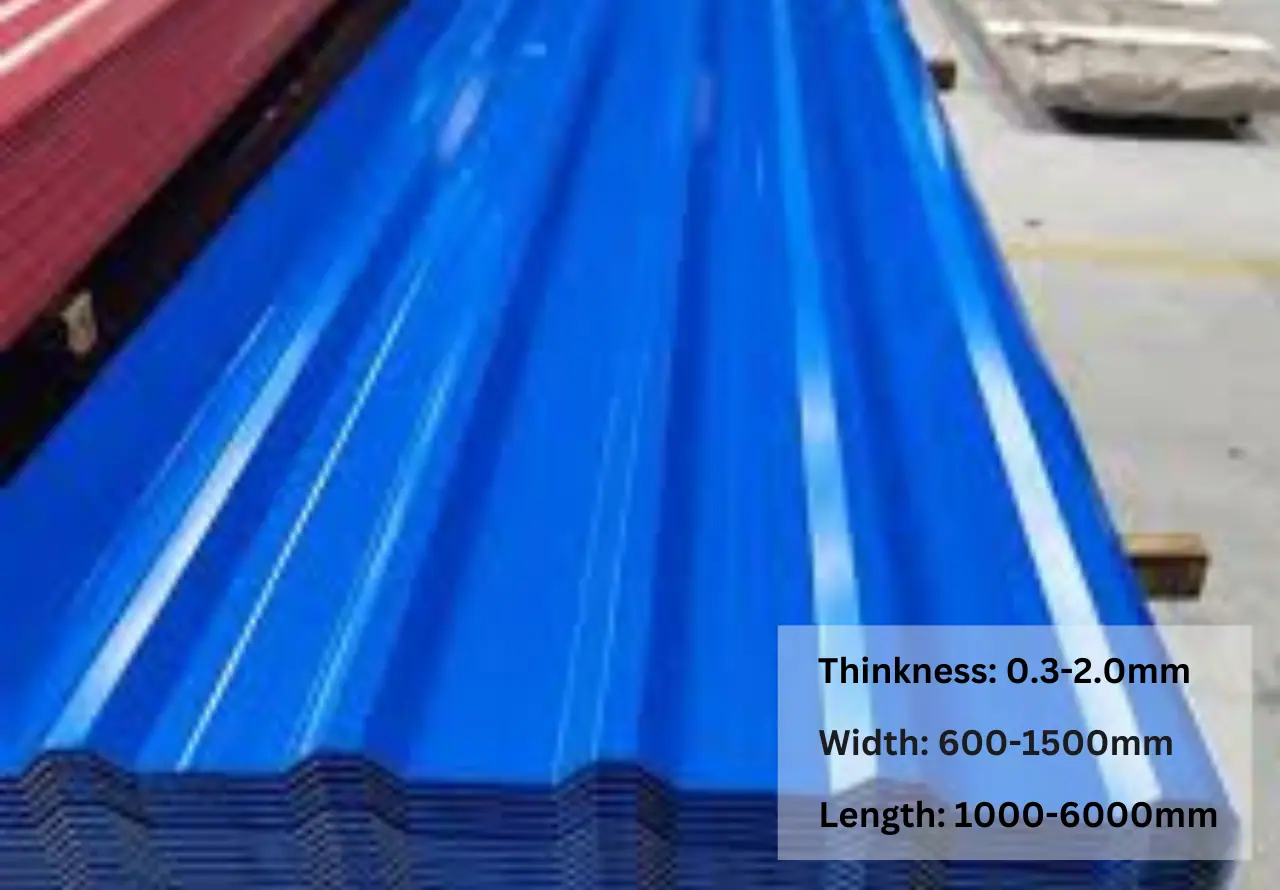

- Sheets: Corrugated Sheets, Plain Sheets

- Plates: Flat Plates, Structural Plates

- Slitted Strips: Strips for Tubes, Narrow Strips, Steel Bands

Product Specification

| Category | Details |

| Quality Standard | EN 10346, GB /T 2518, JIS G 3302, ASTM A653, BS EN 10142 |

| Certifications | ISO9001, 2000 |

| Thickness | 0.3 mm – 2.0 mm |

| Width | 600 mm – 1500 mm |

| Length | 1000 mm – 6000 mm |

| Inner Diameter | 508 mm – 610 mm |

| Weight | Depends on length and width |

| Tolerances | Thickness Tolerance(±0.02 mm to ±0.10 mm), Width Tolerance(±2 mm to ±5 mm), Length Tolerance(±5 mm to ±10 mm) |

| Hardness | Soft (normal), hard, full hard (G300-G550) |

| Base Material | Hot-dip galvanized steel |

| Shapes | We have Coils, Cut-to-Size sheets and plates, Slitted Strips |

| Galvanizing Method | Hot-dip galvanizing, electro-galvanizing, galvannealing |

| MOQ (Minimum Order Quantity) | 5 tons (according to the actual tonnage) |

| Lead Time | Typically 7-20 days |

| Price Terms & Payment | Based on customer requirements, T/T, L/C |

| Ports | Qingdao, Lianyungang, Dalian |

| Export Countries | Southeast Asia, Central Asia, Europe, Russia, South America, Middle East, etc, |

| Shipping Method | Offers Sea, Air and Customised Shipping |

Ladle Analysis Chemical Composition

| Element | Minimum (%) | Maximum (%) |

|---|---|---|

| Carbon (C) | 0 | 0.12 |

| Silicon (Si) | 0 | 0.5 |

| Manganese (Mn) | 0.1 | 0.6 |

| Phosphorus (P) | 0 | 0.1 |

| Sulfur (S) | 0 | 0.045 |

| Aluminum (Al) | 0 | 0.035 |

| Nitrogen (N) | 0 | 0.012 |

| Titanium (Ti) | 0 | 0.3 |

Mechanical Properties of DX52D Galvanized Steel

| Coating Type | Standard | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|---|

| Zinc (Z) | EN 10346 | ≥140 | 270-420 | ≥26 (for t ≤ 0.7mm) |

| Zinc-Iron Alloy (ZF) | EN 10346 | ≥140 | 270-420 | ≥26 (for t ≤ 0.7mm) |

| Aluminum-Zinc (AZ) | EN 10346 | ≥140 | 270-420 | ≥26 (for t ≤ 0.7mm) |

| Aluminized (AS) | EN 10346 | ≥140 | 270-420 | ≥26 (for t ≤ 0.7mm) |

| Electro-Galvanized (EG) | ASTM A653 | ≥140 | 270-420 | ≥26 (for t ≤ 0.7mm) |

| Galvannealed (GA) | JIS G3302 | ≥140 | 270-420 | ≥26 (for t ≤ 0.7mm) |

| Organic Coated (OC) | EN 10169 | ≥140 | 270-420 | ≥26 (for t ≤ 0.7mm) |

| Hot-Dip Galvanized (HDG) | ASTM A653 | ≥140 | 270-420 | ≥26 (for t ≤ 0.7mm) |

| Pre-painted Galvanized (PPGI) | EN 10169 | ≥140 | 270-420 | ≥26 (for t ≤ 0.7mm) |

| Ceramic Coated (CC) | EN 10346 | ≥140 | 270-420 | ≥26 (for t ≤ 0.7mm) |

Industries & Applications

- Construction: Roofing sheets, wall panels, gutters, downspouts, garage doors, metal fences, steel partitions, corrugated sheets, window frames, siding panels, steel doors, ventilation ducts

- Automotive: Car body panels, truck and trailer side panels, engine covers, chassis components, automotive housings, door frames, roof racks

- Appliances: Refrigerator doors, washing machine drums, oven panels, microwave oven casings, dishwasher panels, air conditioner housings, water heater tanks

- Agriculture: Barn roofs, silo panels, grain bins, farm fencing, greenhouse structures, animal feed storage containers, irrigation system components

- Energy: Solar panel mounting frames, wind turbine housings, electrical enclosures, cable trays, power transmission towers

- Decorative and Signage: Building facades, advertising billboards, architectural trims, outdoor signs, metal cladding for storefronts, interior decorative panels

- Furniture: Metal chairs, steel desks, shelving units, lockers, filing cabinets, metal bed frames, outdoor furniture, storage cabinets

Packing

Packaging We Offered

For DX52D Galvanised Steel PPGI, packaging is crucial to ensure product integrity during transport and storage, given the delicate nature of the pre-painted finish. We offer the following standard packaging options:

- Moisture-proof packaging: The material is wrapped with a plastic film or moisture-resistant paper to prevent any water or humidity damage.

- Steel Strapping: The coils or sheets are securely strapped with steel bands to prevent shifting or loosening during transportation.

- Metal Edge Protectors: Metal or plastic edge guards are used to protect corners from damage during handling.

- Wooden Pallets: Coils or sheets are placed on sturdy wooden pallets for easy handling with forklifts and to provide stability during transit.

- Plastic Film and Waterproof Layers: Additional layers of plastic wrap or waterproof material are applied to further protect the surface from moisture or scratches.

All our packaging methods can be customized to meet specific customer needs, ensuring the protection of the PPGI material according to your requirements.

Machining

DX52D Galvanised Steel Surface Finishes

- Compliance:

All surface treatments are RoHS and REACH compliant, free from phthalates and hexavalent chromium (Cr 6+). - Coating Types:

+Z, +ZF, +ZA, +ZM, +AZ, +AS, +EG, +OC, +CC, +HDG

(Coating thickness range: Z100 to Z275, with a tolerance of ±10% to ±20%) - Additional Surface Treatments:

Passivation, oiling, or pre-painted (color coating) treatments can be applied for enhanced corrosion resistance and aesthetics. - Spangle Types: Zero Spangle、Small Spangle、Regular Spangle、Big Spangle

Surface Quality:

- Normal Surface (A):

Allows minor defects like small scratches, pitting, and uneven coating. Spangles are more visible, and the surface has a matte finish. Suitable for non-decorative applications. - Improved Surface (B):

Achieved through skin passing, this surface is smoother with fewer defects. It is ideal for applications requiring higher aesthetics, such as appliances. The surface has a slight gloss and is suitable for further coating or painting.

Colors: The typical paint is polyester (PE), with common back paint colors in white or grey. Colors can be customized according to RAL color charts or customer samples.

White Rust Prevention: Store DX52D in dry, well-ventilated conditions to prevent moisture buildup between sheets or coils. If condensation occurs, separate materials and allow them to dry to avoid white rust formation.

Dx52d Galvanized Steel PPGI Manufacturer

- Comprehensive Processing Services:

We offer hot-dip galvanizing, cold processing, welding, punching, cutting, bending, and uncoiling, all tailored to your needs. - Strict Quality Control:

We ensure quality at every stage with tests like magnetic thickness, salt spray, and tensile strength to meet international standards. - Reliable Raw Materials and Stable Supply:

With three factories and top-tier suppliers, we guarantee a steady supply of high-quality raw materials to meet demand. - Fast, Customized Solutions:

We respond quickly to inquiries, strictly follow customer tolerances, and provide a reliable lifetime warranty on all products. - Competitive Pricing:

Our pricing offers exceptional value without compromising on quality, making us a cost-effective choice. - Flexible Packaging and Transparent Shipping:

We offer customizable packaging for safe delivery and transparent shipping for complete peace of mind. - Comprehensive Product Range:

We also supply stainless steel, high-strength plates, tubes, coils, pipes, wires, bars, rods, strips, and channels.

Our Service

SteelPRO Group – manufacturer and solution provider for special steel, offering multi-industry application solutions and customised services, 100% quality free, accompanying customers in their growth!

Our Quality Control

- Roundness

- Tolerance

- Microstructure

- Non-Destructive Testing

- Destructive Testing

- Process Control

Service Integration Processing

- Welding

- Metal Fabrication

- CNC Machining

- Lathe

- Forming

Can You Customize the PPGI Color?

Yes, we can customize the PPGI color based on your needs. The most common custom colors are selected from the RAL color chart, which includes a wide range of shades such as white, grey, blue, red, green, and brown. We can also match colors based on specific customer samples if you need something unique for your project.

What’s the Lead Time for Orders?

1. The lead time starts once we receive your deposit. 2. Final order confirmation is required to proceed with production. Typically, delivery takes 5-20 days depending on order size and customizations. If this doesn’t meet your expectations, please contact us through our website, and we’ll do our best to accommodate your needs.

What Coating Thickness Options Are Available?

For DX52D Galvanised Steel PPGI, the coating thickness options typically range from Z100 to Z275 for zinc coatings. This translates to a zinc coating weight of 100g/m² to 275g/m² per side. The specific coating thickness can be customized based on your application requirements, with a tolerance of ±10% to ±20%.

Can You Provide Samples for Quality Evaluation Before Placing a Bulk Order?

Yes, we can provide samples of DX52D Galvanised Steel PPGI for quality evaluation before you place a bulk order. Please note that while the samples are free, shipping costs are typically covered by the customer. Simply reach out to us with your sample request, and we’ll arrange the delivery.

How do You Handle Orders with Specific Tolerance or Thickness Requirements Outside Standard Ranges?

We handle specific tolerance or thickness requirements by customizing the production process to meet your needs. Just provide the details, and we’ll ensure your specifications are followed.

What Testing Methods Are Used to Ensure Long-Term Corrosion Resistance in Different Environments?

We use several testing methods to ensure long-term corrosion resistance, including salt spray testing, humidity resistance tests, and coating thickness measurements. These tests simulate harsh environmental conditions to guarantee the durability of DX52D Galvanised Steel PPGI in various settings.

CONTACT

CONTACT

Certifications

Other Products

-

-

SteelPRO Group offers FH550 high-strength structural steel plates for shipbuilding....

-

SteelPRO Group offers DH550 high-strength shipbuilding steel plates in stock....

-

SteelPro Group offers FH36 high-strength steel for shipbuilding. It has...